Method for preparing polyaniline surface modified conductive polyester chips

A technology of surface modification and polyester sheet, applied in the field of preparation of conductive polyester sheet, can solve problems such as weak intermolecular force, and achieve the effects of increasing surface area, increasing polar groups, and enhancing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

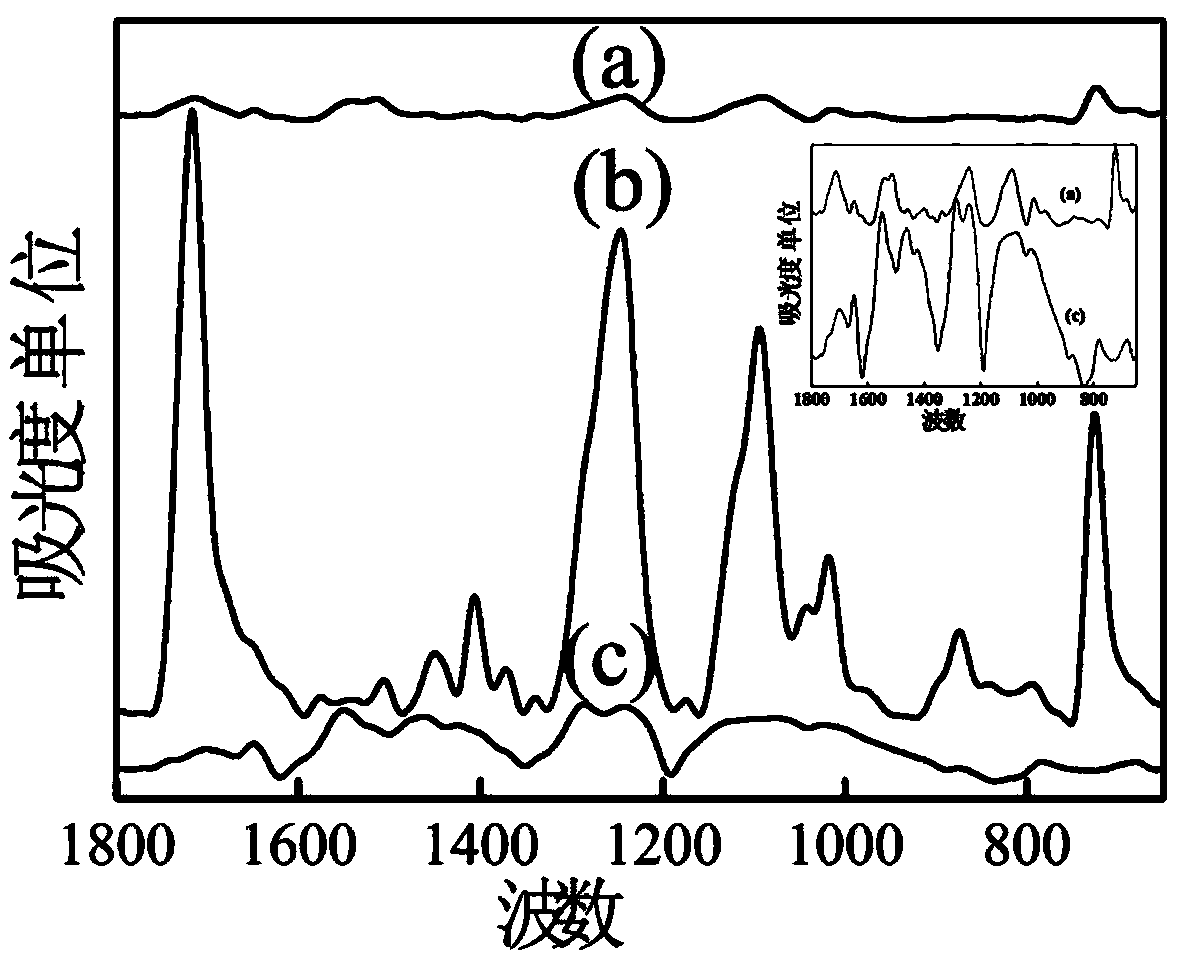

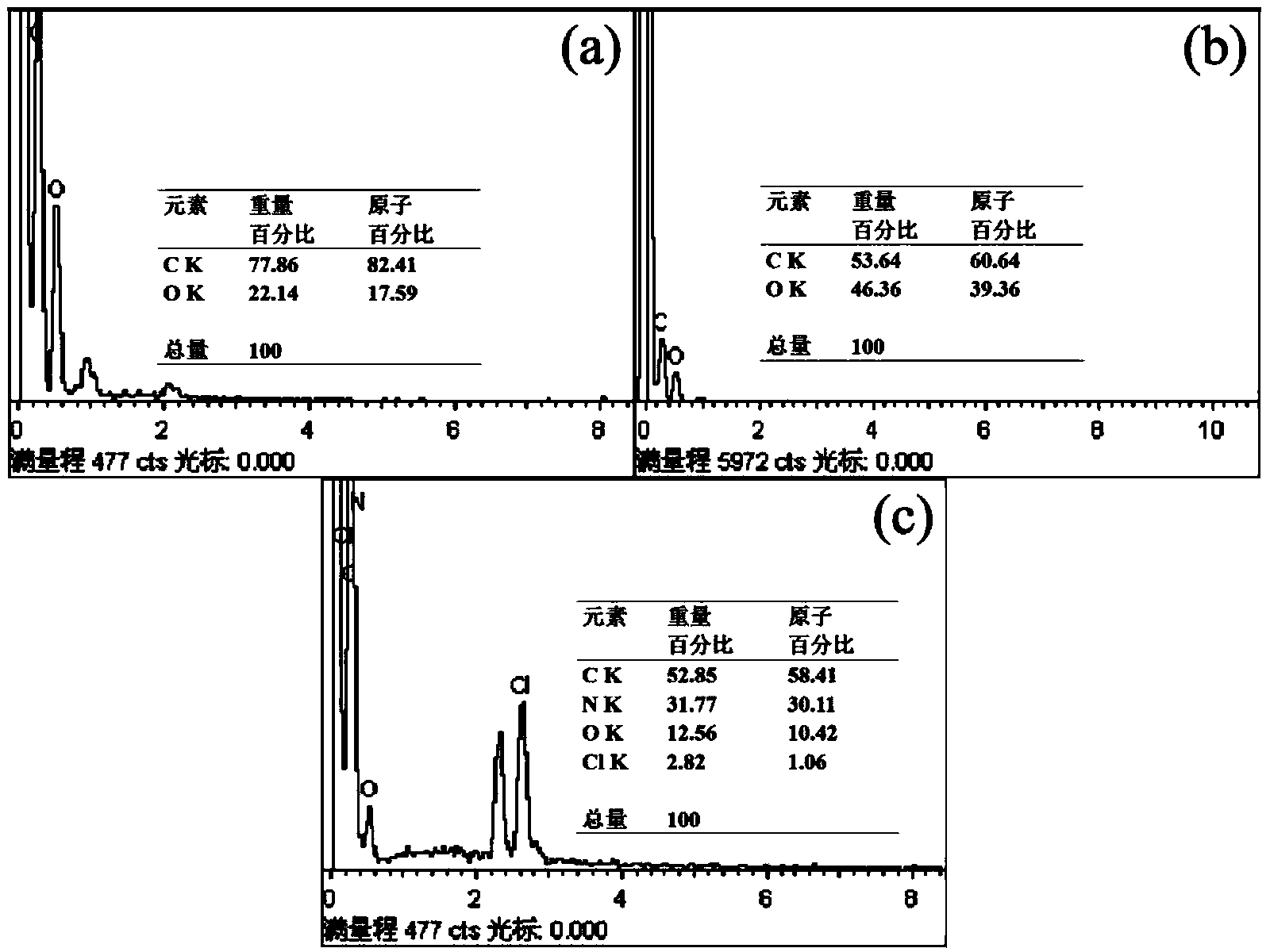

Method used

Image

Examples

Embodiment 1

[0024] (1) Deoil the polyester sheet with acetone, dry it and hydrolyze it in concentrated sulfuric acid solution (volume ratio of sulfuric acid to water: 4:1) for 2 minutes.

[0025] (2) Add the polyester flakes (60mg) obtained in step (1), 6g of aniline and 60mL of 3M hydrochloric acid solution into the four-necked flask in turn, and start the mechanical stirring to mix them thoroughly; after the temperature is lowered to 0-5°C, Slowly add 50 mL of ammonium persulfate (0.25:1 molar ratio to aniline) aqueous solution dropwise with a dropping funnel, and the dropwise addition is completed in 30 minutes; the reaction ends after 5 hours.

[0026] (3) Wash the polyester sheet prepared in step (2) with 0.1 mol / L hydrochloric acid and a large amount of water, and dry at room temperature.

[0027] The electrical conductivity of the prepared polyester sheet modified by polyaniline was 3.34×10 -3 S / cm.

Embodiment 2

[0029] (1) Deoil the polyester sheet with acetone, dry it and hydrolyze it in concentrated sulfuric acid solution (volume ratio of sulfuric acid to water: 4:1) for 2 minutes.

[0030] (2) Add the polyester flakes (60mg) obtained in step (1), 6g of aniline and 60mL of 2M hydrochloric acid solution into the four-neck flask in turn, and start the mechanical stirring to make them fully mixed; after the temperature drops to 0-5°C, Slowly add 50 mL of ammonium persulfate (0.5:1 molar ratio to aniline) aqueous solution dropwise with a dropping funnel, and the dropwise addition is completed in 30 minutes; the reaction ends after 5 hours.

[0031] (3) Wash the polyester sheet prepared in step (2) with 0.1 mol / L hydrochloric acid and a large amount of water, and dry at room temperature.

[0032] The electrical conductivity of the prepared polyester sheet modified by polyaniline was 3.33×10 -3 S / cm.

Embodiment 3

[0034] (1) Deoil the polyester sheet with acetone, dry it and hydrolyze it in concentrated sulfuric acid solution (volume ratio of sulfuric acid to water: 5:1) for 1 min.

[0035] (2) Add the polyester flakes (60mg) obtained in step (1), 6g of aniline and 60mL of 3M hydrochloric acid solution into the four-necked flask in turn, and start the mechanical stirring to make them fully mixed; after the temperature drops to 0-5°C, Slowly add 50 mL of ammonium persulfate (0.5:1 molar ratio to aniline) aqueous solution dropwise with a dropping funnel, and the dropwise addition is completed in 30 minutes; the reaction ends after 5 hours.

[0036] (3) Wash the polyester sheet prepared in step (2) with 0.1 mol / L hydrochloric acid and a large amount of water, and dry at room temperature.

[0037] The electrical conductivity of the prepared polyester sheet modified by polyaniline was 3.93×10 -3 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com