Method for preparing active carbon with high specific surface area from coal and waste and old plastics by microwave

A technology of waste plastic and high specific surface area, applied in the field of chemical industry activated carbon preparation, to achieve the effect of high specific surface area, shortening carbonization time and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

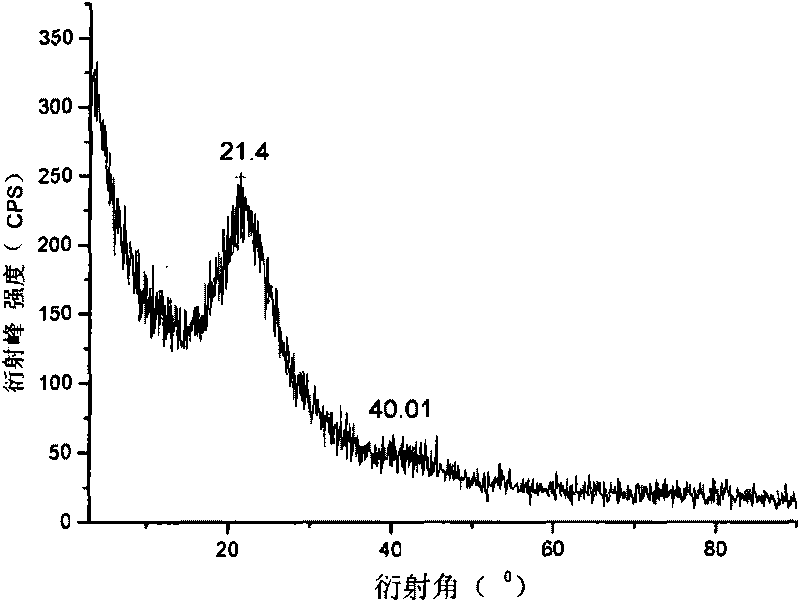

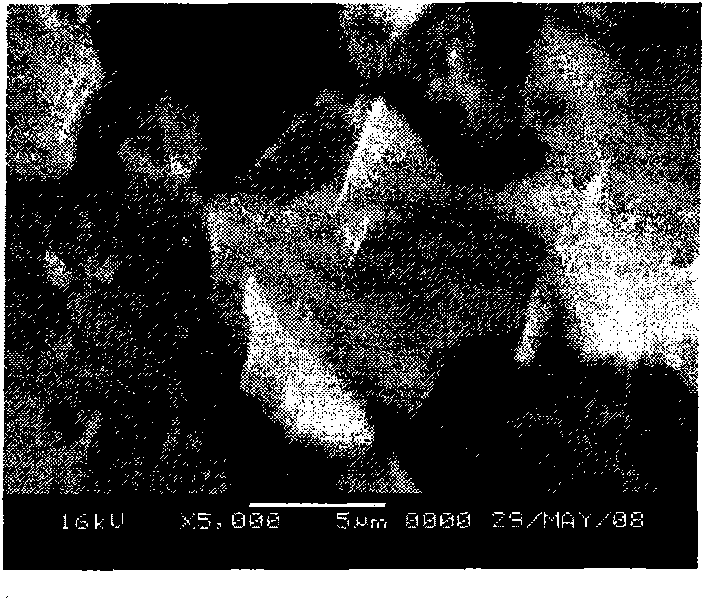

Image

Examples

Embodiment 1

[0018] The silk charcoal component is manually stripped from the raw coal, and the stripped silk charcoal is crushed to about 0.05mm. Crush waste beverage bottles to about 0.5mm. Take 0.600g of silk charcoal powder, add 0.400g of waste beverage bottle powder and 3.000g of KOH activator, mix evenly, put it into a microwave oven (frequency 2450MHz), preheat it under the radiation of small microwave power (250W) for 1min, and then use Required power (450W) carbonization activation 5.5min. After the carbonized material is cooled, take it out, pour it into a container filled with dilute hydrochloric acid for washing, let it stand for 10 minutes, filter it, and wash it with distilled water until neutral. Activated carbon with high specific surface area can be obtained after drying and crushing. The prepared activated carbon has an iodine adsorption value of 1837 mg / g and a methylene blue adsorption value of 833.2 mg / g.

Embodiment 2

[0020] Crush the raw coal to about 0.05mm, put it in an oven, and oxidize it in air at 80-100°C for 5 days. Crush waste beverage bottles to about 0.5mm. Take 0.800g of oxidized coal powder, add 0.200g of waste beverage bottle powder and 3.000g of KOH activator, mix well, put it into a microwave oven (frequency 2450MHz), and carbonize and activate at power (450W) for 6.5min. After the carbonized material is cooled, take it out, pour it into a container filled with dilute hydrochloric acid for washing, let it stand for 10 minutes, filter it, and wash it with distilled water until neutral. Activated carbon with high specific surface area can be obtained after drying and crushing. The prepared activated carbon has an iodine adsorption value of 1664 mg / g and a methylene blue adsorption value of 814.9 mg / g.

Embodiment 3

[0022] Crush the raw coal to about 0.05mm, put it in an oven, and oxidize it in air at 80-100°C for 7 days. Crush waste beverage bottles to about 0.5mm. Take 0.600g of oxidized coal powder, add 0.400g of waste beverage bottle powder and 3.000g of KOH activator, mix well, put it into a microwave oven (frequency 2450MHz), and carbonize and activate at power (450W) for 6.5min. After the carbonized material is cooled, take it out, pour it into a container filled with dilute hydrochloric acid for washing, let it stand for 10 minutes, filter it, and wash it with distilled water until neutral. Activated carbon with high specific surface area can be obtained after drying and crushing. The prepared activated carbon has an iodine adsorption value of 1611 mg / g and a methylene blue adsorption value of 808.5 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com