Preheating and insulation device for laser selective melting forming

A technology of laser selective melting and heat preservation device, which is used in ceramic molding machines, process efficiency improvement, manufacturing tools, etc., can solve the problems of easy cracking and difficult to meet the forming needs, and achieves good heat insulation, high forming precision of parts, Improve the effect of preheating and heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

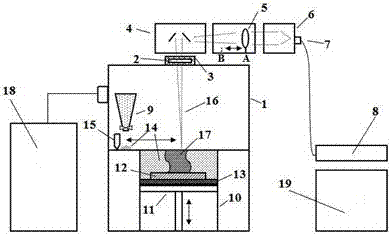

[0018] A preheating and heat preservation device for laser selective melting and forming, including an optical path system, a vacuum forming chamber 1, a control system 19, an external vacuum device 18 and a molding cylinder 10, and the control system 19 controls the optical path system and the vacuum forming chamber 1 , an external vacuuming device 18 and a forming cylinder 10, the optical path system is placed above the vacuum forming chamber 1, the optical path system is sealed and connected with the vacuum forming chamber 1 through the protective lens 2, and the vacuum forming chamber 1 is vacuumed with the outside The device 18 is connected, and the optical path system includes a laser beam 16, a laser device 8, a collimating beam expander mirror 6, a focusing mirror 5, an X direction and a Y direction deflection mirror 4, and the laser beam 16 is collimated after being generated from the laser device 8 The beam expander 6, the focusing mirror 5, the X-direction and Y-dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com