Preparation method of nano zinc oxide mesopore desulfurizer

A technology of nano-zinc oxide and nano-sized zinc oxide, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, separation methods, etc., and can solve the problem of hydrogen sulfide removal that has not been found yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

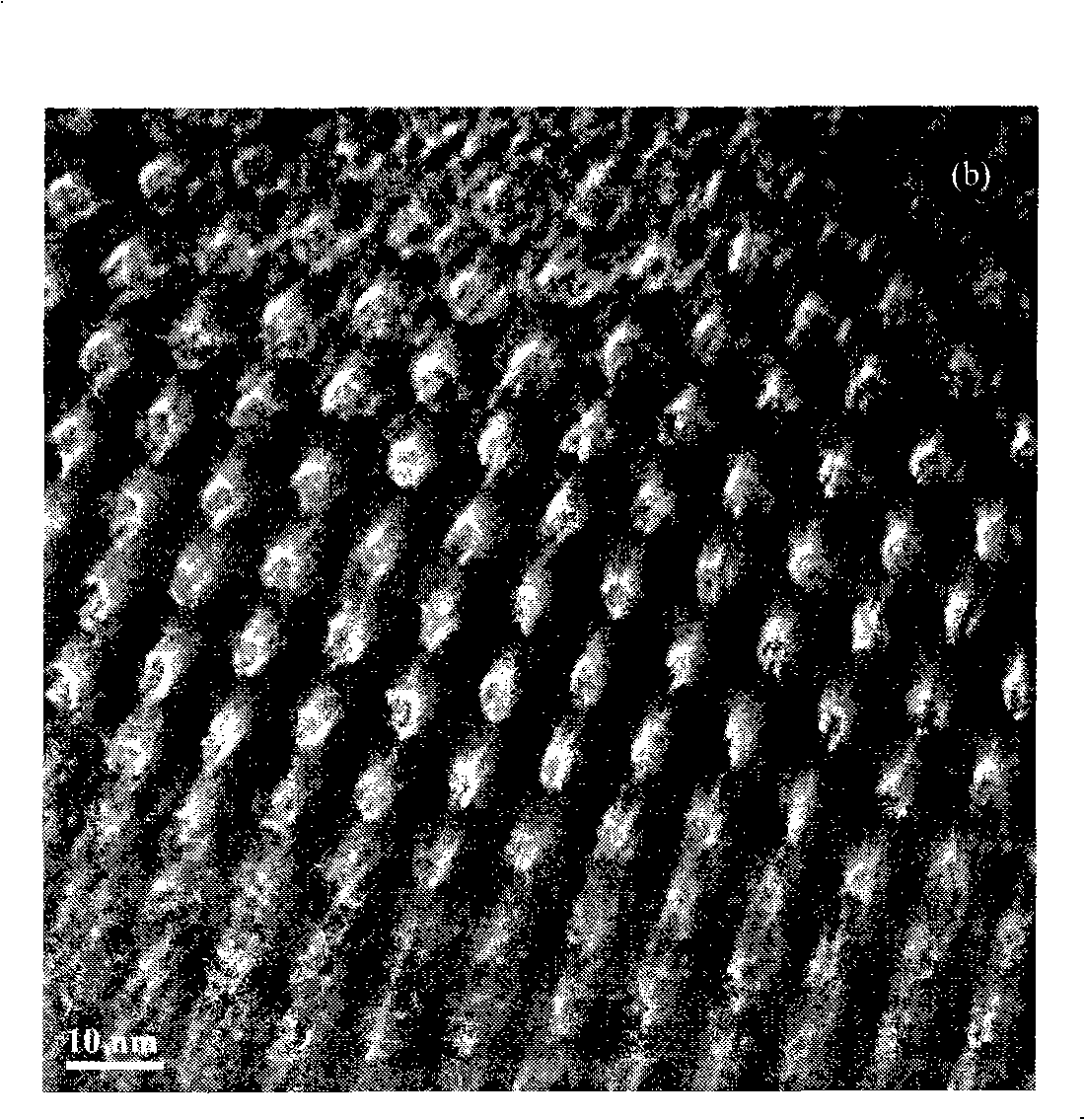

Image

Examples

Embodiment 1

[0024] In the 1M zinc nitrate solution, 2M sodium carbonate solution was added dropwise under stirring condition, and after the addition was completed, it was stirred for 4 hours. The reactants were dehydrated with a centrifuge. The filter cake is washed with 0.1M ammonia water, and the amount of ammonia water is about 200ml. After washing and filtering, continue to wash the resultant with absolute ethanol, then place it in a drying oven, dry it at 393K for 15h, and then roast it at 523K for 1.5h to obtain a white powder, which is Nanoscale zinc oxide particles.

[0025] Weigh 15g of nano-sized zinc oxide particles prepared by the above method, mix them with 100g of mesoporous material SBA-15 in an agate mortar, grind them thoroughly for 20 minutes, and put them in a microwave oven for 10 minutes. Finally, it is formed into a columnar mesoporous desulfurizer.

[0026] The desulfurizer prepared by the above method has a specific surface area of 106m 2 / g, and its total por...

Embodiment 2

[0028] Into the 3M zinc nitrate solution, under stirring condition, 2M sodium carbonate solution was added dropwise, and after the addition, stirred for 2 hours. The reactants were dehydrated with a centrifuge. The filter cake is washed with 0.1M ammonia water, and the amount of ammonia water is about 200ml. After washing and filtering, continue to wash the resultant with absolute ethanol, then place it in a drying oven, dry it at 393K for 15h, and then roast it at 523K for 1.5h to obtain a white powder, which is Nanoscale zinc oxide particles.

[0029] Weigh 1 g of nano-sized zinc oxide particles prepared by the above method, mix them with 100 g of mesoporous material SBA-15 in an agate mortar, grind them thoroughly for 20 min, and put them in a microwave oven for 10 min. Finally, it is formed into a columnar mesoporous desulfurizer.

[0030] The desulfurizer prepared by the above method has a specific surface area of 412m 2 / g, and its total pore volume can reach 0.91cm...

Embodiment 3

[0032] The preparation method of nano-zinc oxide particles is the same as Example 1.

[0033]Weigh 8 g of nano-sized zinc oxide particles prepared by the above method, mix them with 100 g of mesoporous material SBA-15 in an agate mortar, grind them thoroughly for 20 min, and put them in a microwave oven for 10 min. Finally, it is formed into a columnar mesoporous desulfurizer.

[0034] The desulfurizer prepared by the above method has a specific surface area of 336m 2 / g, and its total pore volume can reach 0.69cm 3 / g. When the outlet hydrogen sulfide concentration reaches 10ppm, the breakthrough sulfur capacity of the prepared nano zinc oxide mesoporous desulfurizer reaches 296mg / g mesoporous desulfurizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com