Cold metal transition welding method and device thereof

A technology of cold metal transfer and welding device, applied in welding equipment, metal processing equipment, arc welding equipment, etc., can solve the limitation of welding quality and production cost of weld seam, unstable droplet transfer form, and limitation of weld seam forming characteristics and other problems, to achieve the effects of easy control of welding line energy, poor wetting and spreading, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

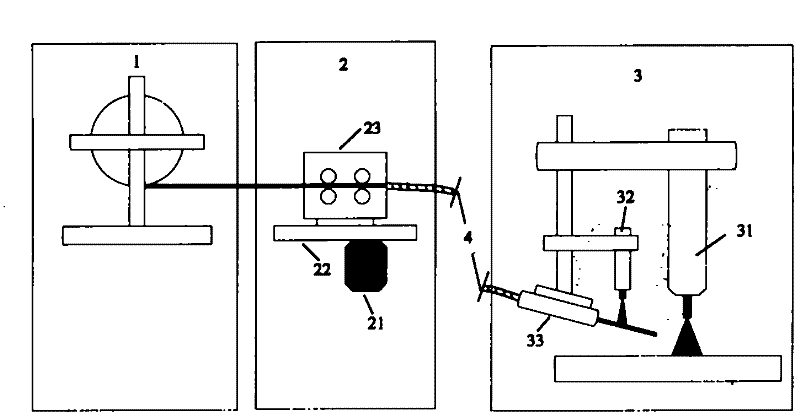

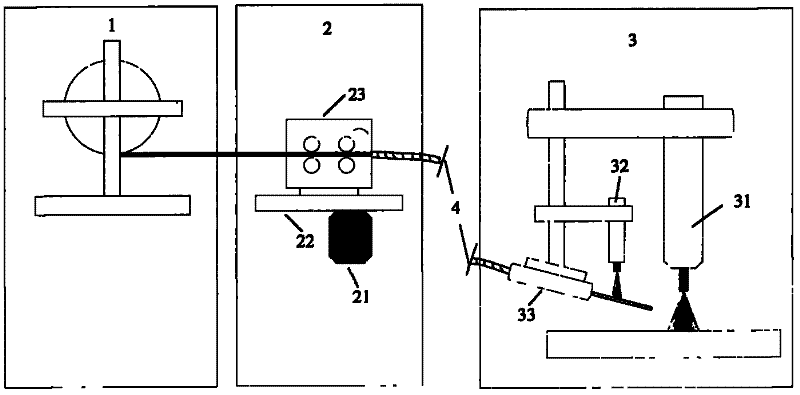

[0015] Example 1: Combining figure 1 , the present invention is a welding device for cold metal transition, which is composed of MAG welding automatic wire feeding unit (1), vibrating wire feeding unit (2), argon arc hot wire welding torch unit (3) and flexible pipe (4) , the MAG welding automatic wire feeding unit (1) is connected to the vibrating wire feeding unit (2), and the vibrating wire feeding unit (2) is connected to the argon arc hot wire welding torch unit (3) through a hose (4), and the vibrating wire feeding unit (2) Including vibrating motor (21), eccentric turntable (22) and double-drive wire feeding box (23), vibrating motor (21) is connected with eccentric turntable (22), eccentric turntable (22) is connected with double-drive wire feeding box (23) ), described argon arc hot wire welding torch unit (3) comprises straightener (33), auxiliary electric arc welding torch (32) and main TIG electric arc welding torch (31), and straightener (33) connects auxiliary el...

Embodiment 2

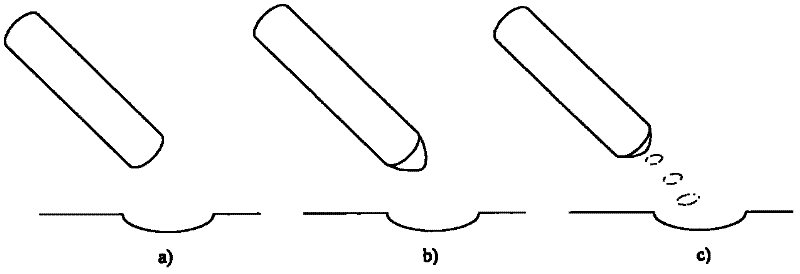

[0021] Example 2: Combining figure 1 , figure 2 , the welding method of a kind of cold metal transition of the present invention, adopt argon arc to preheat welding wire, and argon arc directly heats the welding wire stretched out from the straightener, and the distance between the heating position and the welding wire end is 10-15mm, and the power pole of the hot wire arc is The positive connection method is selected according to the welding wire material. Copper alloys are connected with direct current to improve the effect of hot wire. Aluminum alloy welding wires are connected with direct current or AC power. The oxide film on the surface of the welding wire is removed through cathode atomization, and the vibration motor drives the eccentric turntable to drive The wire feeding drive box draws back, causing the end of the welding wire to vibrate. According to the arrangement of the eccentric turntable, it can be divided into horizontal plane retraction and vertical plane v...

Embodiment 3

[0026] Example 3: Binding figure 1 , the actual welding parameters of the present invention:

[0027] The workpiece substrate is a 35CrMnSi cylinder with a diameter of 60mm and a thickness of 5mm. The welding wire is 201 red copper wire for copper alloy surfacing welding. The main TIG arc welding current is 240A, the auxiliary hot wire current is 40-60A, the auxiliary voltage is 20V, and the wire feeding speed is is 2-4m / min, the rotation speed of the vibrating motor is 3000-3600r / min, the eccentric distance is set to 1.5mm, the distance between the hot wire arc and the end of the welding wire is 15mm, and the welding method and device for cold metal transition of the present invention are obtained. High quality copper alloy overlay. The principle of determining the welding specification is: the size, performance, and joint form of the welding object should be considered comprehensively, and should be reasonably matched with the equipment parameters and process parameters. Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com