Solid glass micro-bead for explosive identification and manufacture method thereof

A technology of solid glass microspheres and marking, applied in the field of materials, can solve the problems of small explosive marking capacity, inability to provide information for identification and traceability, and achieve the effect of increasing the marking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

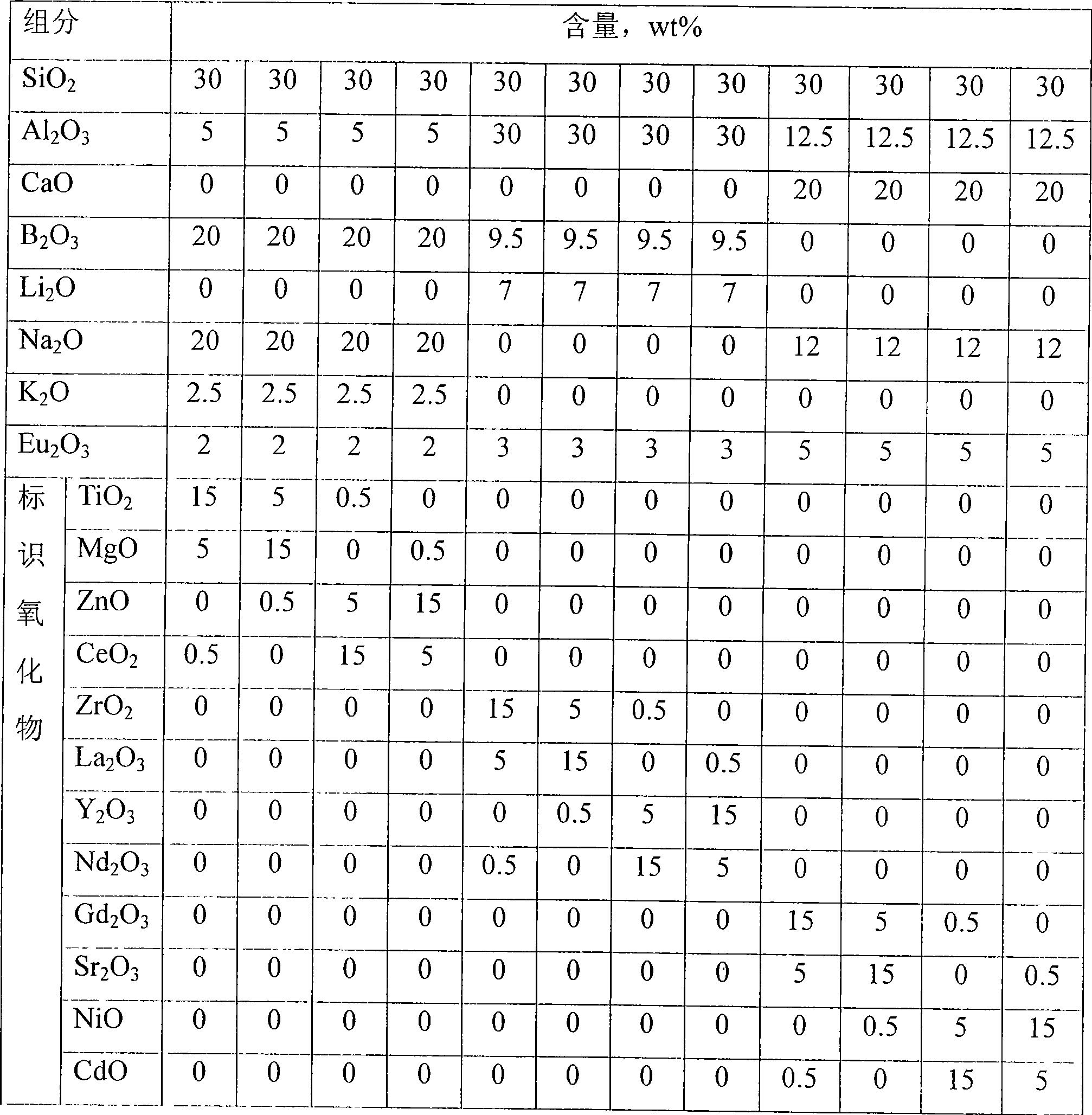

[0015] A series of glass microspheres prepared in this example are mainly used to mark explosives with low explosive strength and low instantaneous temperature of explosion, which are characterized by low melting temperature and the largest particle size. Several typical formulations of this series are shown in Table 1:

[0016] Table 1

[0017]

[0018] The concrete preparation process of this embodiment is:

[0019] a. Batch and mix the raw materials according to the formula, put them into a glass melting furnace for melting at 1200-1280°C, and keep warm for 2-4 hours;

[0020] b. Quickly pour the fully melted and evenly stirred glass melt into cold water for quenching to obtain fully uniform and broken glass;

[0021] c. Break the broken glass and sieve out glass particles with a particle size of 600-2000 μm;

[0022] d. Use a powder feeder to send glass particles into a high-temperature flame with a temperature higher than the melting temperature of the glass in the ...

Embodiment 2

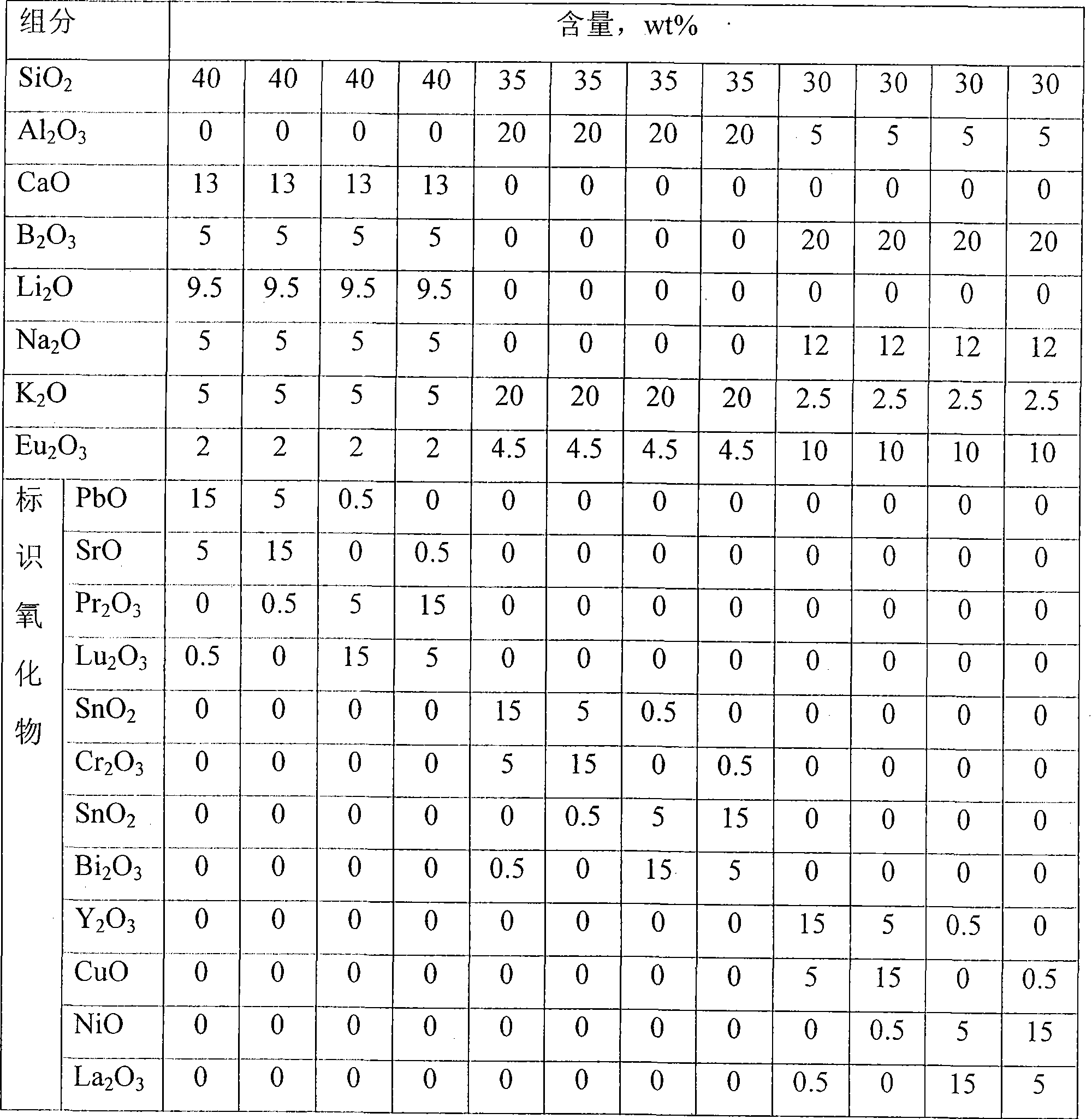

[0024] A series of glass microspheres prepared in this example are mainly used to mark explosives with medium to high explosion intensity and medium to high instantaneous temperature of explosion, which are characterized by high melting temperature and moderate particle size. Several typical formulations of this series are shown in Table 2:

[0025] Table 2

[0026]

[0027] The concrete preparation process of this embodiment is:

[0028] a. According to the formula, the raw materials are batched and mixed, put into a glass melting furnace for melting at 1300-1400°C, and keep warm for 4-8 hours;

[0029] b. Quickly pour the fully melted and evenly stirred glass melt into cold water for quenching to obtain fully uniform and broken glass;

[0030] c. Crush the broken glass and sieve out glass particles with a particle size of 200-800 μm;

[0031] d. Use a powder feeder to send glass particles into a high-temperature flame with a temperature higher than the melting temperat...

Embodiment 3

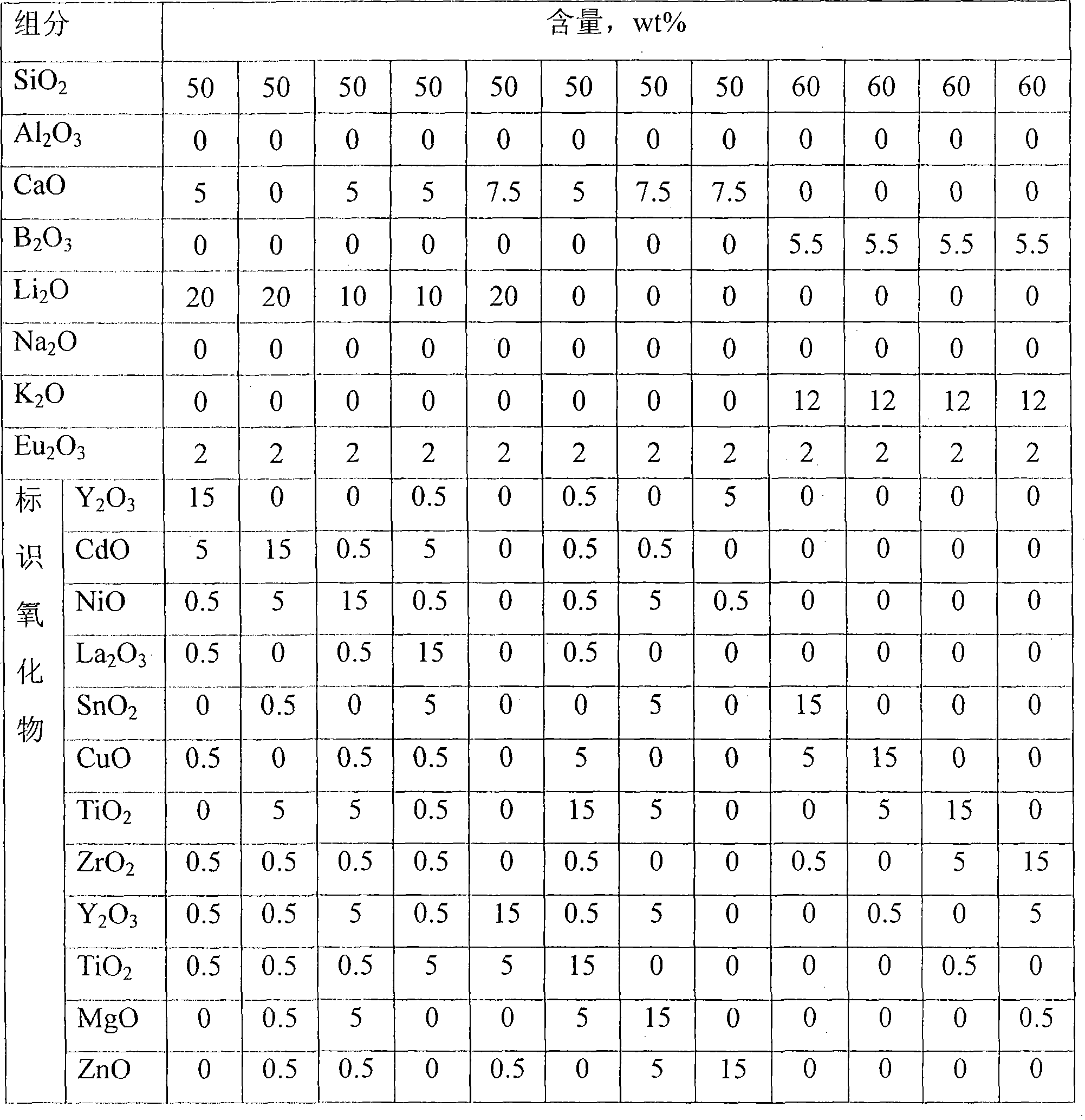

[0033] A series of glass microspheres prepared in this example are mainly used to mark explosives with the strongest explosive strength and the highest instantaneous temperature of explosion, which are characterized by the highest melting temperature and the smallest particle size. Several typical formulations of this series are shown in Table 3.

[0034] table 3

[0035]

[0036] The concrete preparation process of this embodiment is:

[0037] a. Batch and mix the raw materials according to the recipe, put them into a glass melting furnace for melting at 1450-1550°C, and keep warm for 6-10 hours;

[0038] b. Quickly pour the fully melted and evenly stirred glass melt into cold water for quenching to obtain fully uniform and broken glass;

[0039] c. Crush the broken glass and sieve out glass particles with a particle size of 10-200 μm;

[0040] d. Use a powder feeder to send glass particles into a high-temperature flame with a temperature higher than the melting tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com