Method for preparing coking coal by modification by low-order nonadhesive coal

A technology of non-caking coal and coking coal, which is applied in coking ovens, preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems that the effect is not obvious, has no industrial value, and the process stays in the batch test, etc. Achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

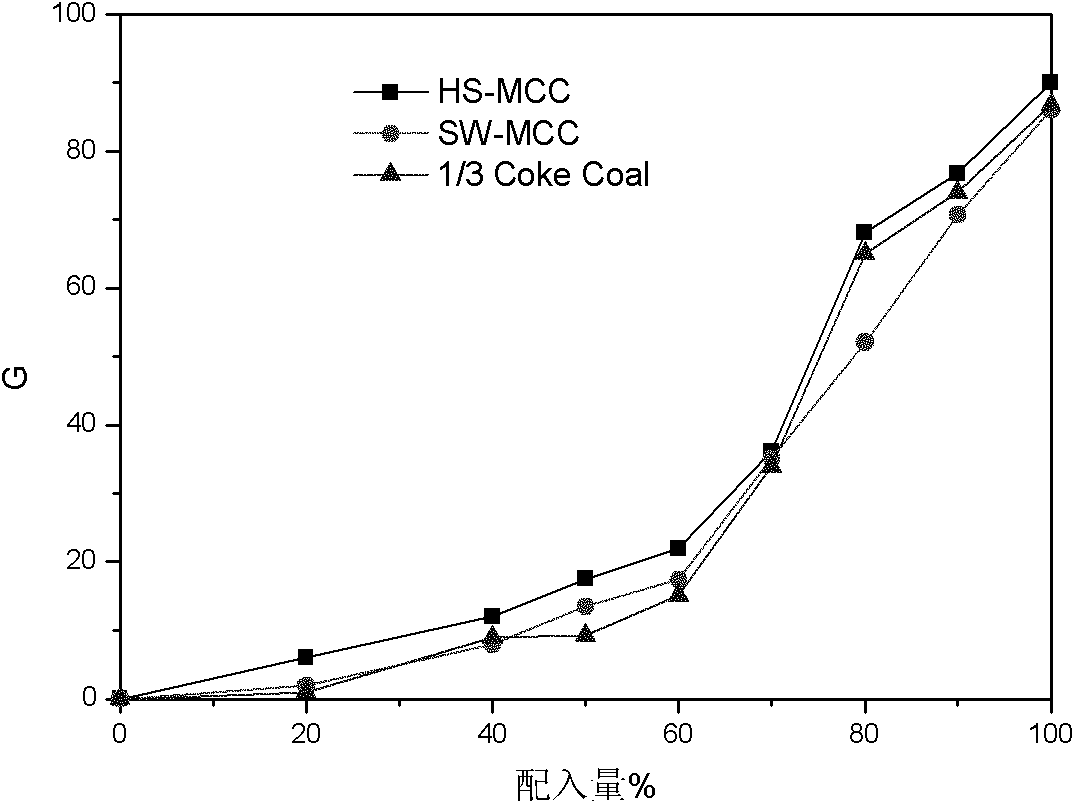

[0040] The solid product that the present invention obtains is called upgrading coking coal Example 1, two kinds of bituminous coal blended with HTA upgrading to make coking coal

[0041] 1. Preparation of upgraded coking coal products

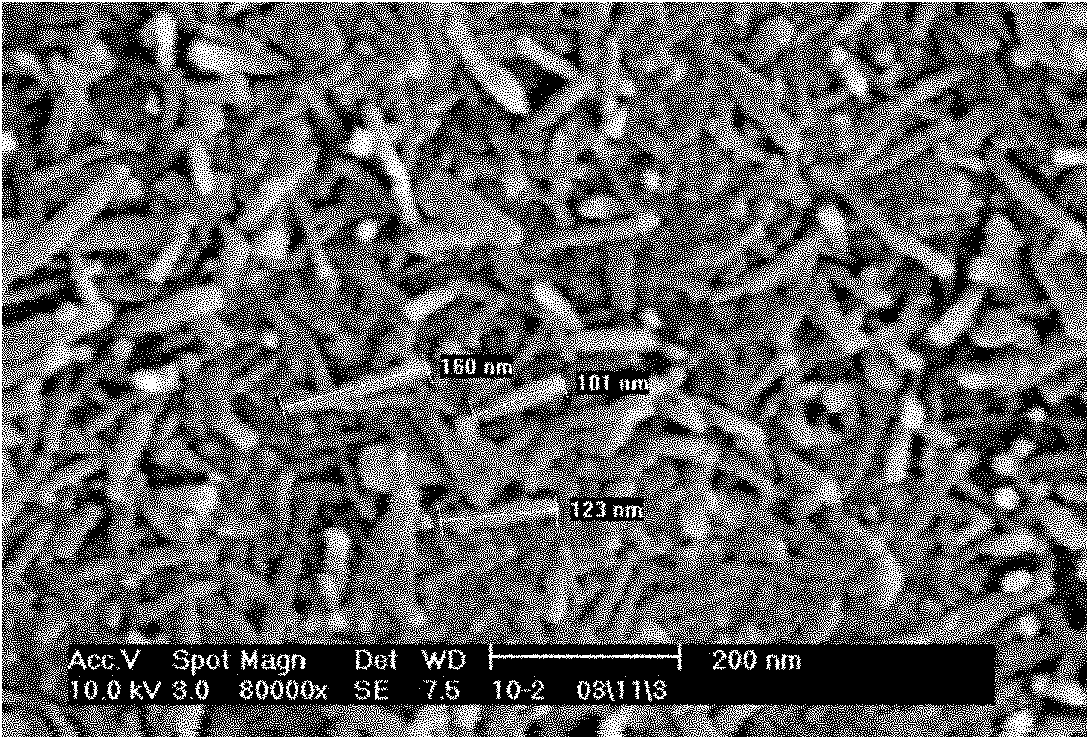

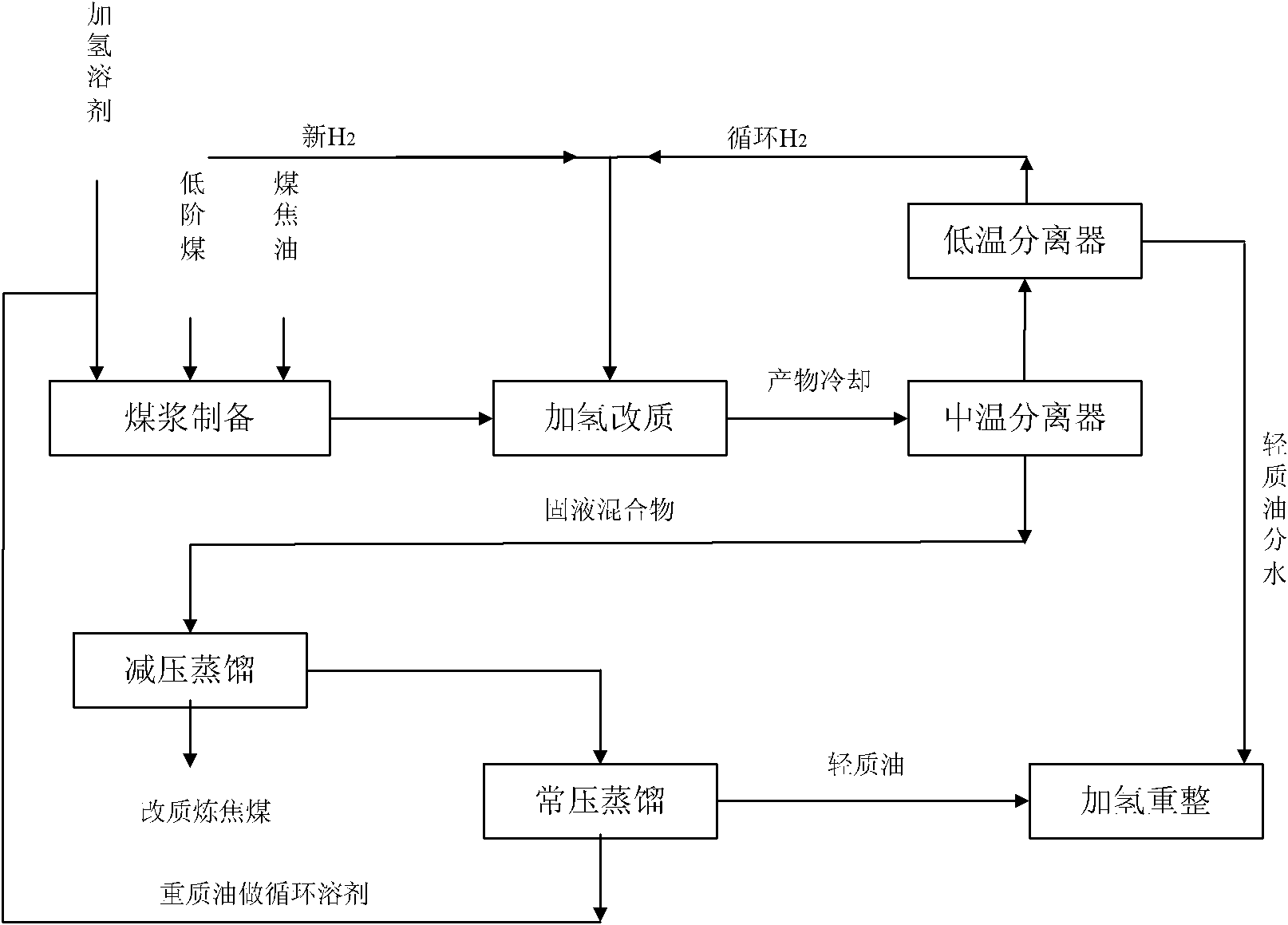

[0042] Xinjiang Heishan coal and Inner Mongolia Shangwan coal were used as raw materials, both of which had no caking property (G=0). Heishan coal has the characteristics of high vitrinite and low inertinite content, and Shangwan coal has slightly higher inertinite content. HTA is obtained from a domestic coking plant tar after distillation. The industrial analysis and elemental analysis data of two kinds of bituminous coal and HTA are in Table 1, the initial hydrogenation solvent is a solvent prepared by catalytic hydrogenation process with a distillation range of 220-540° C. and a fa>60% petroleum fraction as a raw material. The properties of the hydrogenated solvent are shown in Table 2. The reaction temperature is 390° C., the hydrogen in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com