Sheet glass stove

A glass furnace, flat technology, used in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of undesired material stress, uneven heating, obvious problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

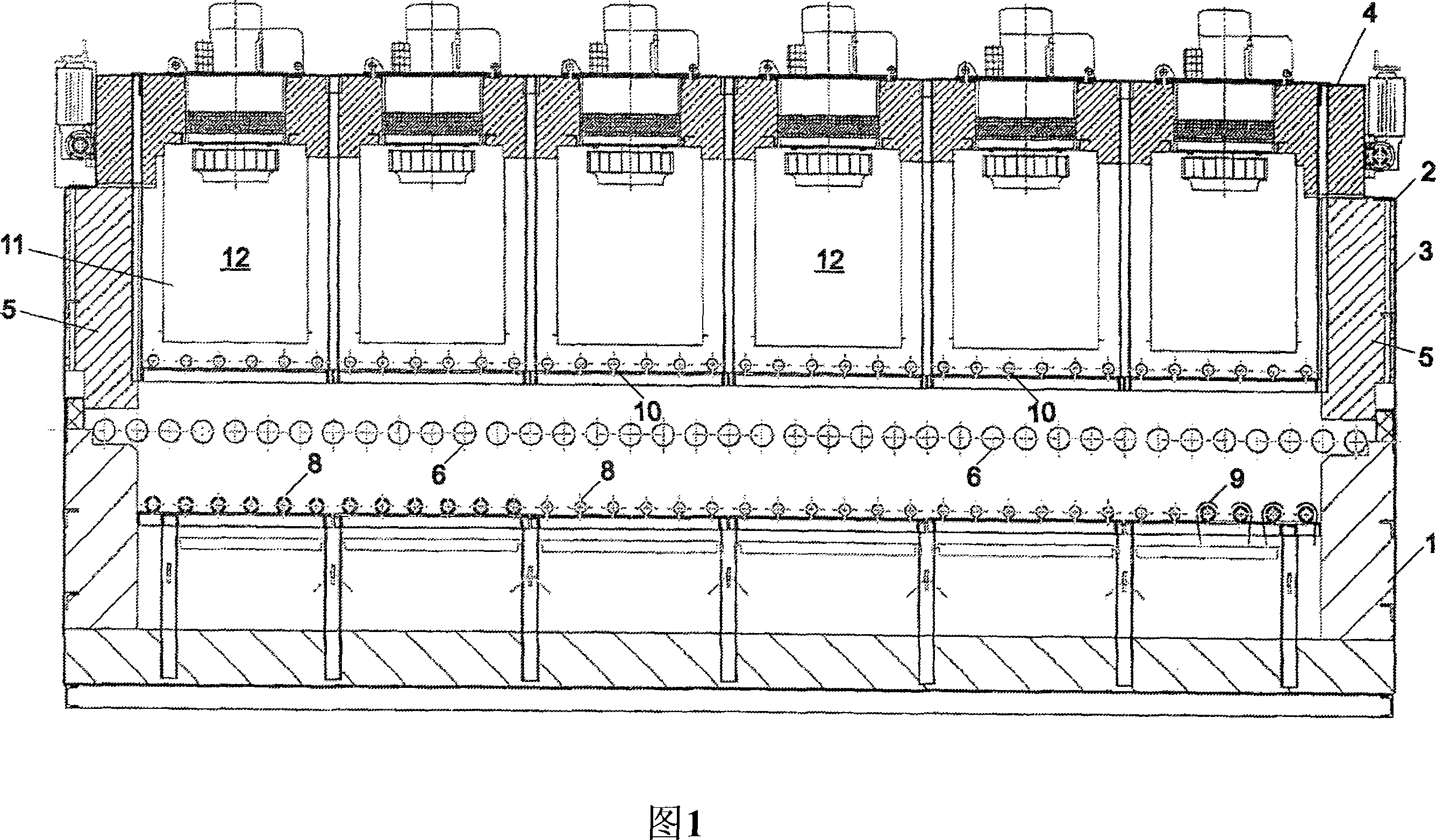

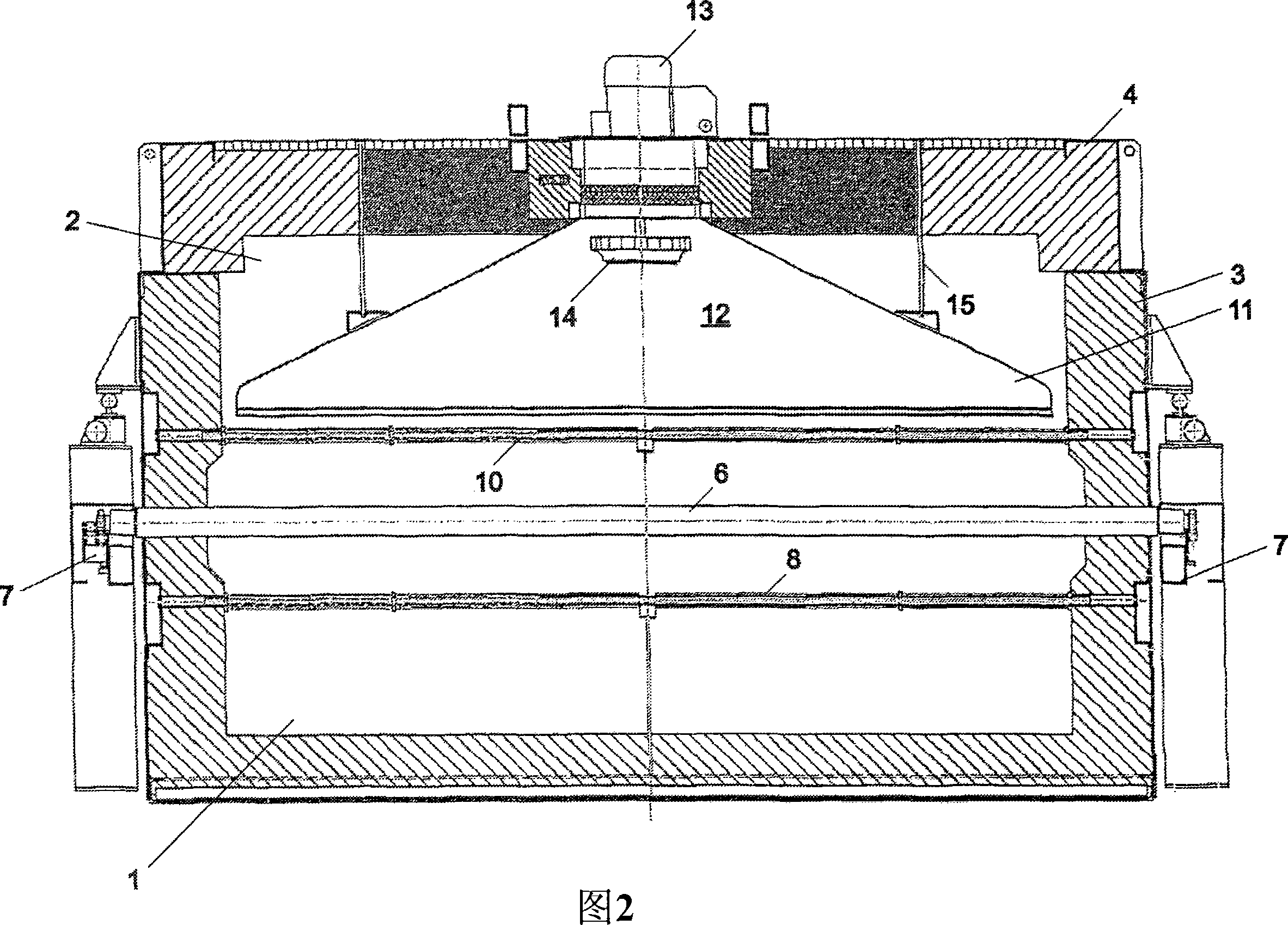

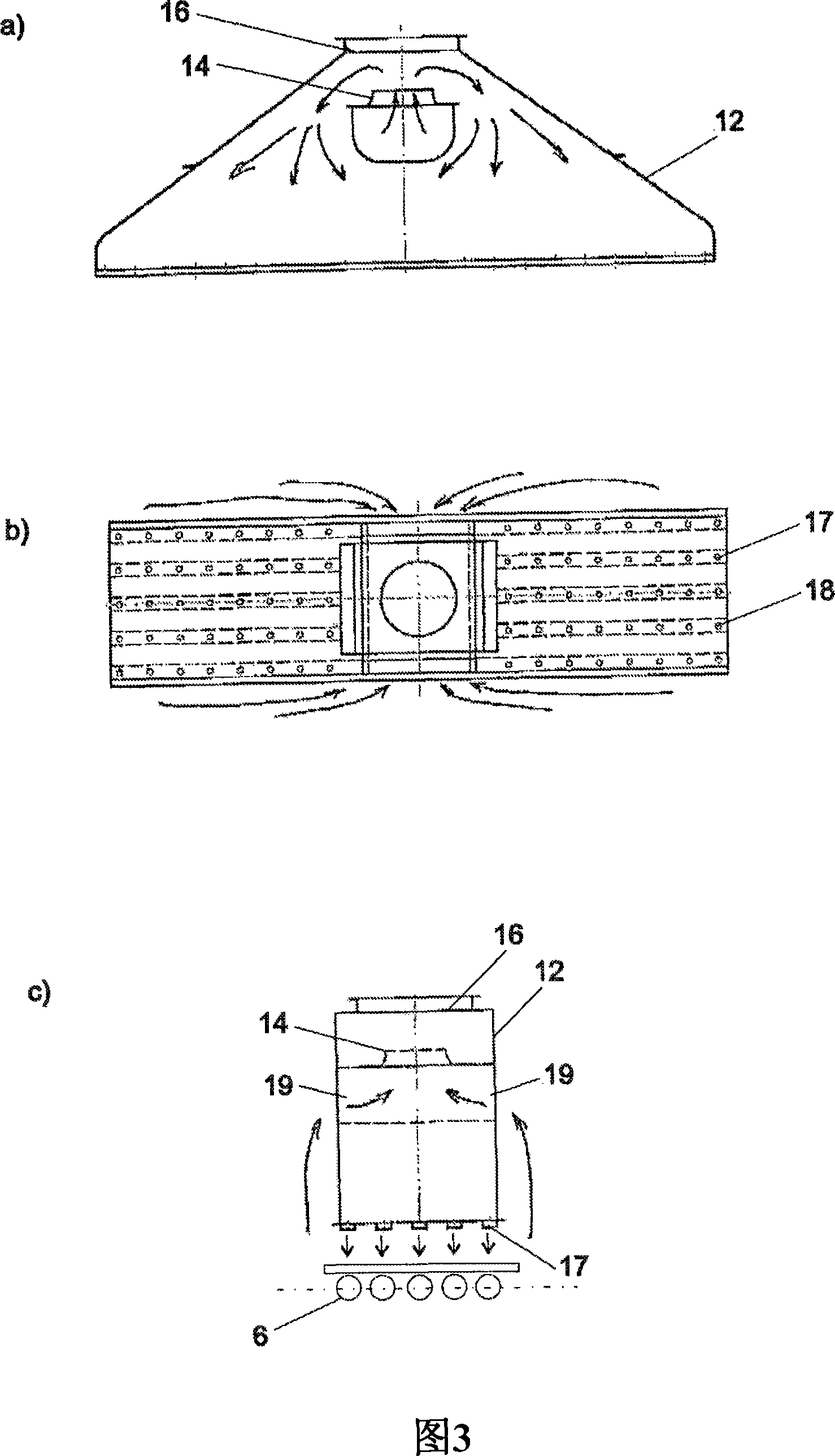

[0019] 1 and 2 show a simplified longitudinal and cross-sectional view of a planar glass furnace according to the invention. The flat glass furnace has a furnace lower part 1 and a furnace upper part 2 with a central part 3 and a roof 4 . The middle part of the furnace upper part and the top hood are separable from each other for maintenance purposes. At the entrance and exit of the middle part 3 there are lift gates 5 which can be moved by corresponding lifting equipment.

[0020] In the lower part 1 of the furnace, a row of furnace rollers 6 extends over the entire length of the furnace, the axes of rotation of which are perpendicular to the conveying direction. The furnace roller 6 is preferably made of quartz material, and its ends are movably laid on roller drive brackets 7 installed at both ends. The furnace rollers are driven, for example, by frequency-controllable drive motors, and by using toothed belt drives. In order to precisely align the furnace rollers at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com