Triple-stroke air-preheating radiant tube burner heat exchanger

An air preheating radiation, three-stroke technology, applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as poor heat transfer efficiency, reduce heat loss, reduce heat transfer surface temperature, and improve air preheating. The effect of hot temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, the present invention is further described:

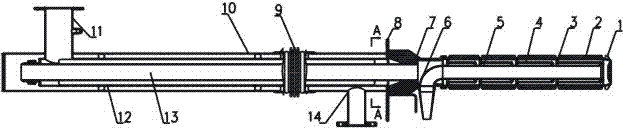

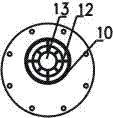

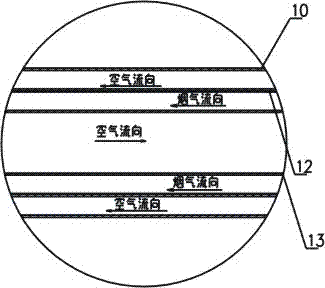

[0033] see figure 1 and figure 2 , Three-stroke air pre-tropical flue gas diversion and entrainment structure radiant tube burner heat exchanger, the heat exchanger is divided into two parts: built-in heat exchange and external heat exchange. The part of the built-in heat exchange area includes the end plug 1, which adopts a diversion-shaped structure design, is precision cast and formed, and is fixed with the inner finned tube 2 through continuous sealing welding. The inner finned tube 2 is formed by precision casting of heat-resistant steel, and the outer fin structure is designed. The fins are evenly arranged along the tube wall of the heat exchange tube, and the arrangement varies from 36 to 54 per circle according to the diameter of the heat exchange tube. The internal finned tubes 2 are fixed by continuous sealing welding. The porous jet tube 4 is formed by numerical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com