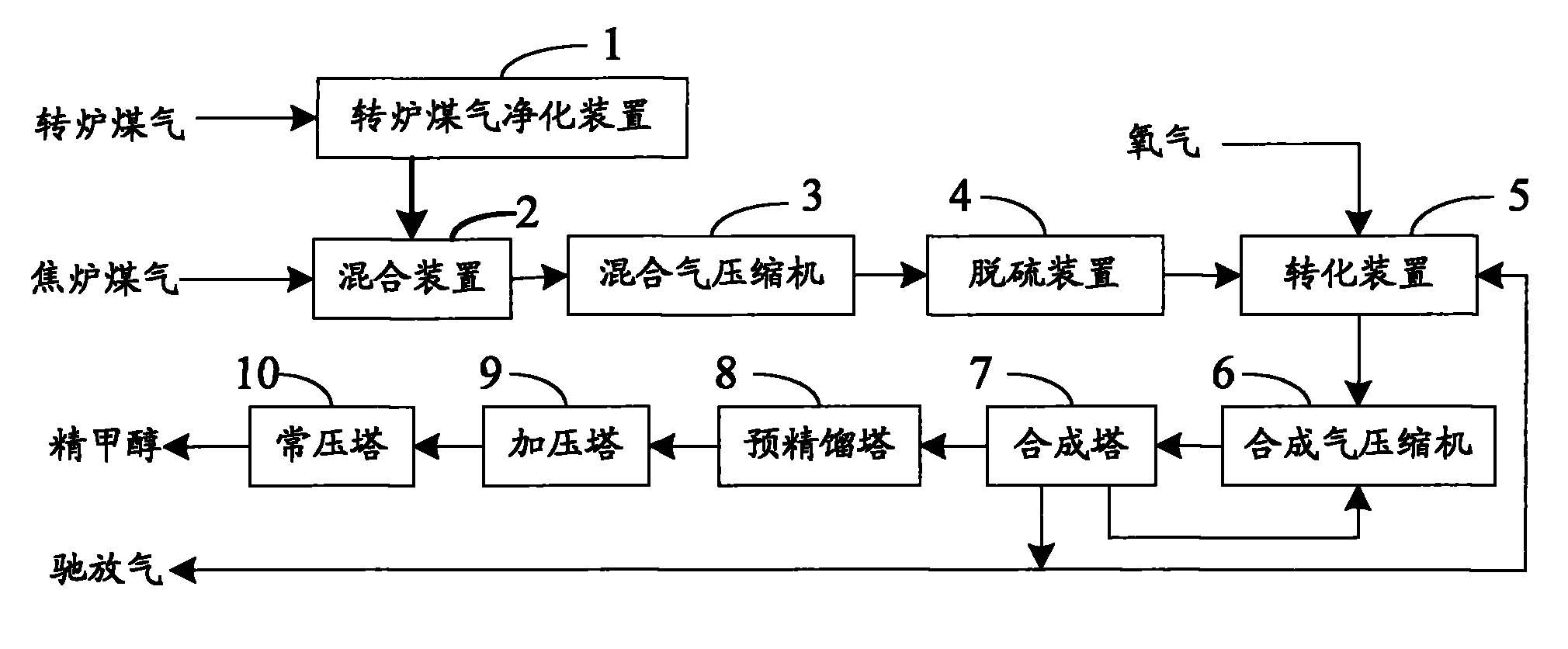

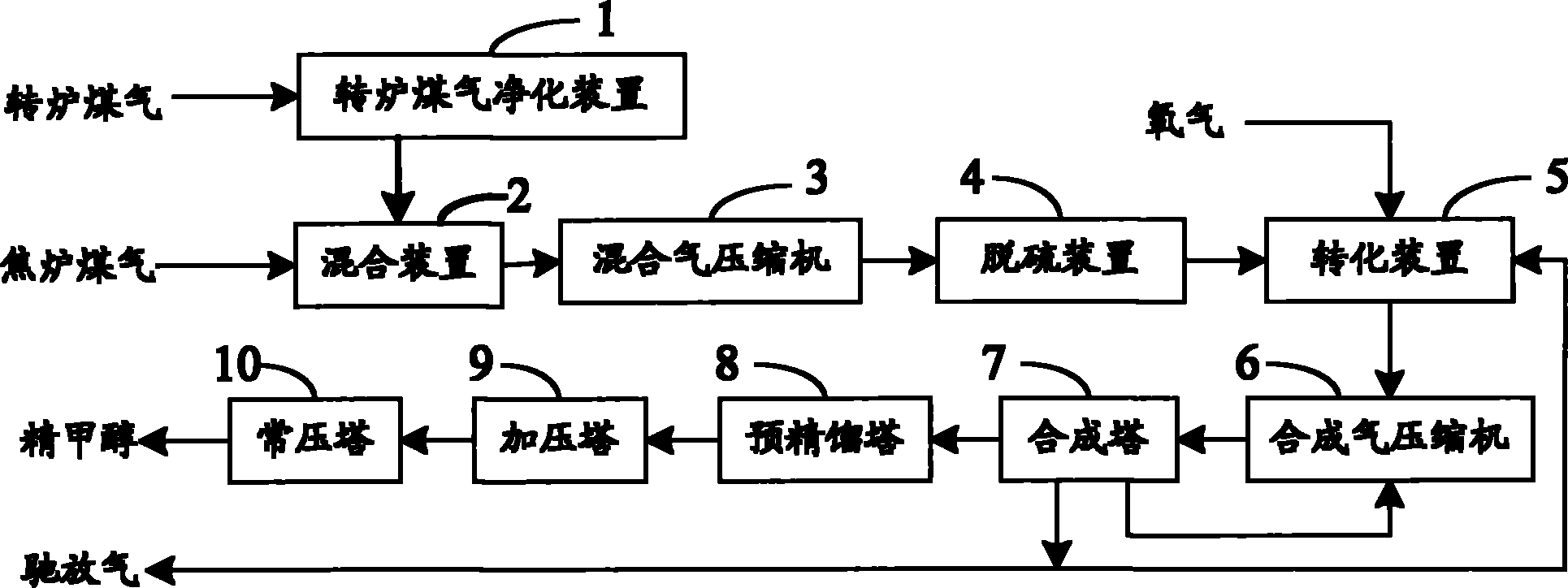

Method and equipment for producing methanol

A methanol and equipment technology, applied in the field of methanol production, can solve the problems of insufficient utilization of hydrogen, waste of resources, and low efficiency of methanol, and achieve the effects of reducing emissions, reducing pollution, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Taking coke oven gas and converter gas produced by steel coke co-production enterprises as raw materials, at a certain moment, the composition of raw materials is:

[0103] The content of each component in coke oven gas is:

[0104] project

[0105] The content of each component in converter gas is:

[0106] project

[0107] The composition and impurities of converter gas before and after purification are as follows:

[0108] project

[0109] Before adding converter gas, the composition of coke oven gas and converted synthesis gas is:

[0110] project

[0111] At this moment, the online analysis of the proportion of the effective components of the synthesis gas required to convert the coke oven gas into methanol is as follows: H 2 is 71.42%; CO is 11.42%; CO 2 was 11.86%. Before the synthesis gas enters the synthesis gas compressor, the temperature is controlled below 40°C, and the pressure is about 2.0Mpa. At this time, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com