Coal blending method for producing high-quality coke by high-proportion matched use of lean coal and gas coal

A technology with a large proportion of lean coal, which is applied in coking ovens and the petroleum industry, can solve the problems of not being able to mix more lean coal, the cost of coal blending can not be greatly reduced, and the problem of not being able to mix more gas coal, so as to reduce the cost of iron and reduce the cost of blending Coal cost and blast furnace coke cost, and the effect of reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

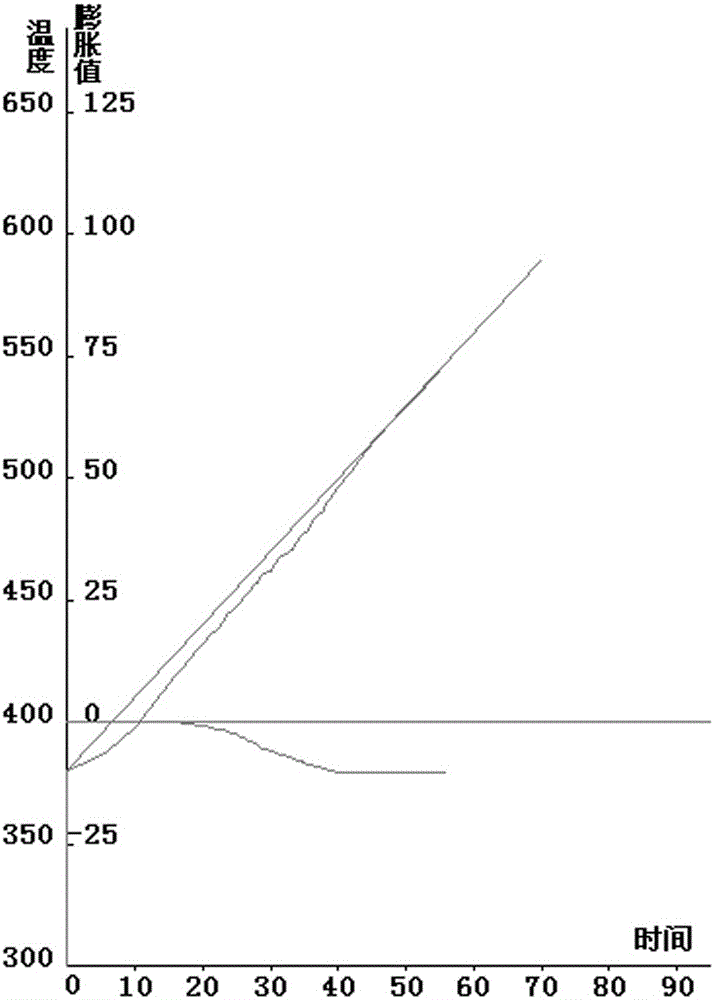

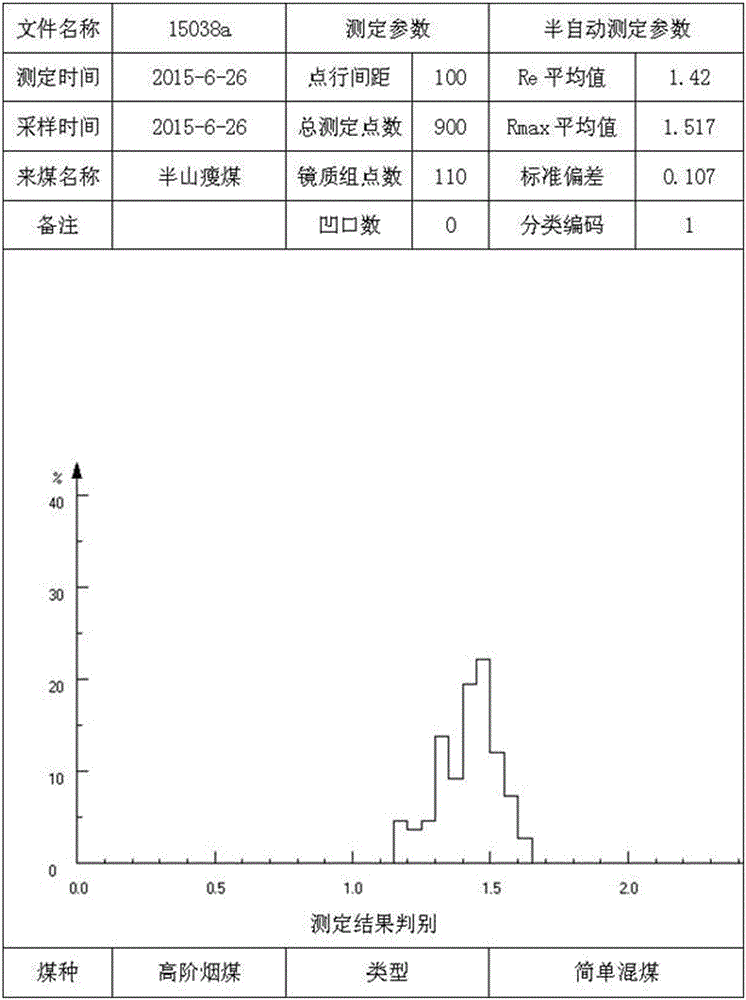

Image

Examples

Embodiment 1

[0047] coal name

[0048] The ratio of coking coal is shown in Table 4

[0049]

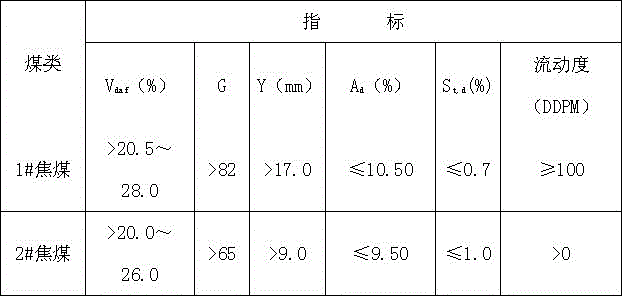

[0050] V daf ,%

[0051] indicators

[0052] Furnace capacity, m 3

Embodiment 2

[0054] coal name

[0055] The coking coal ratio is shown in Table 9

[0056]

[0057] V daf ,%

[0058] indicators

[0059] Furnace capacity, m 3

Embodiment 3

[0061] coal name

[0062] See Table 14 for the ratio of coking coal

[0063]

[0064] V daf ,%

[0065] indicators

[0066] Furnace capacity, m 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com