A method for blending high volatile coking coal

A high-volatility, coking coal technology, applied in the coking oven, petroleum industry, etc., can solve the problems of coke cold strength and thermal performance, coke coking rate reduction, increase the amount of gas generation, etc., to improve coke quality and chemical products The effect of increasing yield and avoiding severe decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

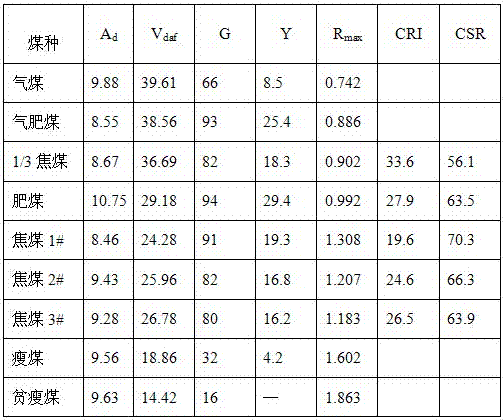

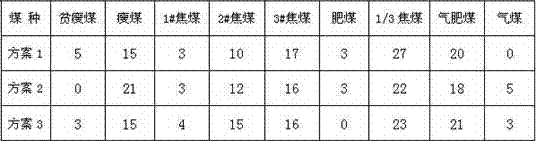

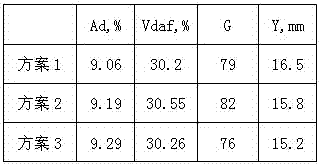

[0012] The present invention is a method for blending coking coal with high volatile content. The blending ratio of each single coking coal is as follows: 0-5% gas coal, 15%-23% gas-fat coal, 0-8% fat coal, 1 / 3 coking coal 19-28%, coking coal 30%-48%, lean coal 8-25%, lean coal 0-7%. Coking coal includes coking coal 1#, coking coal 2# and coking coal 3# with a volatile content of 22% to 27%, and their weight percentages are 0 to 6% for coking coal 1# and 10% to 19% for coking coal 2#, respectively. Coking coal 3# is 16% to 25%, and the sum of their weight percentages is 30% to 48%; the coking index of coking coal 1# is G≥85, and the average maximum reflectance Rmax of vitrinite is 1.256 to 1.415, 40Kg small coke oven test thermal reactivity CRI≤20%, post-reaction strength CSR≥70%; coking coal 2# cohesion index G value: 80≤G<85, vitrinite average maximum reflectance Rmax is 1.159~1.268 , 40Kg small coke oven experiment thermal reactivity CRI≤25%, post-reaction strength CSR≥65%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion index | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com