Raw coal upgrading device and method with combination of drying and dry separation

A technology for upgrading equipment and raw coal, which is applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., can solve the problems that investors are difficult to accept, large investment, etc., and achieve the advantages of easy promotion and application, less investment, and avoiding energy waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

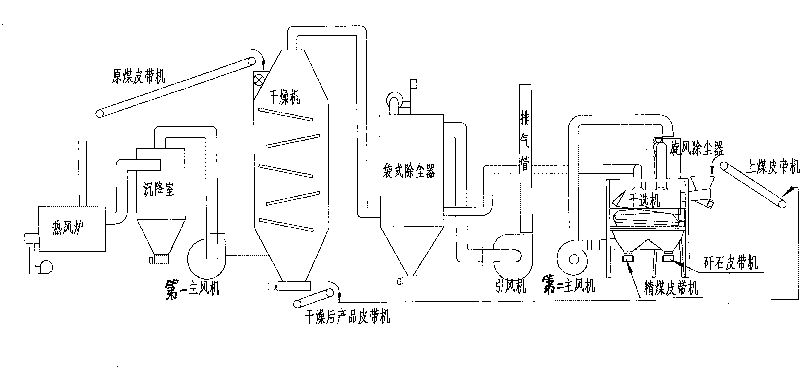

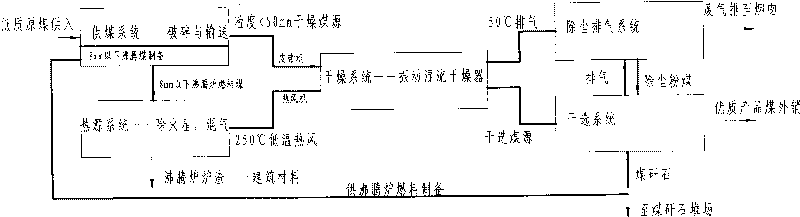

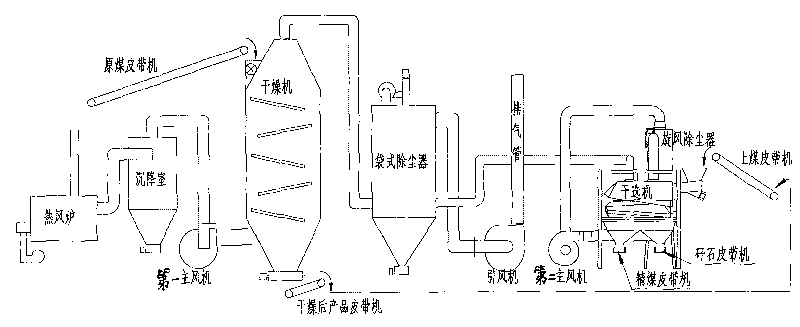

[0027] Attached below figure 1 and figure 2 To illustrate the technical solution of the patent of the present invention, in the following specific embodiments, unless otherwise specified, the components or methods used are all conventional components and methods, and the connection relationship between various conventional components uses conventional connections.

[0028] Such as figure 1 Shown in is a dry dry selection combined raw coal upgrading equipment, which includes a coal supply system, a hot air system, a drying system, a dust removal exhaust system and a dry separation system. The coal supply system can be divided into two parts: dry raw coal supply and hot blast furnace coal supply. The coal supply system uses raw coal transportation device to supply raw coal to the hot air system and drying system respectively; figure 1 The raw coal transportation device shown in is a raw coal belt conveyor, and chain transportation mechanisms and other conventional material tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com