Method for producing high-quality metallurgical coke by using coal and rock indexes

A metallurgical coke, high-quality technology, applied in coke ovens, petroleum industry and other directions, can solve the problems of high proportion of fat coal and coking coal, difficulty in ensuring the quality of metallurgical coke, different degrees of coal mixing, etc. Reduced resource consumption, easy-to-apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with specific embodiments, but the present invention is not limited to the following embodiments.

[0020] A 6m coke oven is used for coking, the coking time is 20h, and the coke is quenched by dry method. There are six types of coking coal used, namely gas coal, 1 / 3 coking coal, gas fat coal, fat coal, coking coal and lean coal. Gas coal comes from Shandong Zaozhuang Mining Bureau and Xinwen Mining Bureau, 1 / 3 coking coal comes from Henan Pingmei Group, gas-fertilized coal comes from Shandong Xinwen Mining Bureau, fat coal Shandong Zaozhuang Mining Bureau, coking coal comes from Shanxi Coking Coal Group, Lean coal comes from Anhui Huaibei Mining Bureau.

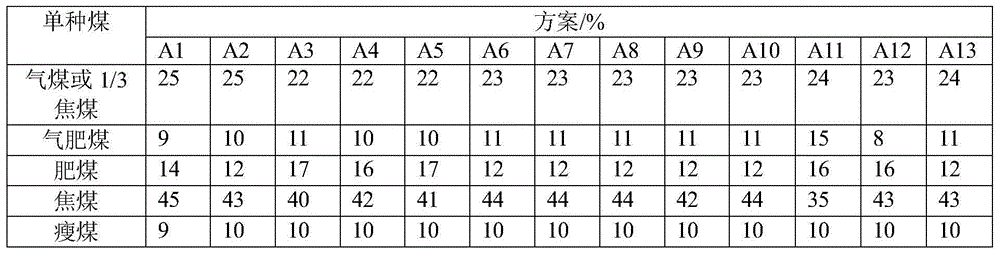

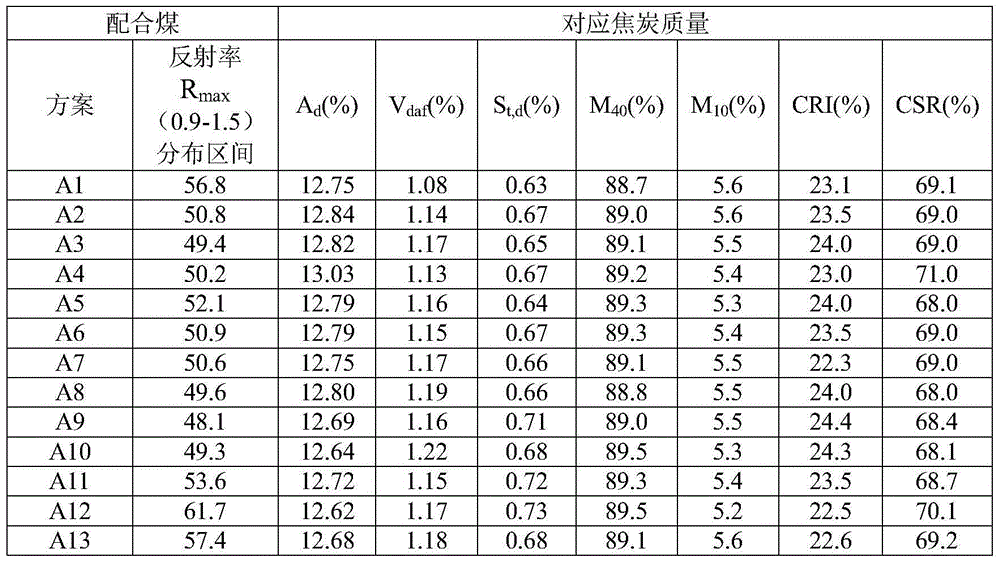

[0021] Firstly, conduct a comprehensive quality analysis of coking coal; secondly, set 13 coal blending schemes for these coal types in different proportions, and choose 1 / 3 of coking coal or gas coal at 22% to 25% for each scheme, and gas-fertilized c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com