Self-pre-heating type nozzle for efficient helical fin

A spiral-finned, high-efficiency technology, applied in the field of self-preheating burners, can solve the problems of large heat loss, increased emission, and high flue gas temperature, so as to increase the temperature of preheated air, reduce the temperature of flame combustion, and reduce The effect of NOx generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

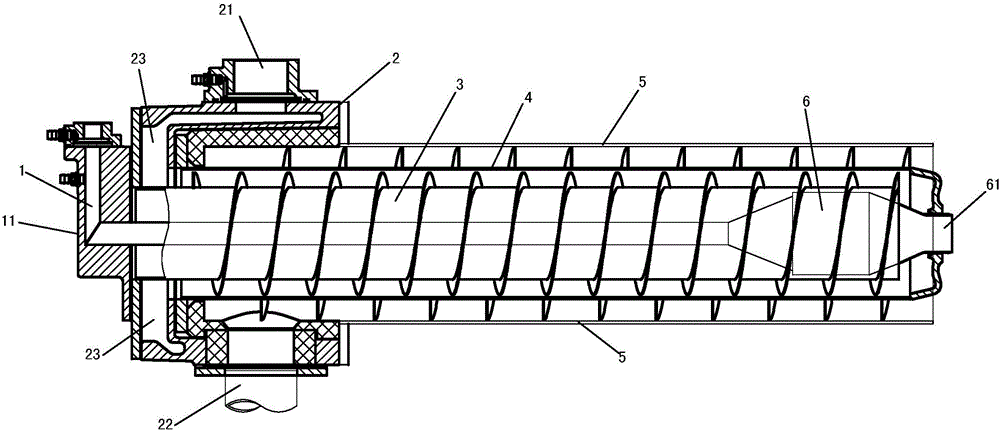

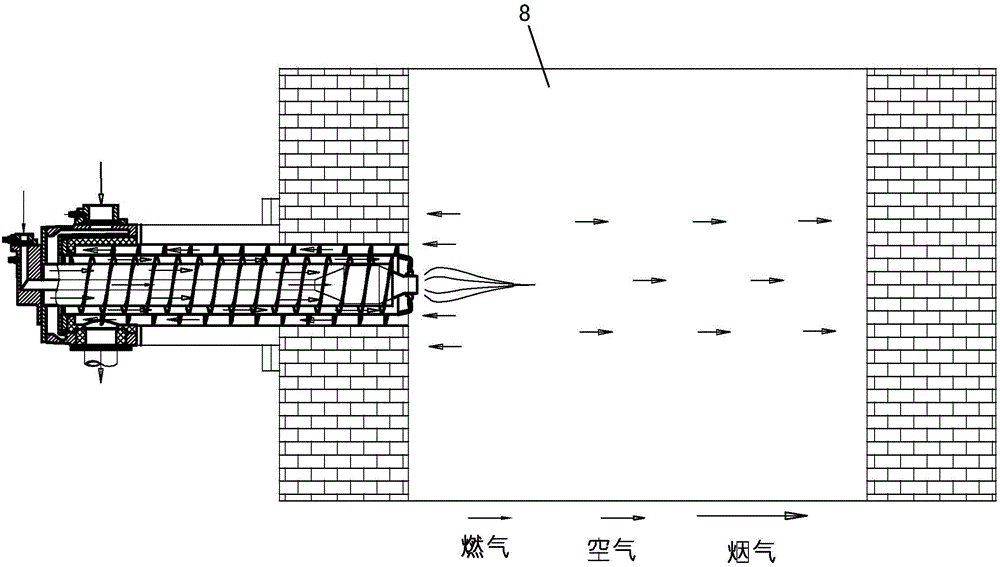

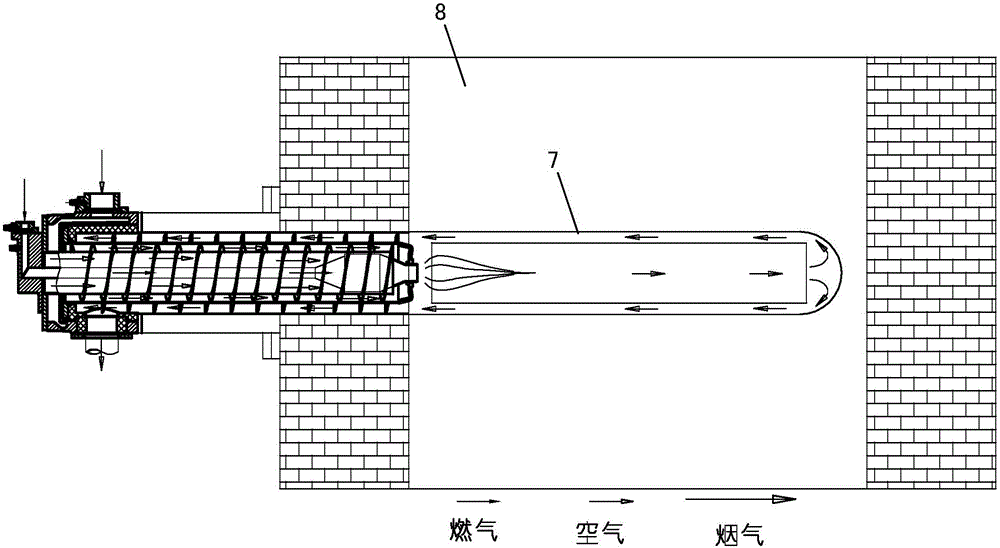

[0011] see Figure 1-3 As shown, the present invention relates to a high-efficiency spiral fin self-preheating burner, including a gas pipe 1, an air shell 2, an air port 21 and an exhaust port 22 arranged outside the air shell 2, and a spiral fin The air duct 3, the spiral fin heat exchanger tube 4, the air housing 2 is provided with an air cavity 23, the air cavity 23 communicates with the air port 21, and the front end of the spiral fin air duct 3 is fixedly arranged in the air Inside the shell 2 and communicated with the air cavity 23, the spiral fin heat exchanger tube 4 is sleeved on the surface of the spiral fin air duct 3, and the front end of the spiral fin heat exchanger tube 4 is set on the air shell 2 Inside and communicated with the air cavity 23, the surface of the spiral fin heat exchanger tube 4 is sleeved with a flue gas conduit 5, the flue gas conduit 5 communicates with the exhaust port 22, and one end of the gas pipe 1 is arranged on the spiral fin The air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com