High-pressure roll selective smashing and sorting method for middlings

A high-pressure roller and selective technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as combustion instability, boiler efficiency reduction, environmental pollution, etc., to reduce coal transportation costs, reasonable recovery and Utilization, the effect of a high degree of product dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

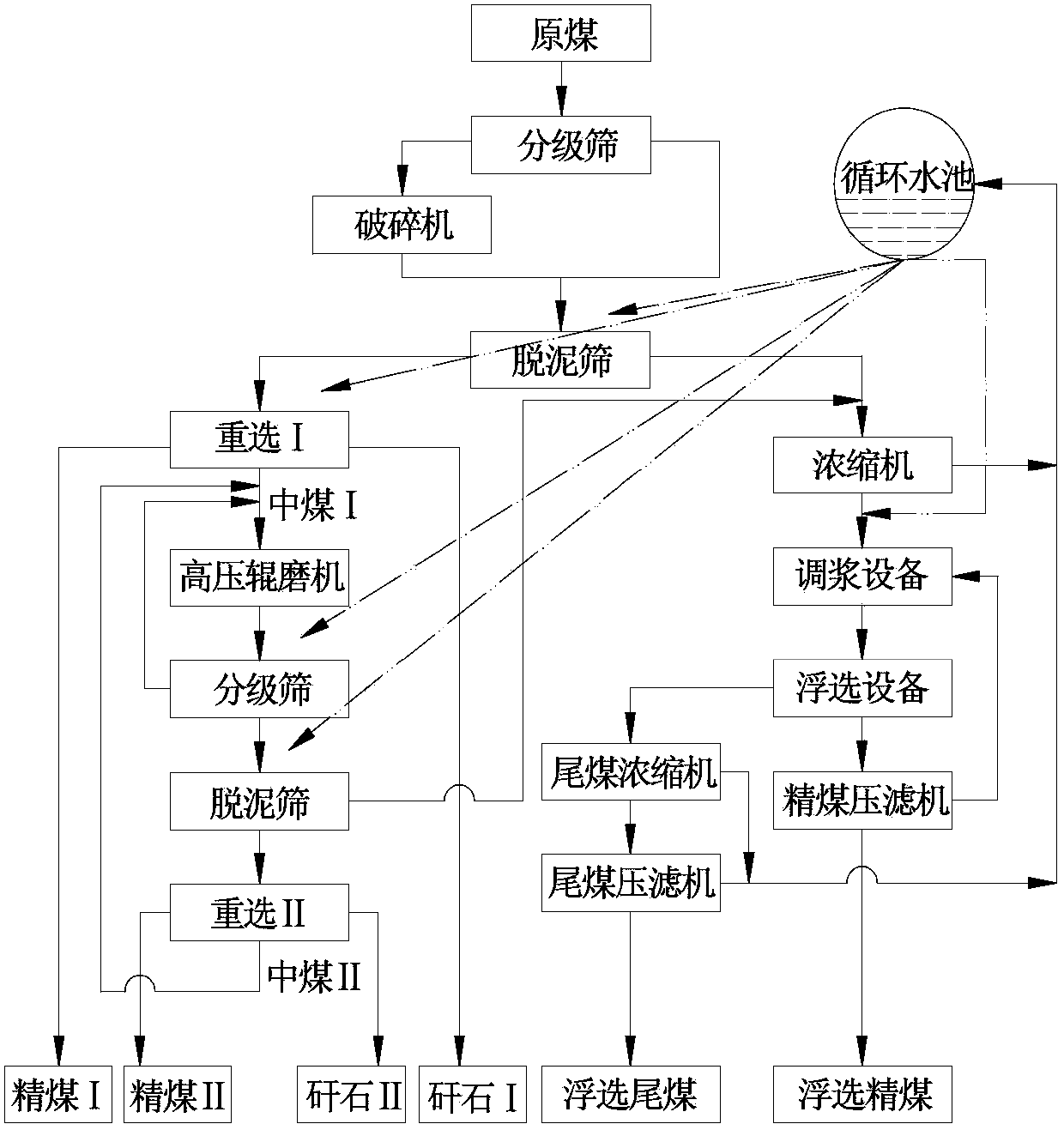

[0023] The raw coal is coking coal with an ash content of 18.59%. The coal washing plant is a mine-type coal washing plant with a processing capacity of 4 million t / a. The high-pressure roller mill is used to carry out ultra-fine crushing of medium coal and then sorting. The process steps are as follows:

[0024] (1) Raw coal enters a sieve with a sieve hole of 200mm. The material on the sieve is crushed by a double-toothed roller crusher and combined with the material under the sieve, and then enters a desliming sieve with a sieve hole of 0.5mm. The material on the mud sieve enters the vertical wheel heavy-medium separator, and the clean coal I, medium coal I and gangue I are sorted out, and the clean coal I is transported to the clean coal bunker, and the gangue I is transported to the gangue hill;

[0025] (2) Midcoal Ⅰ enters a sieve with a sieve hole of 50mm. The material on the sieve is crushed by a jaw crusher and combined with the material under the sieve for ultra-fin...

Embodiment 2

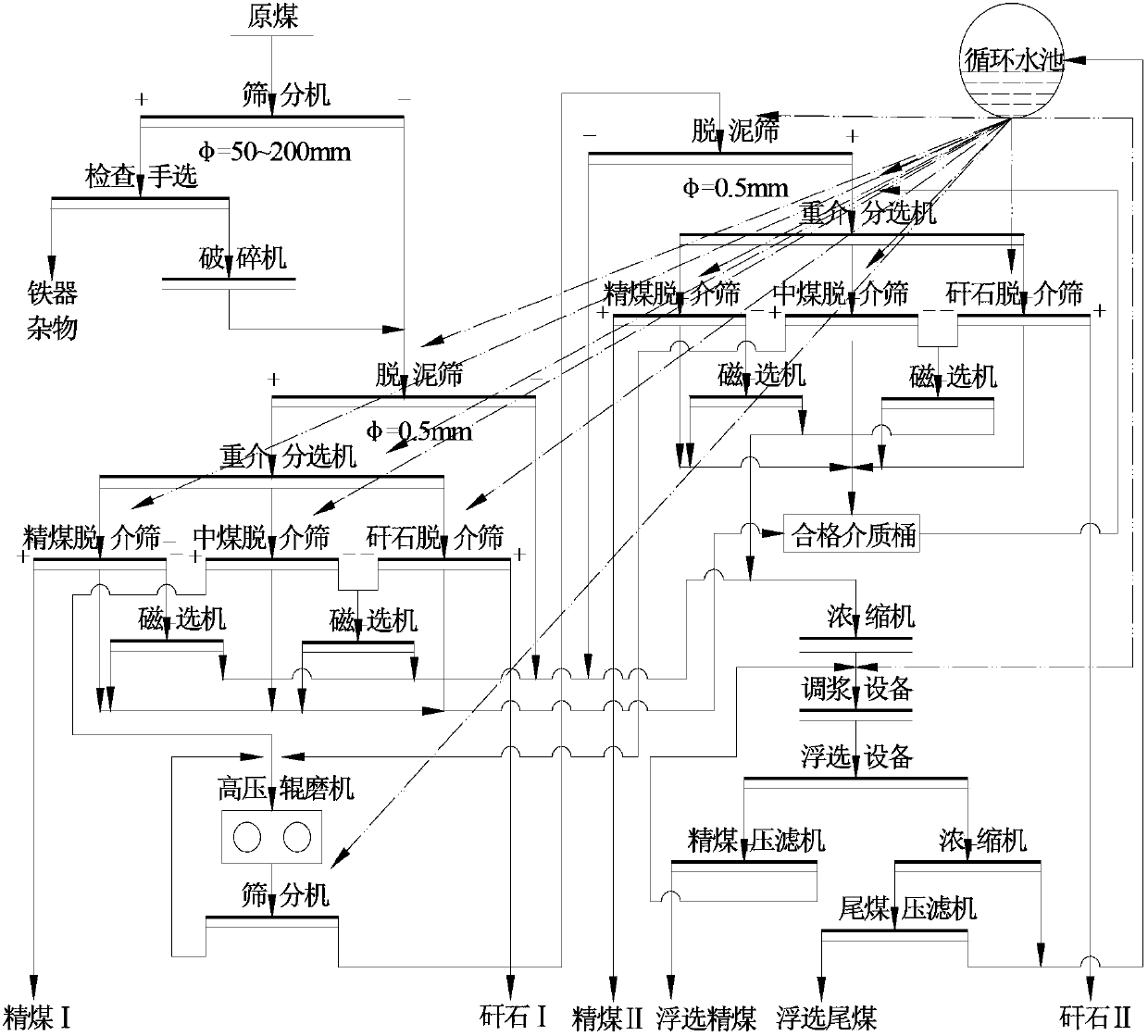

[0029] The raw coal is coking coal with an ash content of 39.75%. The coal washing plant is a group-type central coal washing plant with a processing capacity of 5 million t / a. The high-pressure roller mill is used to carry out ultra-fine crushing of medium coal and then sorting. The process steps are as follows:

[0030] (1) Raw coal enters a sieve with a sieve hole of 50mm. The material on the sieve is crushed by a double-toothed roller crusher and combined with the material under the sieve, and then enters a desliming sieve with a sieve hole of 0.5mm. The material on the mud screen enters the three-product dense medium cyclone, and the clean coal I, medium coal I and gangue I are sorted out, the clean coal I is transported to the clean coal bin, and the gangue I is transported to the gangue hill;

[0031] (2) China Coal I carries out high-pressure roller mill ultra-fine crushing, the pressure between the rollers is 4.0MPa, the roller speed is 2.0m / min, and the roller gap is...

Embodiment 3

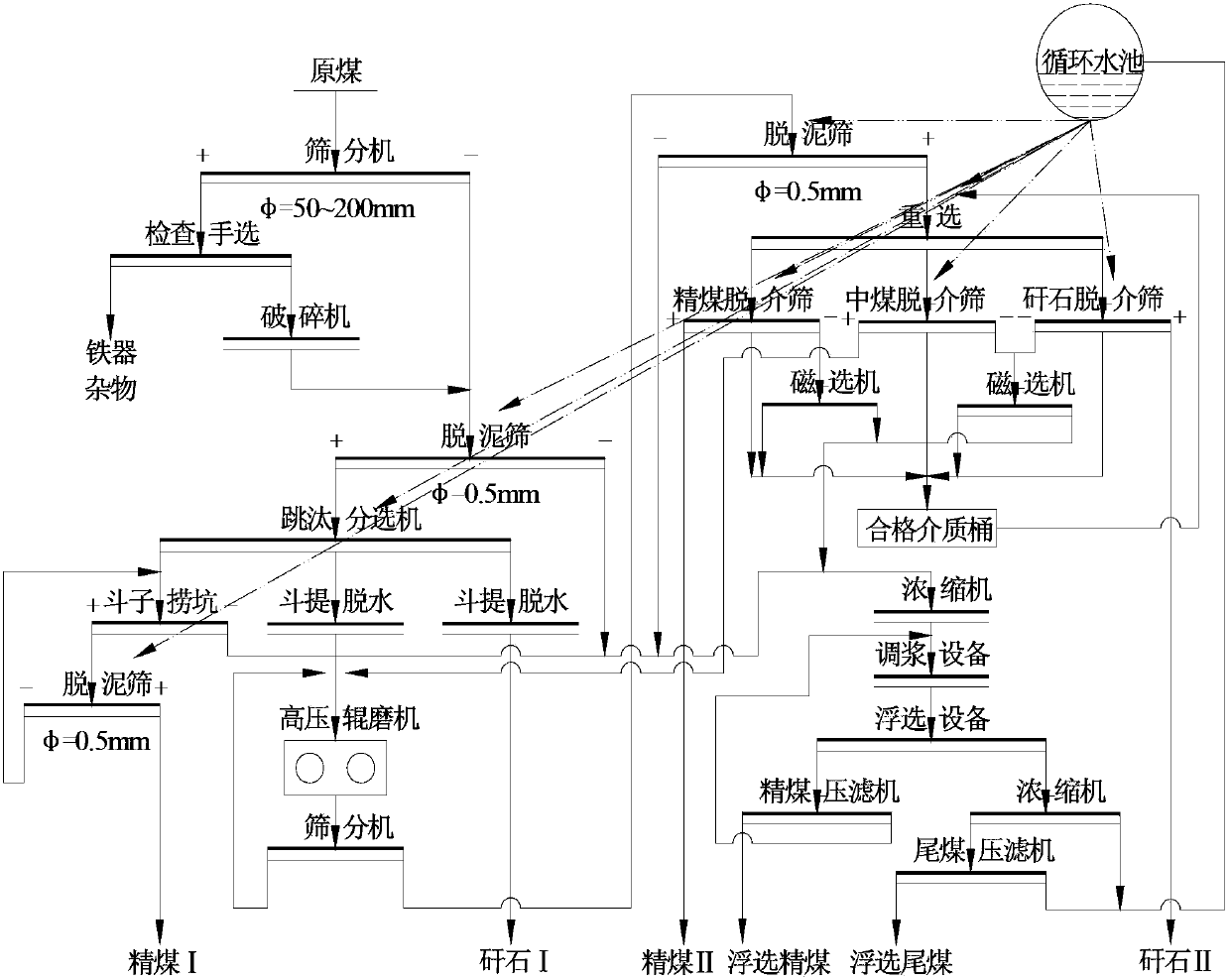

[0035] The raw coal is coking coal with an ash content of 19.40%. The coal washing plant is a mine-type coal washing plant with a processing capacity of 3 million t / a. The high-pressure roller mill is used to carry out ultra-fine crushing of medium coal and then sorting. The process steps are as follows:

[0036] (1) Raw coal enters a sieve with a sieve hole of 50 mm. The material on the screen is crushed by a double-toothed roller crusher and combined with the material under the screen to enter the jig separator to separate clean coal I, medium coal I and gangue Ⅰ, clean coal Ⅰ is transported to the clean coal bunker, and gangue Ⅰ is transported to the gangue hill;

[0037] (2) China Coal I carries out high-pressure roller mill ultra-fine crushing, the pressure between the rollers is 6.0MPa, the roller speed is 1.0m / min, and the roller gap is 13mm; the crushed material enters the sieve with a sieve hole of 13mm, and the material on the sieve Combined with the high-pressure rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com