Molten iron tank alignment tractor below blast furnace

The technology of a tractor and a molten iron tank is applied in the field of tractors, which can solve the problems of molten iron splashing, waste of equipment resources and energy, hurting people, etc., and achieve the effects of preventing molten iron splashing, reducing transportation costs, and preventing misoperation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

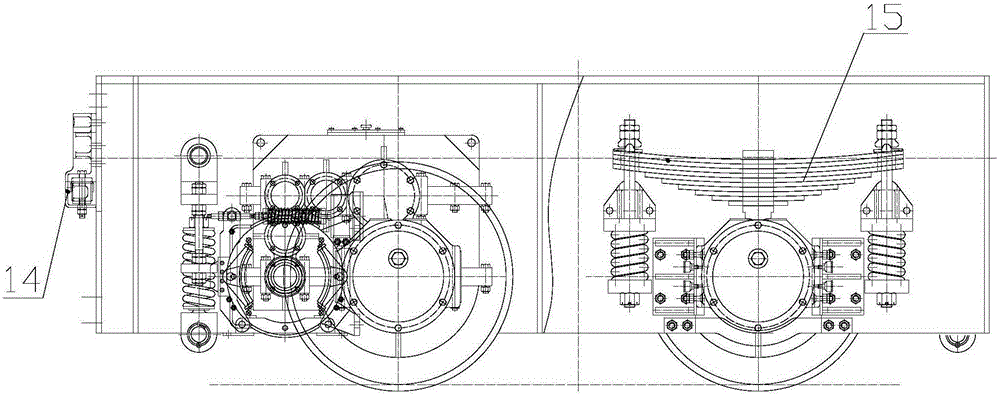

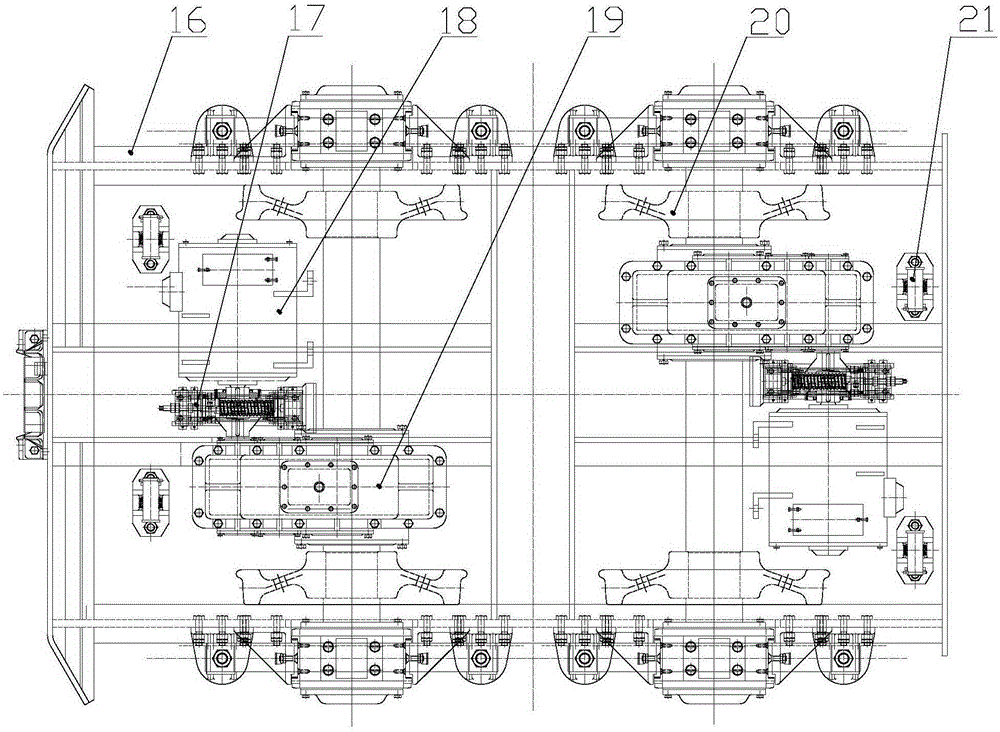

[0034] The invention relates to a tractor for aligning molten iron tanks under a blast furnace, comprising a car body 8 controlled by the main control system of the tractor. The main control system is provided with a main control module, which is wirelessly connected to the external remote controller 22 through the remote control signal receiver; a rotary encoder is installed on the output shaft of the reducer 19 of the ladle tank alignment tractor, and the rotary encoder is aligned with the tractor The control system is connected. The alignment control system of the tractor includes at least a single-chip microcomputer, a key circuit, a display module and a communication module. The communication module is also connected with the main control system of the tractor and the blast furnace tapping control system.

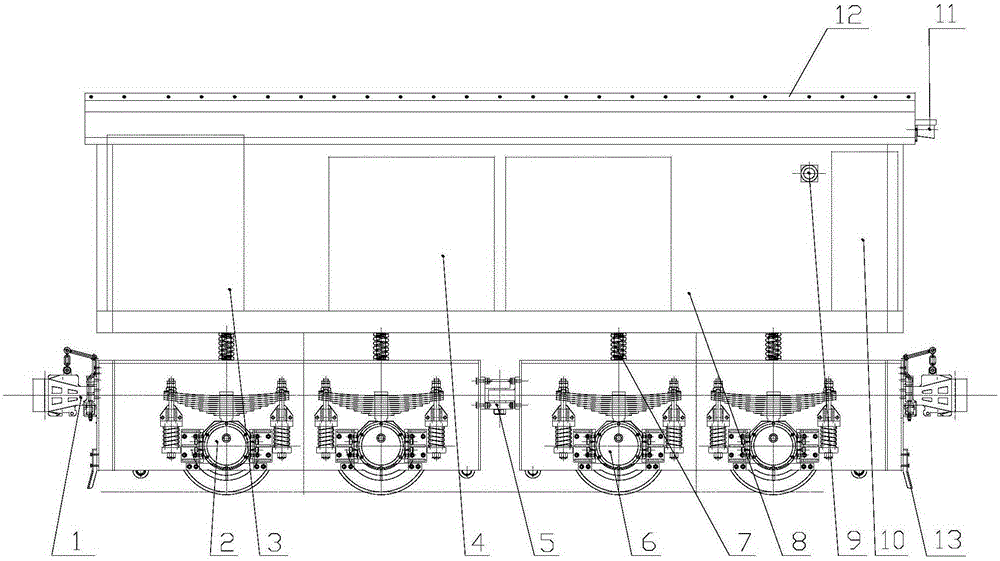

[0035] Such as Figure 1-Figure 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com