Glass furnace temperature control method based on deep learning and reinforcement learning

A temperature control method and reinforcement learning technology, applied in the direction of temperature control using electric methods, auxiliary controllers with auxiliary heating devices, etc., can solve the problems of untimely and inaccurate manual adjustment, achieve good prediction and control, and overcome The effect of concept drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the drawings and embodiments.

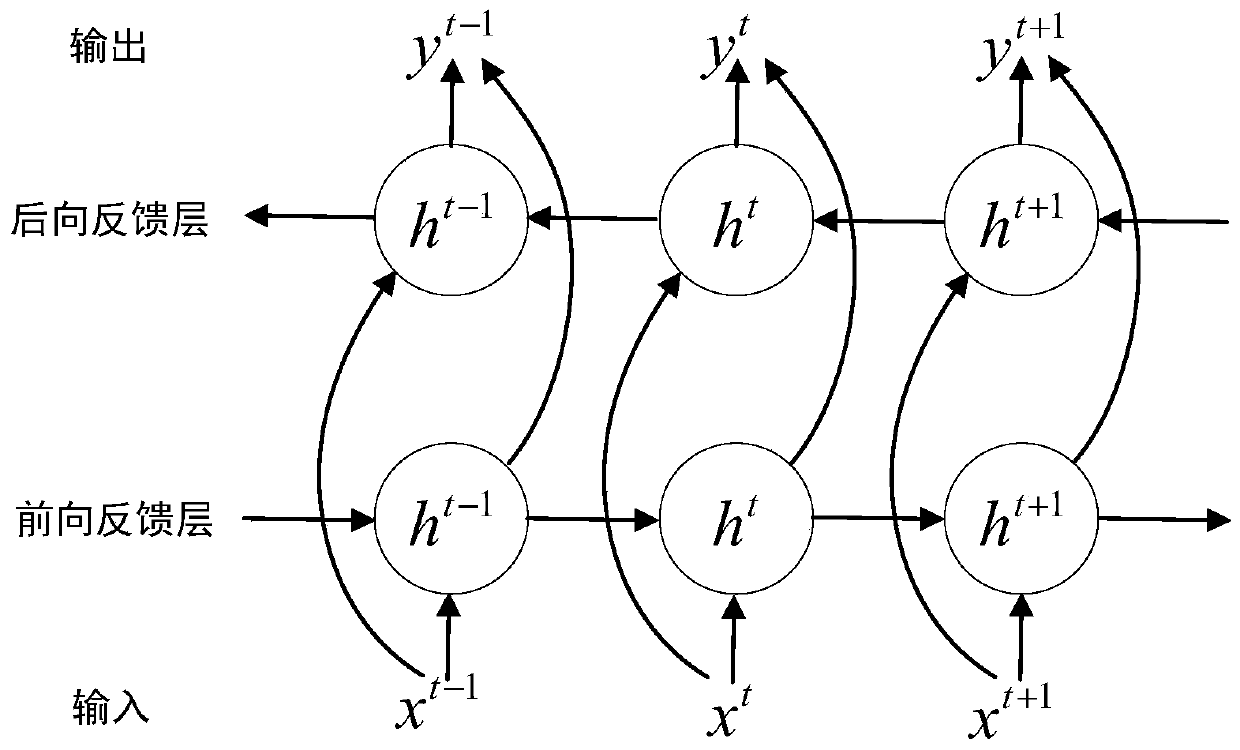

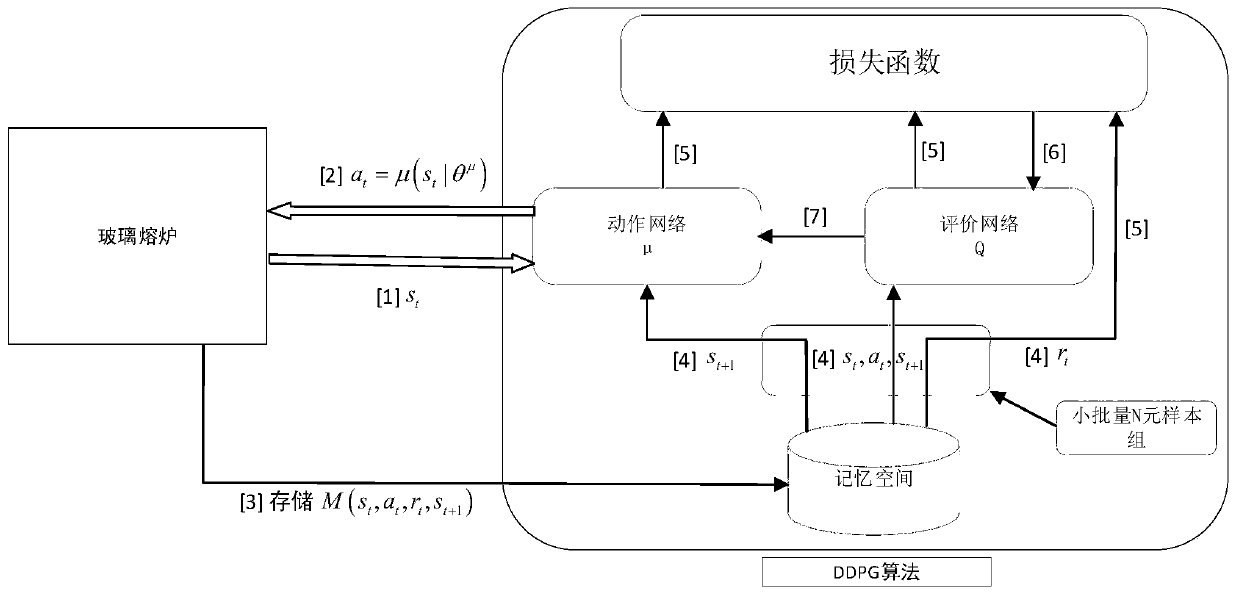

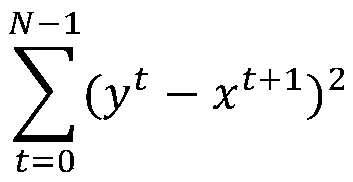

[0022] The invention provides a kiln temperature control method based on deep learning and reinforcement learning, which adjusts the valve openings of oxygen and natural gas in the kiln according to the set values of each key temperature point, so that the temperature environment of the kiln remains stable. This method uses a deep neural network to establish a kiln temperature simulation model based on key characteristic quantities such as kiln historical temperature, pressure, natural gas and oxygen flow, and valve opening, which is used to simulate the kiln temperature change environment. Based on the temperature simulation model, according to the real-time environment of the current kiln temperature, pressure, fuel concentration, etc., combined with deep neural network and reinforcement learning algorithm, the kiln temperature control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com