Method for plasticizing lower-grade metamorphic bituminous

A low metamorphism, bituminous coal technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of no obvious enhancement of coal plasticity, high pressure and temperature, and achieve the effects of enhanced cohesion, easy operation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

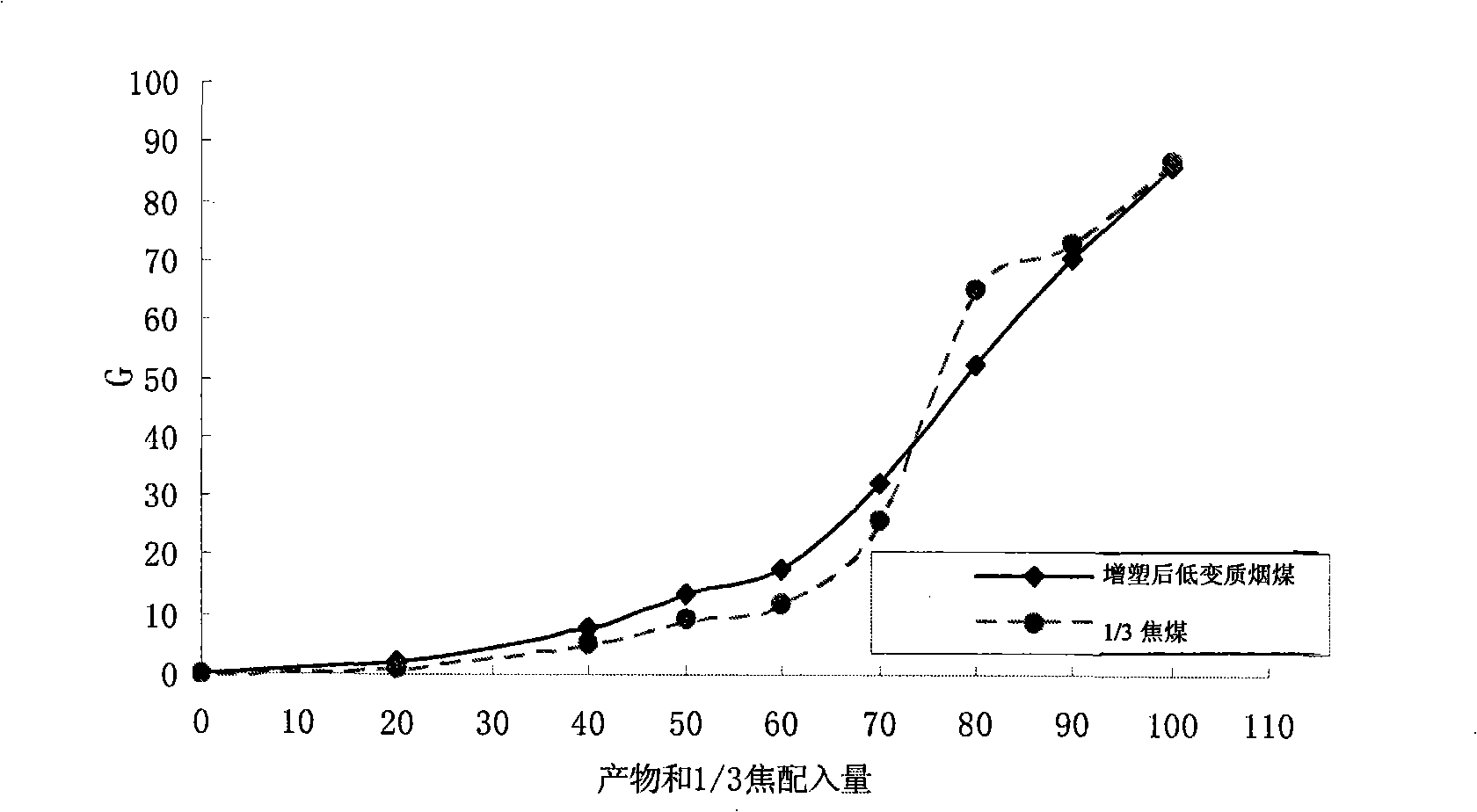

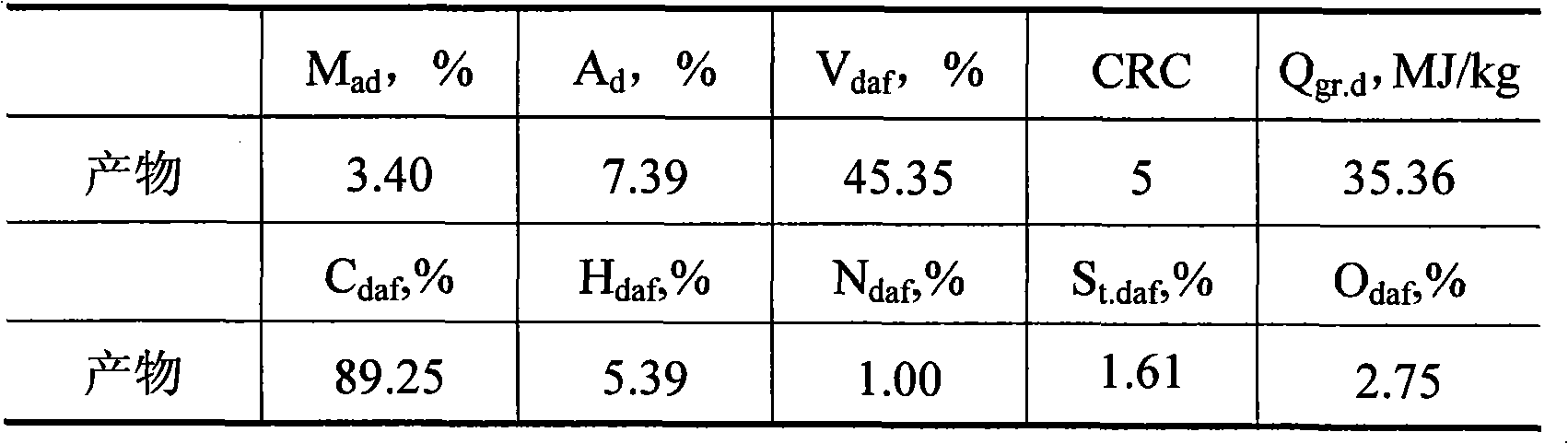

[0013] Embodiment 1, plasticized low metamorphic bituminous coal

[0014] 1. Preparation of Plasticized Low Metamorphic Bituminous Coal

[0015] Put the low metamorphic bituminous coal (raw coal) and the hydrogenation solvent tetrahydronaphthalene in a high-pressure reactor (the effective volume of the high-pressure reactor is about 1000ml, the design pressure is about 20MPa, and the design temperature is 500°C) and mix evenly, and hydrogen is introduced to make The hydrogen pressure in the reaction kettle is 4.0Mpa. Under the action of catalyst ferric oxide and cocatalyst sulfur, after reacting at a constant temperature of 350°C for 50 minutes, cool down the reaction kettle, and dry the product at 105°C with an electric heating constant temperature blast drying oven. The plasticized low-modified bituminous coal is obtained. Among them, the amount of solvent tetrahydronaphthalene is 2.5 times the mass of the raw coal, the amount of ferric oxide is 3% of the mass of the raw co...

Embodiment 2

[0027] Embodiment 2, plasticized low metamorphic bituminous coal

[0028] Put raw coal and hydrogenation solvent tetrahydronaphthalene in a high-pressure reaction kettle and mix them evenly, and feed hydrogen gas to make the hydrogen pressure in the reaction kettle 3.0Mpa. After reacting at a constant temperature of ℃ for 30 minutes, the reaction kettle was cooled, and the product was dried at 105 ℃ with an electric heating constant temperature blast drying oven to obtain plasticized low-deterioration bituminous coal. Wherein, the amount of solvent tetrahydronaphthalene is twice the mass of the raw coal, the amount of ferric oxide is 3% of the mass of the raw coal, and the amount of the promoter is 1% of the mass of the raw coal.

[0029] The plasticized low-metamorphic bituminous coal is tested, and it can be known that the average maximum reflectance of the vitrinite of the low-metamorphic bituminous coal R° max At about 0.85%, the caking index is 90, and the conversion rat...

Embodiment 3

[0030] Embodiment 3, plasticized low metamorphic bituminous coal

[0031] Put raw coal and hydrogenation solvent tetrahydronaphthalene in a high-pressure reaction kettle and mix them evenly, and feed hydrogen to make the hydrogen pressure in the reaction kettle 6.0Mpa. After reacting at a constant temperature of ℃ for 50 minutes, the reaction kettle was cooled, and the product was dried at 105 ℃ with an electric heating constant temperature blast drying oven to obtain plasticized low-deterioration bituminous coal. Among them, the amount of solvent tetrahydronaphthalene is 2.5 times the mass of the raw coal, the amount of ferric oxide is 3% of the mass of the raw coal, and the amount of the promoter is 1% of the mass of the raw coal.

[0032] The plasticized low-metamorphic bituminous coal is tested, and it can be known that the average maximum reflectance of the vitrinite of the low-metamorphic bituminous coal R° max At about 0.69%, the caking index is 77, and the conversion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com