Heat storage gas heating device and heat storage gas heating method

A gas heating device and regenerative technology, which is applied in high-efficiency heating, regenerative heat exchange and heating, and high-temperature fields, can solve problems such as maintenance troubles and low heating efficiency, and achieve thermal efficiency improvement, labor intensity reduction, and preheating temperature Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and accompanying drawings.

[0017] It should be noted here that the descriptions of these embodiments are used to help the understanding of the present invention, but are not intended to limit the present invention.

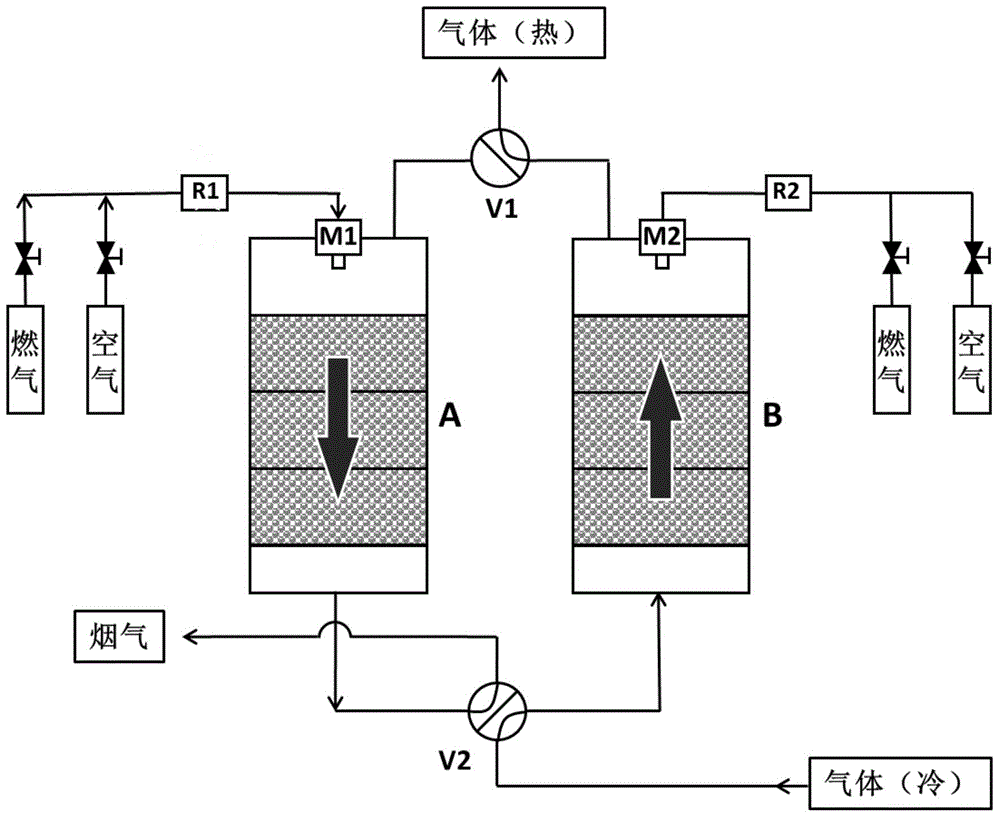

[0018] figure 1 It is the working flow chart of the first half cycle of the regenerative gas heating device. Gas and air on the left are sprayed into the combustion chamber from the nozzle M1 and burned. The high-temperature flue gas generated enters the regenerator A and heats the regenerator. Since the ceramic regenerator in the regenerator is composed of the same ceramic modules stacked and connected in series, heat transfer to each other is hindered, so the temperature difference between the inlet and outlet of the regenerator is extremely large, and the temperature of the flue gas drops rapidly below 200°C, and finally passes through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com