Air injecting and backflow flue gas entraining heat exchanger for radiant tube combustion device

An air injection and combustion device technology, which is applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of large air flow resistance loss, low combustion air temperature, and low heat exchange efficiency, and achieve easy installation The effects of disassembly, increased turbulence, and increased heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

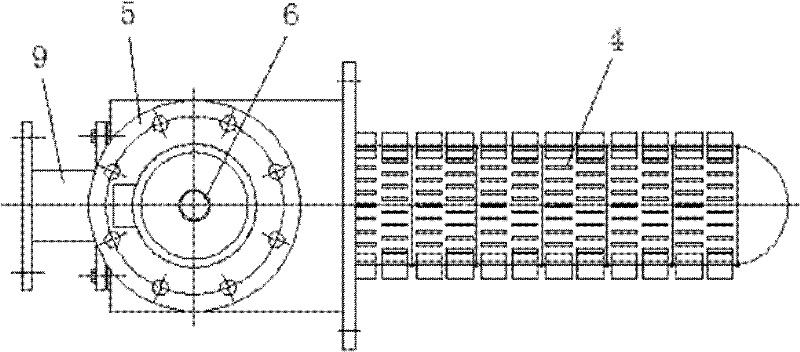

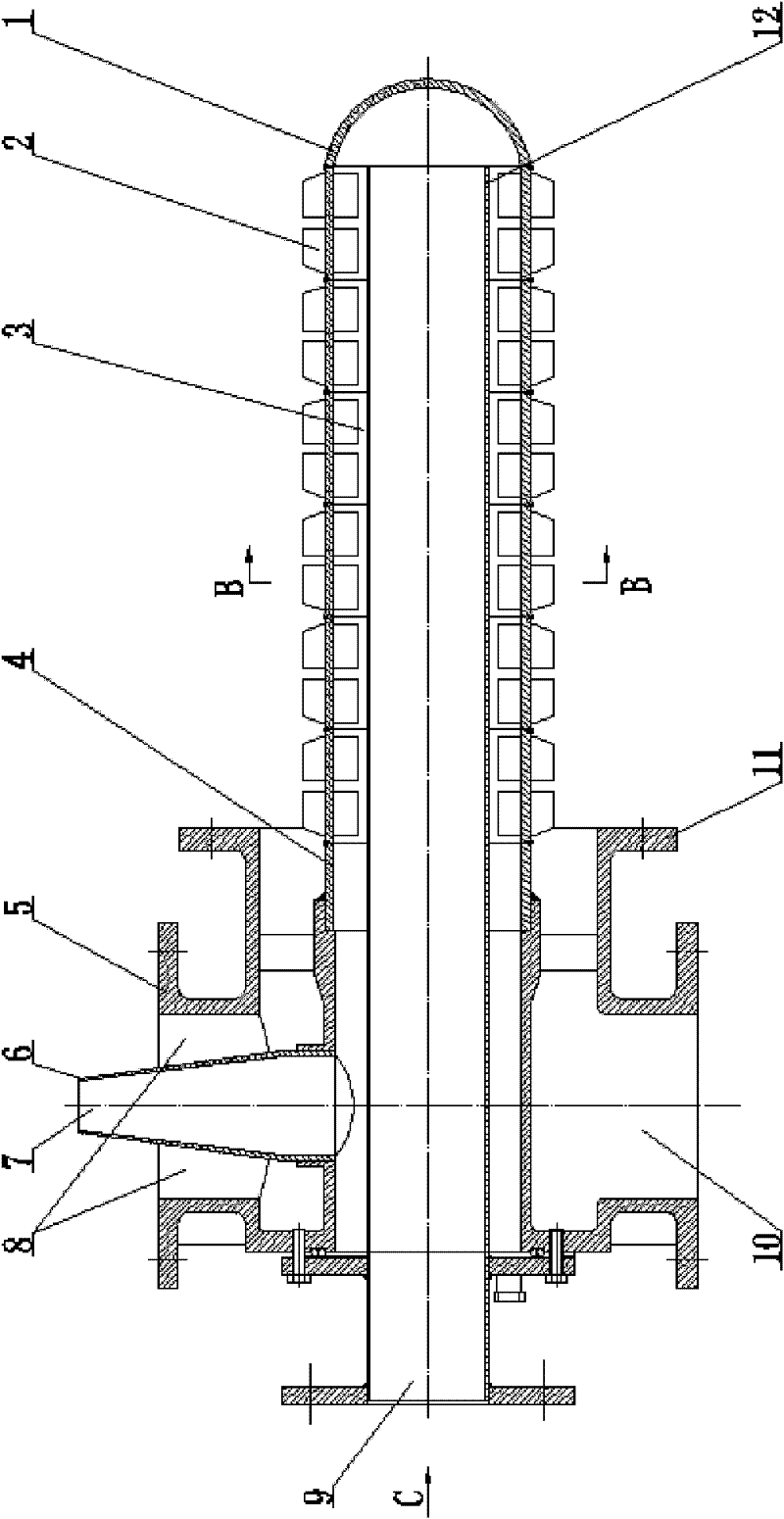

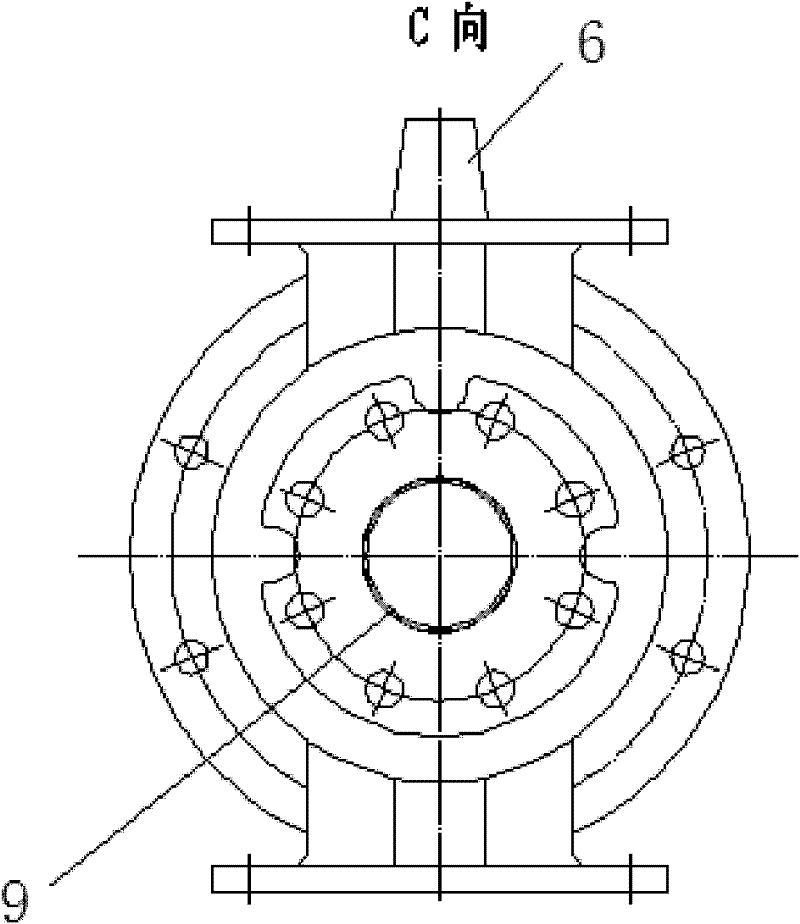

[0021] In order to better understand the present invention, the technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments. Figure 1 to Figure 5 .

[0022] According to the heat exchanger for a radiant tube combustion device with air jet entraining and returning flue gas according to the present invention, the whole heat exchanger includes a heat exchanger shell 5 , a high temperature air jet tube 6 , a heat exchange tube, and an inner core tube 12 . The heat exchanger shell 5 is a four-way structure made of heat-resistant steel. It has an air inlet, a flue gas inlet, a flue gas outlet, and an air jet mixing port. The inner core tube 12, the high temperature air jet tube 6, and the heat exchange tube are all It is connected to the heat exchanger shell 5 and forms a continuous channel through the shell 5 . When used together with the radiant tube combustion device, the flue gas inlet end of the heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com