Biomass coke tar catalyst with mayenite loaded with calcium and iron compounds as well as preparation and application

A mayenite and catalyst technology, applied in the field of biomass tar catalysts, can solve the problems of high price, deactivation, difficult synthesis gas, etc., and achieve the effects of uniform distribution of active components, improved strength, and reduced carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

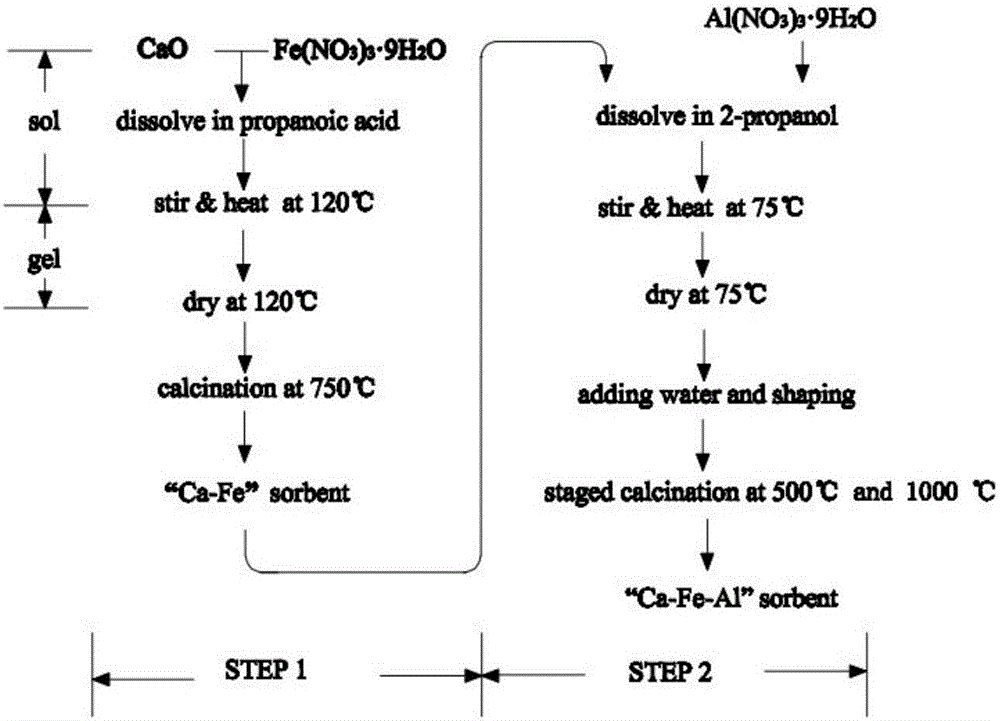

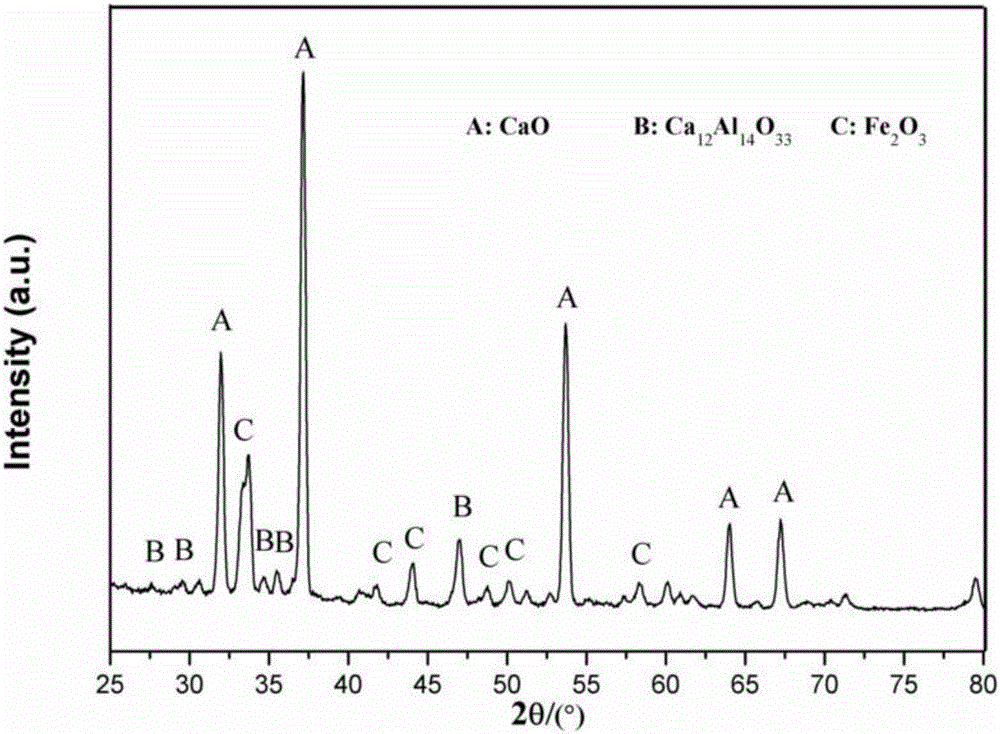

[0031] A mayenite (Ca 12 Al 14 o 33 ) simultaneously load calcium and iron compound novel tar catalyst and its sol-gel method preparation method thereof, comprising the following steps:

[0032] (1) CaO pretreatment. A certain amount of calcium precursor is placed in a muffle furnace and calcined at 500-1000° C. for 2-10 hours. During the high-temperature calcination, the calcium precursor undergoes a decomposition reaction and CaO is obtained. Grinding and sealing the obtained CaO;

[0033] (2) Loading iron active components. The pretreated CaO and a certain stoichiometric ratio of iron precursors were respectively dissolved in excess organic acid solution to obtain a sol. Stir the sol at 110°C to 150°C for 1 to 24 hours to obtain a gel. Then the gel is heated at 100° C. to 200° C. for a certain period of time to obtain a dry gel. Then calcining the xerogel at 500°C-1000°C for 2-10 hours, calcining and decomposing the iron precursor therein into active iron catalytic c...

Embodiment 1

[0036] figure 1 A schematic diagram of the specific process and method for the preparation of the new catalyst, specifically including the following steps:

[0037] Step 1: Preparation of CaO

[0038] A certain amount of Ca(CH 3 COO) 2 ·H 2 O powder was calcined at 850 °C for 2 h. Ca(CH 3 COO) 2 ·H 2 O undergoes decomposition reaction (1) at high temperature to generate CaO solid. Grind the obtained CaO into powder and keep it sealed.

[0039] Ca(CH 3 COO) 2 ·H 2 O=CaO+CO 2 +CH 3 COCH 3 +H 2 O (1)

[0040] The second step: loading iron active components.

[0041] Take 2gCaO and 1.443g Fe(NO 3 ) 3 9H 2 O, so that the weight ratio of Fe atoms to CaO is 1:10. Combining CaO with Fe(NO 3 ) 3 9H 2 O was mixed and dissolved in 393.7ml of propionic acid to obtain a brown-red sol; the beaker containing the sol was placed on an electromagnetic heating stirrer, and stirred at a speed of 250r / min at 120°C for 2h 45min to obtain a brown sol gel; then the gel was dr...

Embodiment 2

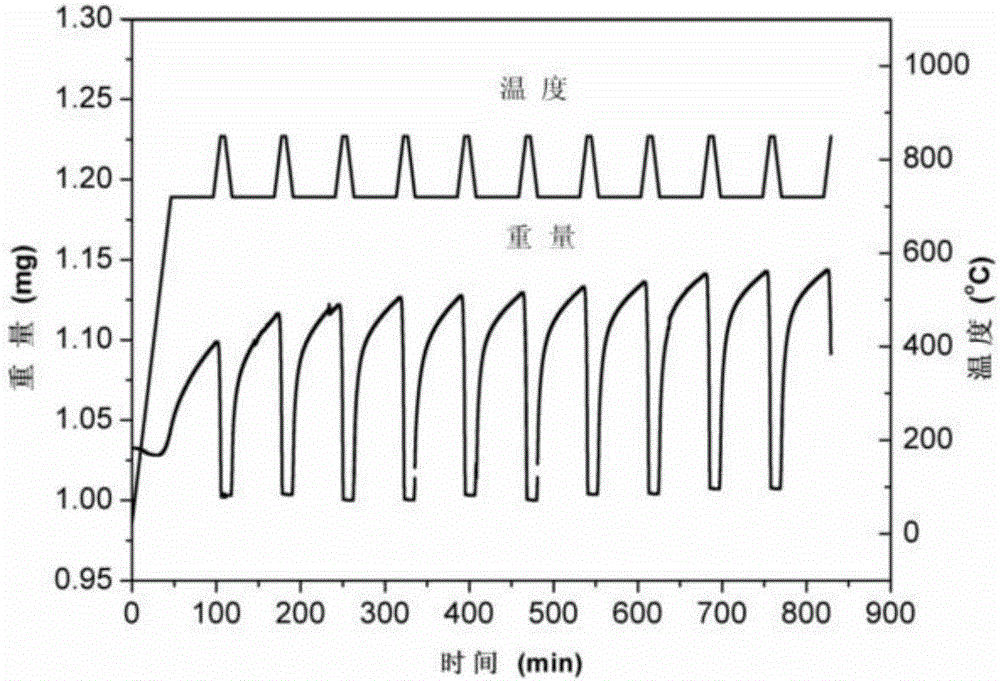

[0048] In order to verify the strength of the catalyst, a test of the cracking strength of the catalyst was carried out. The test method is as follows: place 4 catalyst spherical particles at the four corners of a 4cm×4cm square respectively, place a flat and solid circular wooden board on top of the particles, and keep the wooden board coincident with the center of the square. Gradually add weights on the wooden board until the gravity of the weights simultaneously crushes the four spherical catalysts. The gravity of the weight divided by the area of the square is the fracturing strength of the catalyst particle. For newly prepared carbonation and calcination cycle reactions (carbonation reaction temperature: 720°C, time 50min; calcination reaction temperature: 850°C, time 10min; reaction atmosphere: 15%CO 2 +85%N 2 ) spherical catalysts were tested for their fracture strength. The strength of the fresh catalyst is 65KPa, and the strength of the catalyst after the multi-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com