Predicating method for abrasive resistance of coal-blending coking coke

A technology of wear resistance and prediction method, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of large test workload, long cycle, not taking into account the optical structure of coke formation, etc., and achieves simple prediction formula and good fit. High and shorten the effect of coal blending cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

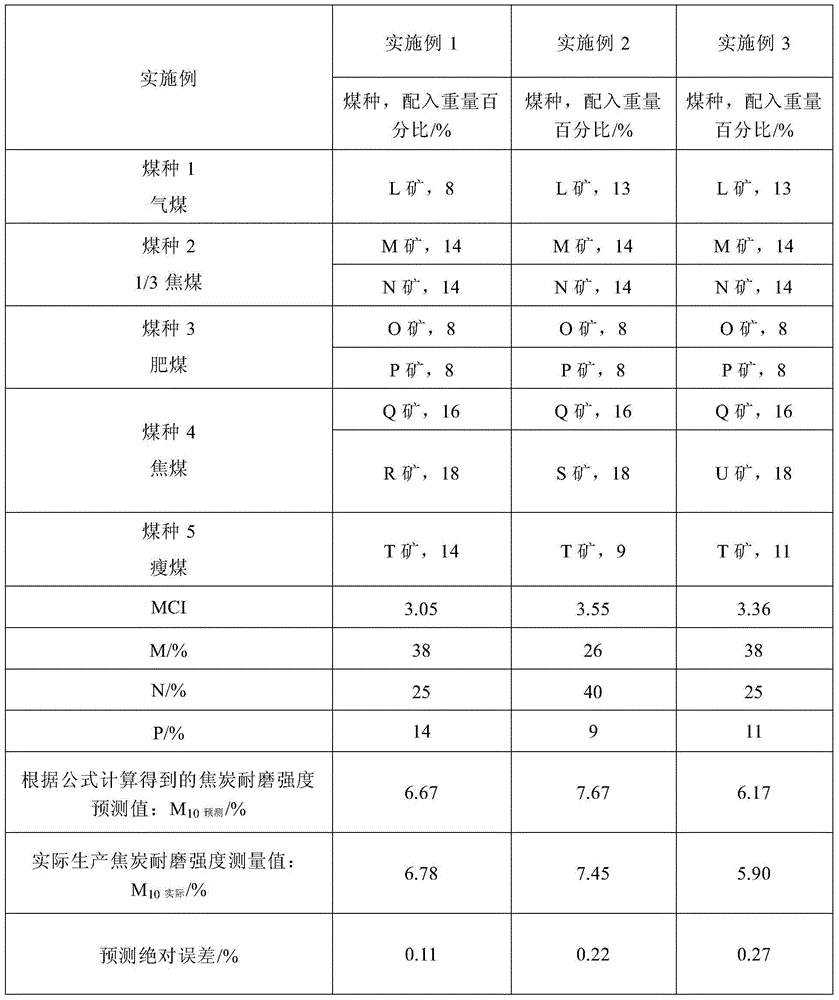

[0018] The present invention will be described in further detail below in conjunction with specific embodiments.

[0019] Method of the present invention comprises the steps:

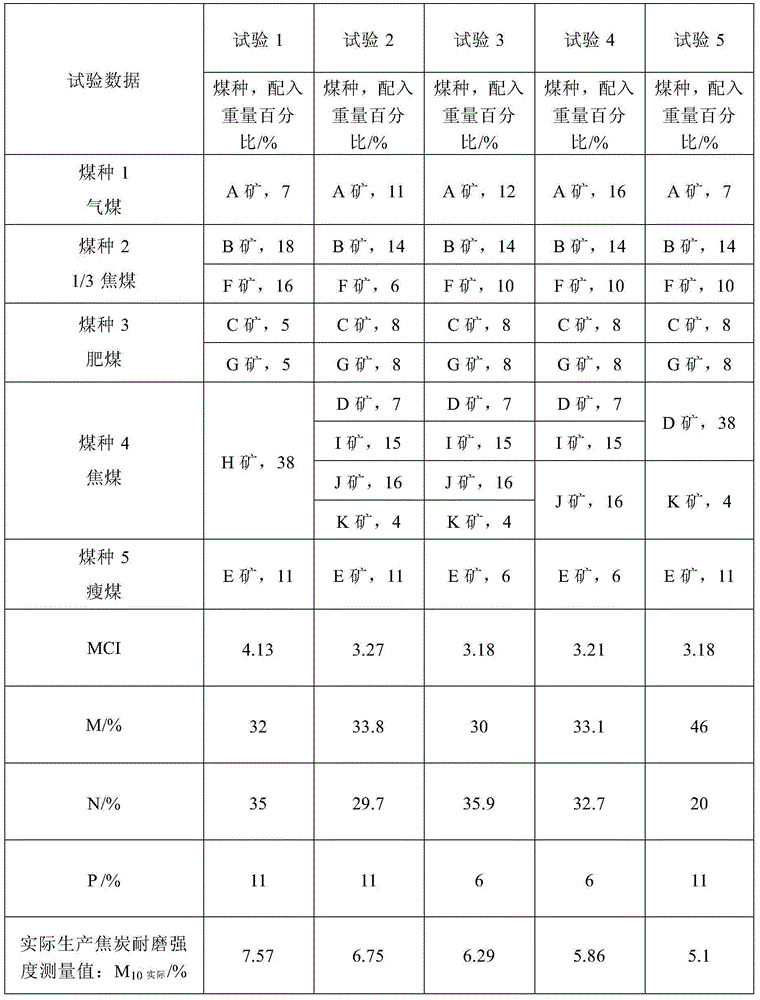

[0020] 1) Measure the components of each single coal ash used in coking, and calculate the mixed coal mineral index MCI;

[0021] 2) Determine the coke-forming optical structure of each single coal used for coking, and calculate the sum M of the coarse-grained mosaic, medium-grained mosaic, and incomplete fiber components in the blended coal, the isotropic component and the fine-grained The sum N of mosaic component content;

[0022] 3) Measure the average maximum reflectance of vitrinite of each single coal used for coking, and obtain the reflectance of blended coal through statistics The blending ratio P of lean coal;

[0023] 4) Set M 10 =A+B*MCI+C*M+E*N+F*P, where M 10 Represents the wear resistance of coke, the unit is %; A, B, C, E, F are constants, which can be calculated by substituting fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com