Raw coal sorting process

A sorting and raw coal technology, applied in wet separation, solid separation, water/sludge/sewage treatment, etc., can solve the problems of high operating cost, large slime content, large investment, etc., and achieve low investment and operating costs , simplify facilities and equipment, and reduce the effect of slime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

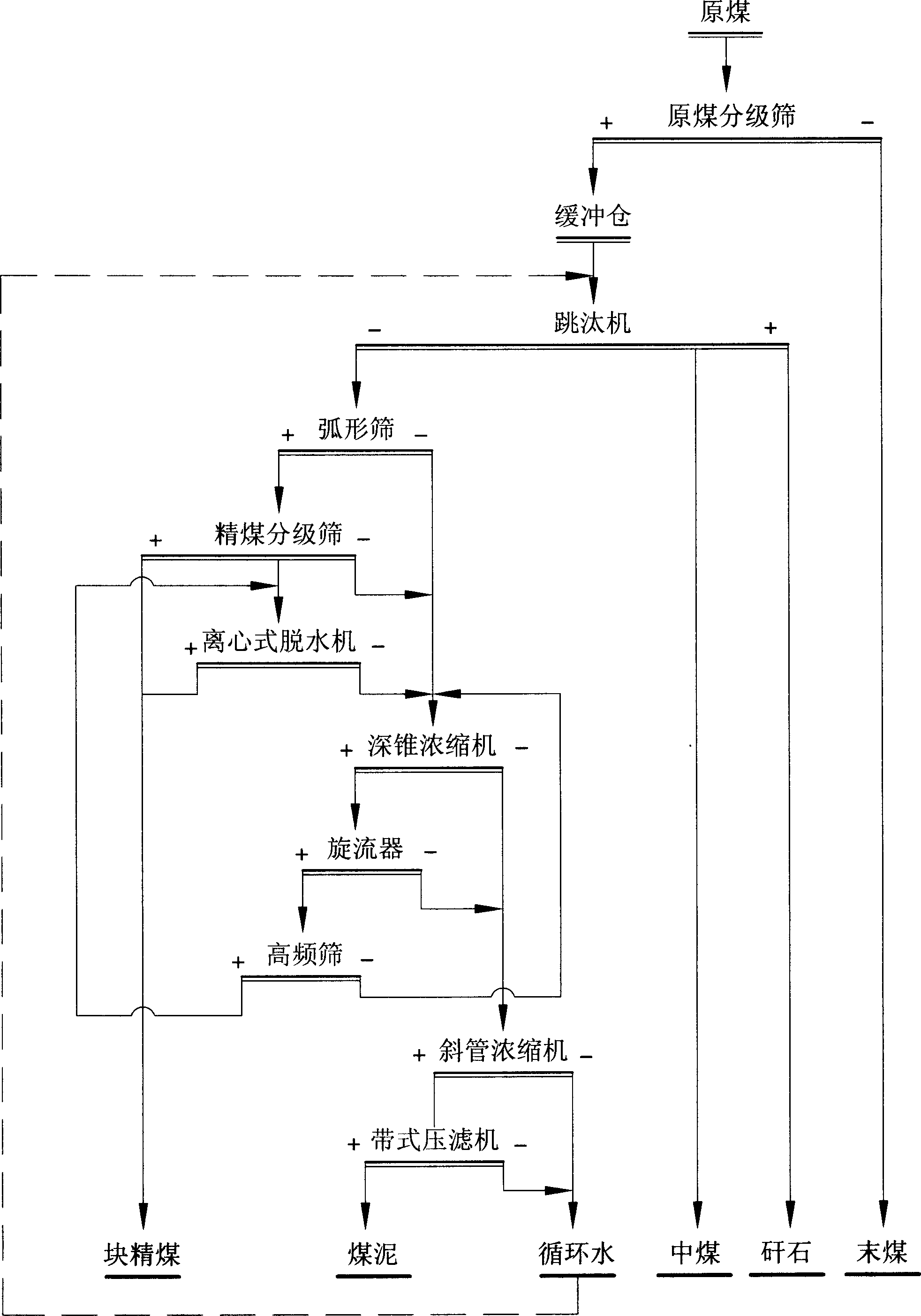

[0024] Such as figure 1 As shown, the raw coal is first classified through a raw coal grading sieve with a sieve size of 13mm, and the undersize (coal with a particle size of less than 13mm) is transported to the final coal product warehouse by a belt conveyor; the oversize (with a particle size between 13mm and 50mm) Coal) enters the buffer bin before the jig (the buffer bin is used to improve the uniformity and continuity of the amount of raw coal entering the jig to ensure the separation effect of the jig), and then enters the jig through the coal feeder Washing is carried out, and three products are separated by jig machine: heavy product gangue, intermediate coal, and light product block clean coal. The heavy product gangue is dehydrated by the bucket elevator and belt conveyor, and is exported to the ground for sale or transported to the gangu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com