Method for heating glass melting furnace with sectional combustion oxygen fuel burner mounted on the top

A glass melting furnace, oxy-fuel technology, which is applied to gas fuel burners, combustion with multiple fuels, and air/fuel supply for combustion, etc. , the effect of glass quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

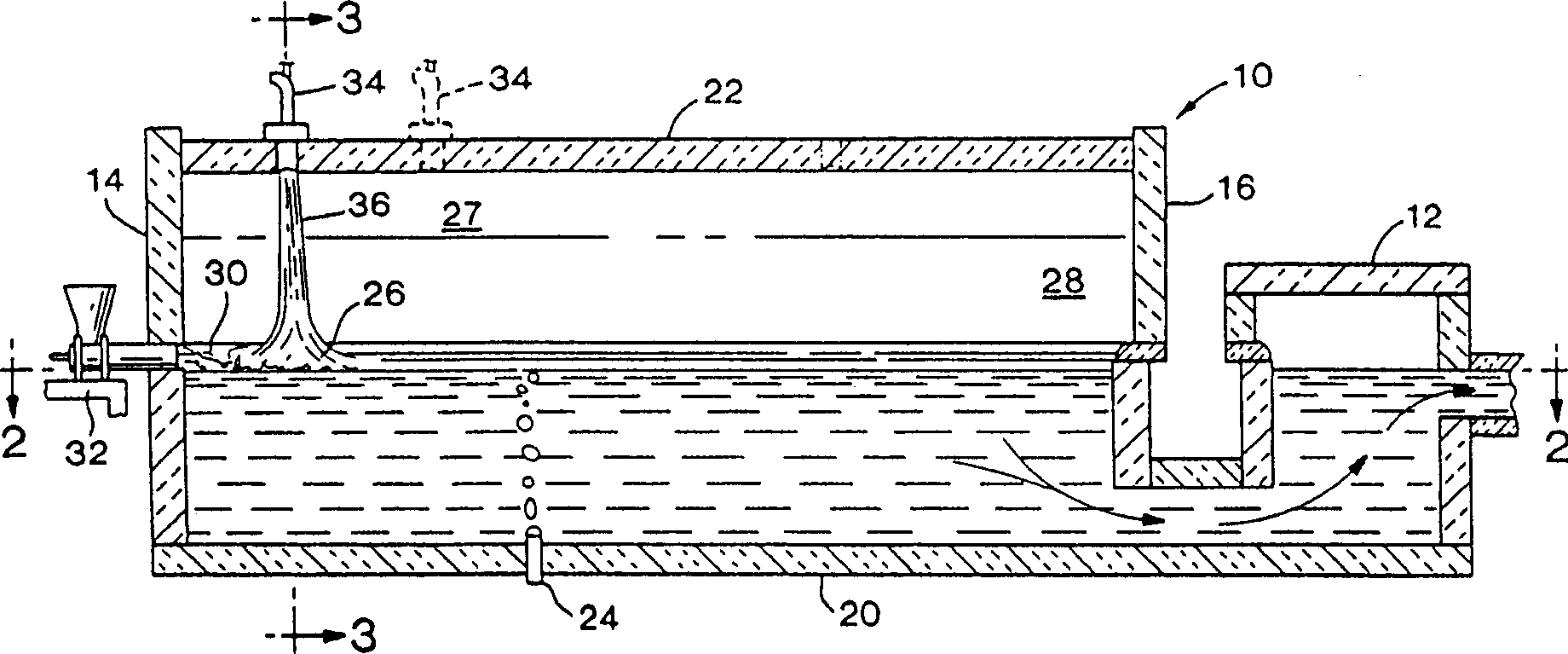

[0113] Example 1 retrofitted with top mounted oxy-fuel burners

[0114] A demonstration of the present invention is oxygen heating—transformed into 100% oxygen, and then converted into oxygen to increase heat, and finally form the traditional air fuel ignition of the existing 3-heat opening cross-fired reciprocating furnace. The furnace initially ignites all air fuel. The ignition of port #1 is replaced with at least one top mounted oxy-fuel burner. The furnace ignites the air-fuel that exchanges heat over the remaining two openings in the conventional manner. In the second stage, at least one top-mounted oxy-fuel burner is then used to replace the ignition of port #2 and conventionally ignite the air-fuel regenerating over the third port. In the third stage, the ignition of opening #3 is replaced with energy from the oxy-fuel burner already installed on the top. The furnace capacity was increased from 55 to 85 tons per day and the energy input was reduced from 23.5mm BTU / h...

example 2

[0115] Example 2 Burner and burner block with integral oxygen segments

[0116] By means of the structure of the burner or the burner combined with the burner block shows an oxy-fuel burner provided with an oxygen integral section which increases heat transfer and reduces NO x . According to the invention, the roof 111 of the glass melting furnace 110 is provided with at least one integrally segmented burner 103 of this type. The burner 103 is ideally located above the raw batch 130, and is preferably angled so that the angle α( Figure 6 α) in the direction along the glass flow 104 in the furnace is approximately equal to 91° to 135°.

example 3

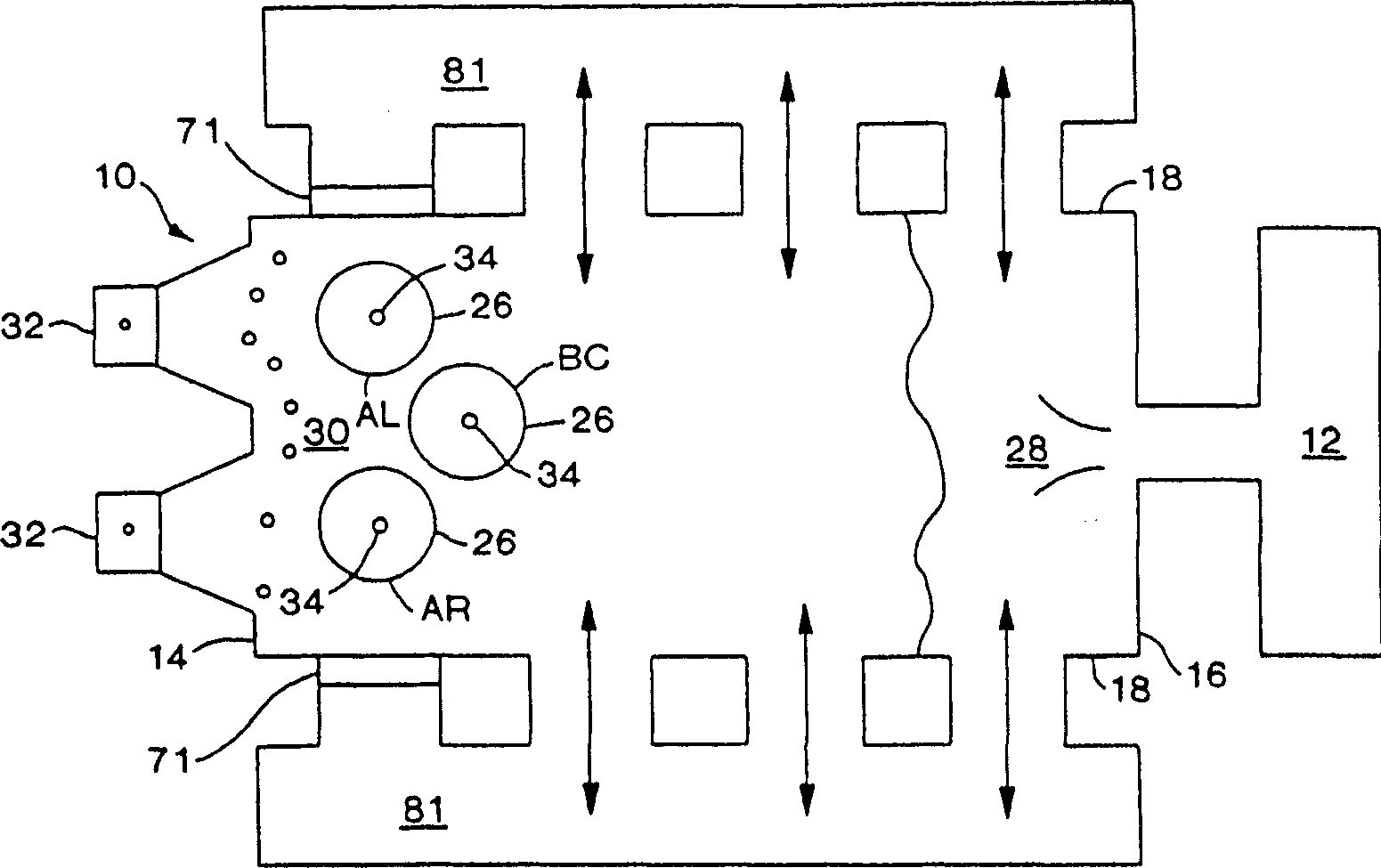

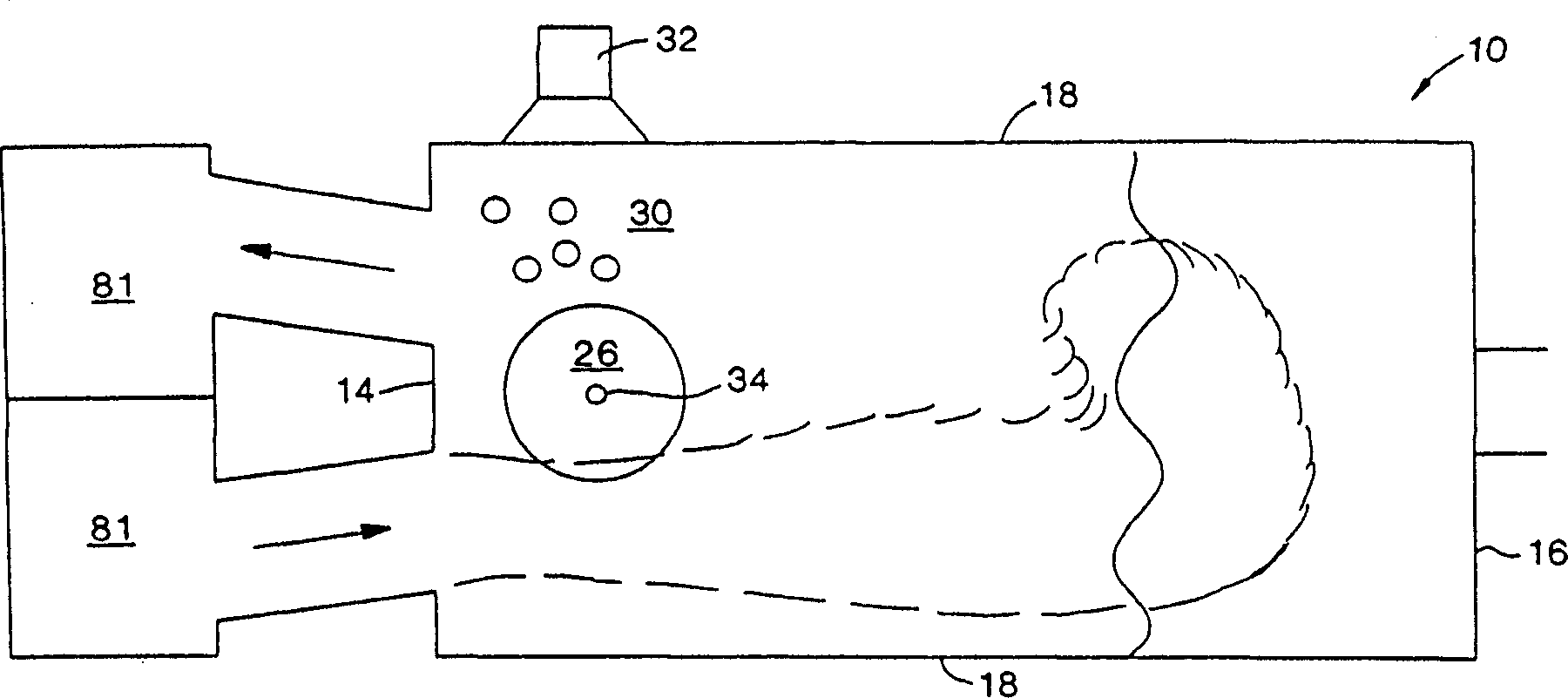

[0117] Example 3 Burner and burner block with external oxygen segments

[0118] See Figure 7 , the figure shows a burner 122 with a burner body 121 installed on the top of a glass melting furnace 111, the burner 122 has 2-8 oxygen injectors 112 outside the burner 122 and the furnace body 121, This burner can produce a higher heat transfer than an unstaged burner. The burner 122 is preferably angled from about 91° to about 135° relative to the glass surface and along the direction of glass flow in the furnace. According to this example, a stoichiometric ratio of 0% to about 90% of the injected oxygen is injected through the primary oxygen burner 133, and the remaining 100% to about 10% of the secondary combustion oxygen 134 is injected through the oxygen burner 112, which 112 makes an angle from about 0° to about 90° relative to the glass surface. As understood by those skilled in the art, the number, angle and degree of segmented openings are designed specifically for each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com