Coarse slime separation process

A coarse slime and sorting technology, which is used in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of decreased sorting effect, serious economic loss of enterprises, serious medium loss, etc. Perfect, low cost of technical transformation, reducing the effect of medium consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

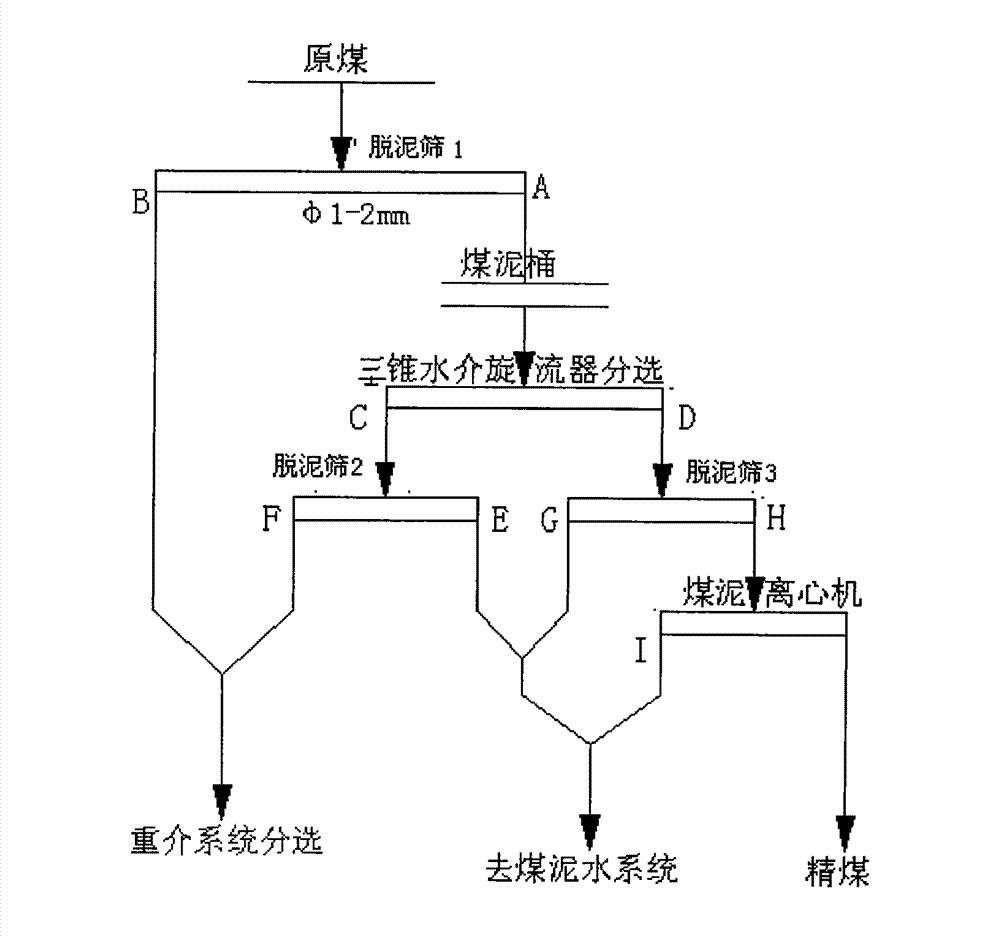

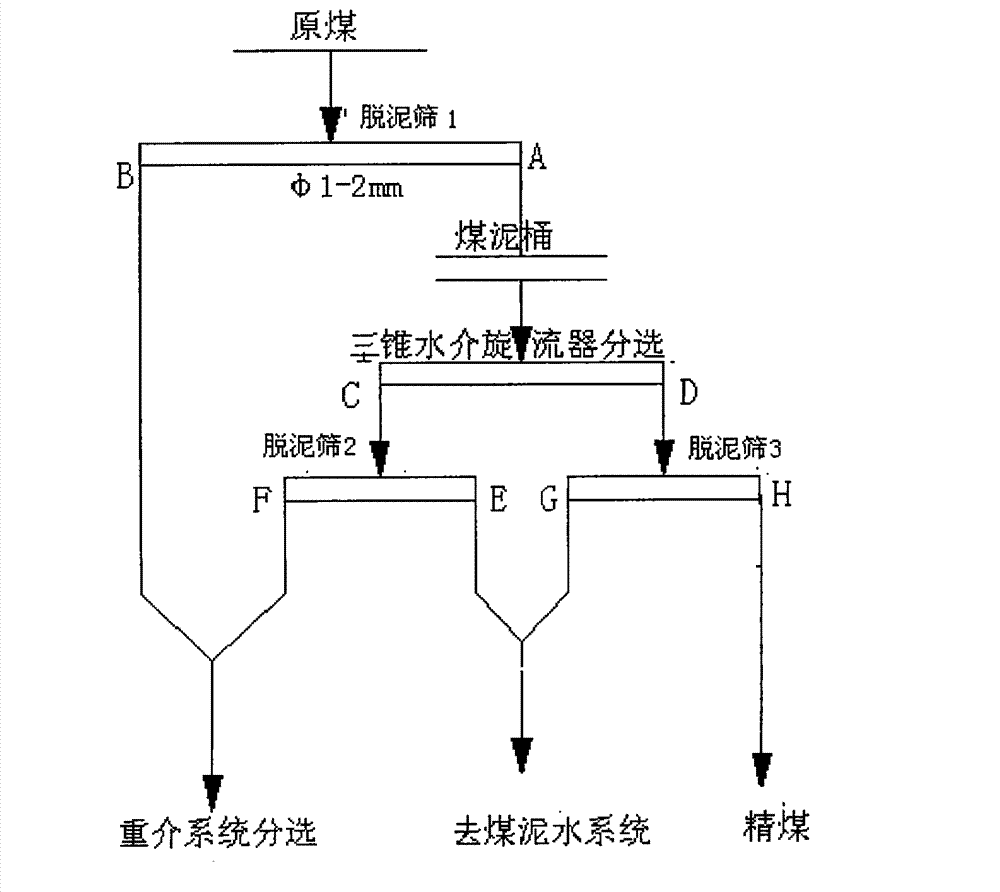

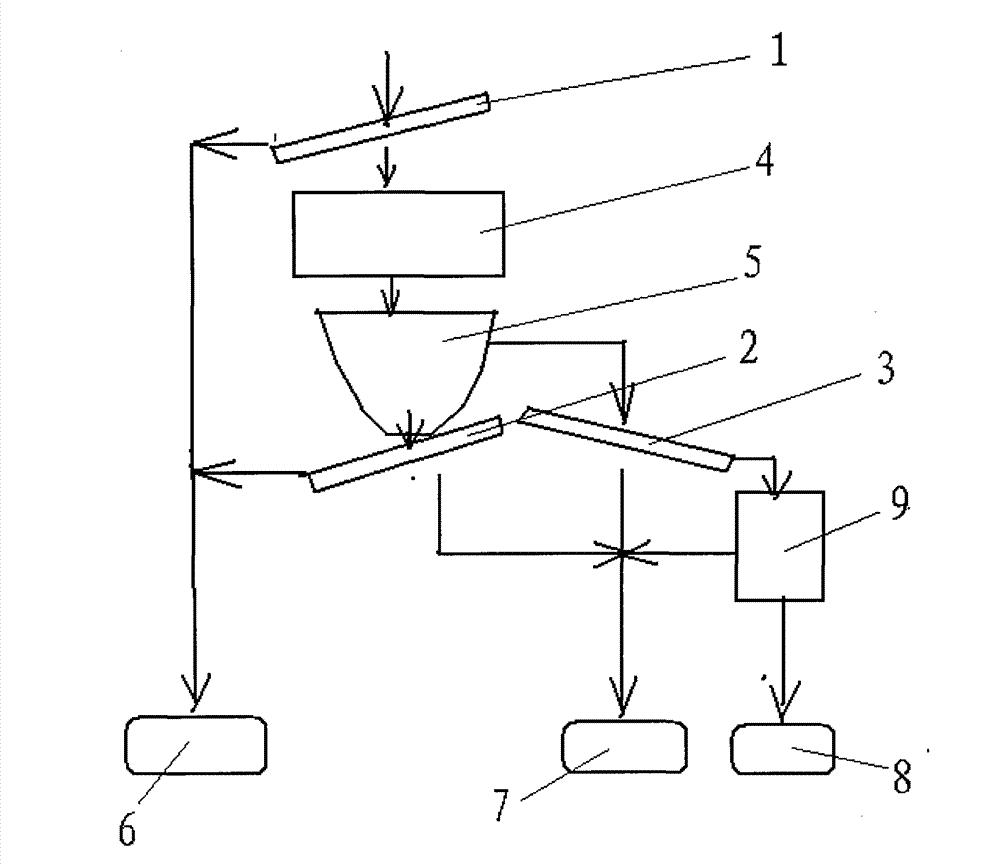

[0040] The sorting process of the present invention will be described below in conjunction with the accompanying drawings.

[0041] Such as figure 1 and image 3 As shown, the detailed process of Embodiment 1 of the present invention is as follows:

[0042] first step:

[0043] The raw coal first enters the first desliming screen 1 to obtain the first undersize A and the first oversize B;

[0044] Step two:

[0045] The first sieve material A enters the coal slime bucket 4, and is directly pumped into the triangular-angle hydrocyclone 5 for sorting to obtain the underflow C and overflow D of the tri-cone hydrocyclone;

[0046] third step:

[0047] The bottom flow C of the tri-cone hydrocyclone enters the second desliming screen 2 for desliming to obtain the second undersize E and the second oversize F;

[0048] The overflow D of the tri-cone hydrocyclone enters the third desliming screen 3 for desliming to obtain the third undersize G and the third oversize H;

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com