Method for purifying HCN and COS in fuel gas produced from coal

A gas and coal-based technology, which is applied in the field of purification treatment of coal-based steelmaking gas, power generation gas and boiler gas, and can solve problems such as high operating temperature and difficulty in using sulfur-containing gas sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

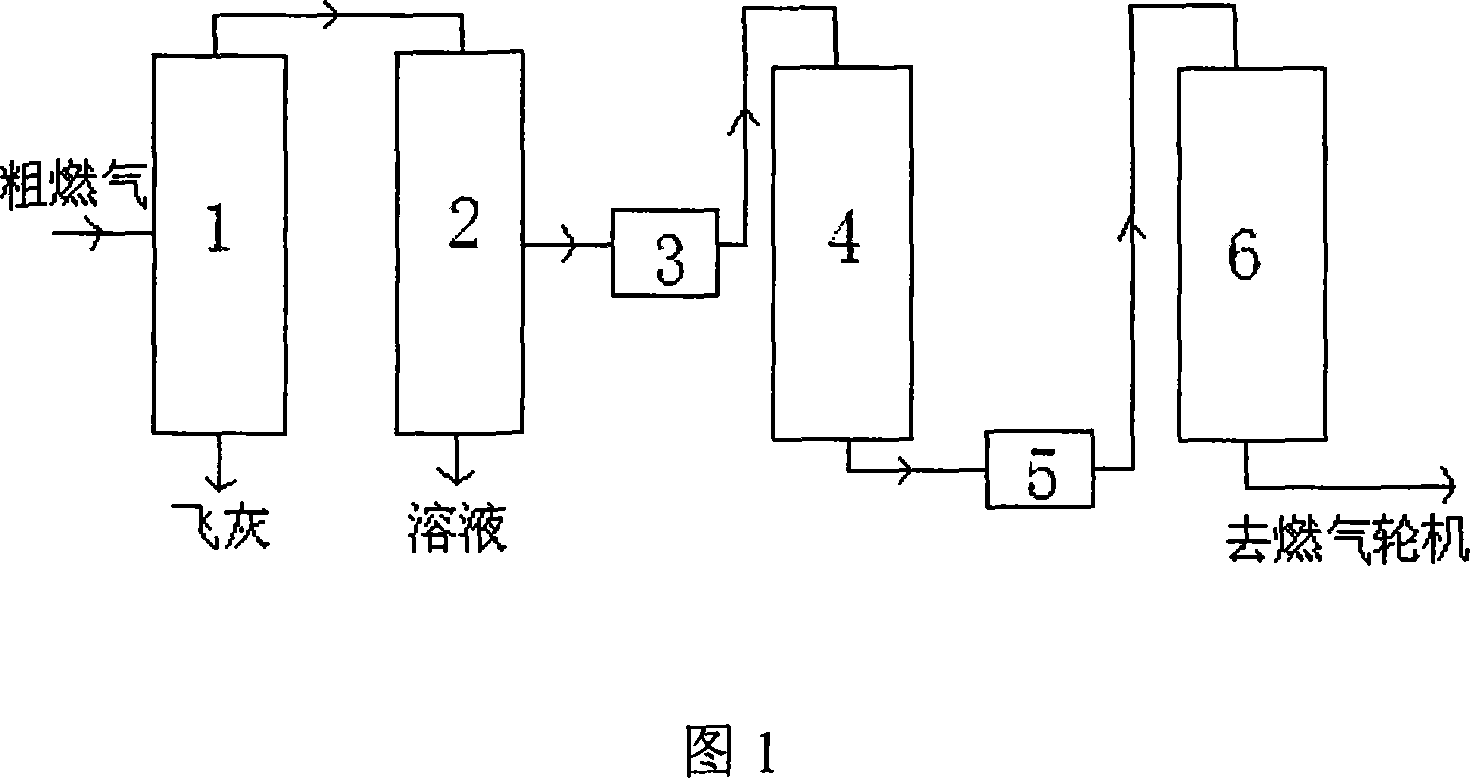

[0015] The specific implementation of the coal-based gas purification method of the present invention in a certain factory is as follows: the crude gas obtained after coal gasification is cooled and dedusted by a ceramic filter, washed with water, and then heated to 170°C and enters the COS and HCN hydrolysis tower from the upper part, and the gas The content of COS in the medium is 135-270ppm, the content of HCN is 50-60ppm, and the interior is 32.7 meters 3 The above-mentioned active alumina carrier supports transition metal cobalt-molybdenum, or iron-molybdenum, or nickel-molybdenum, and a hydrolysis conversion catalyst of basic metal oxides, with an aspect ratio of 2.3 and a space velocity of 2600 hours -1 , the outlet gas at the bottom of the tower is cooled to 40°C by a heat exchanger, and then enters the desulfurization tower equipped with iron oxide fine desulfurizer, and the purified gas can enter the gas turbine. On-site testing shows that the conversion rate of COS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com