Power-generation and denitrification integrated device by residual heat of glass furnace and method thereof

A glass kiln, waste heat power generation technology, applied in chemical instruments and methods, separation methods, furnaces, etc., to achieve high denitration efficiency, reduce waste, and reduce volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation of the present invention is described below in conjunction with accompanying drawing:

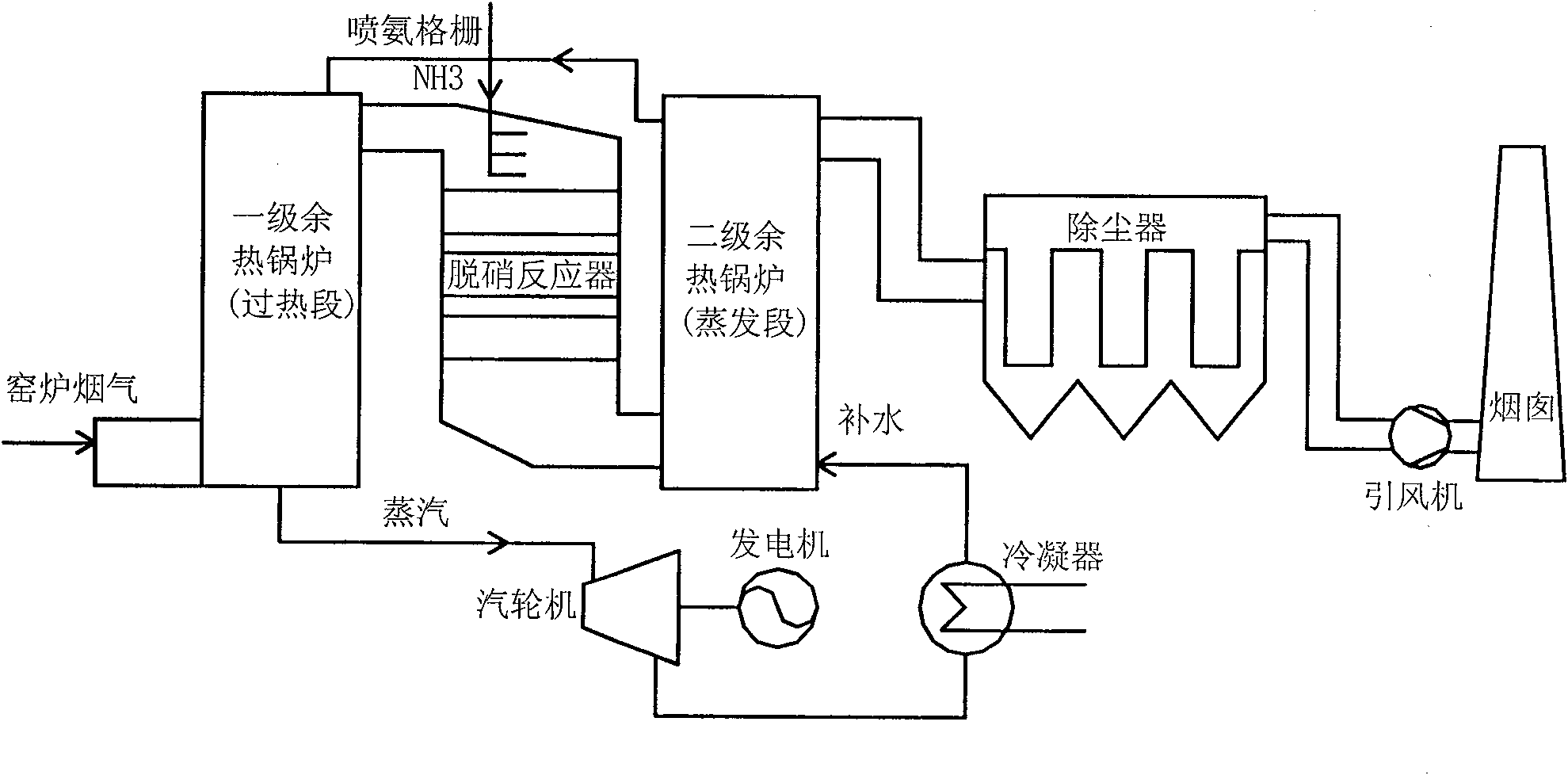

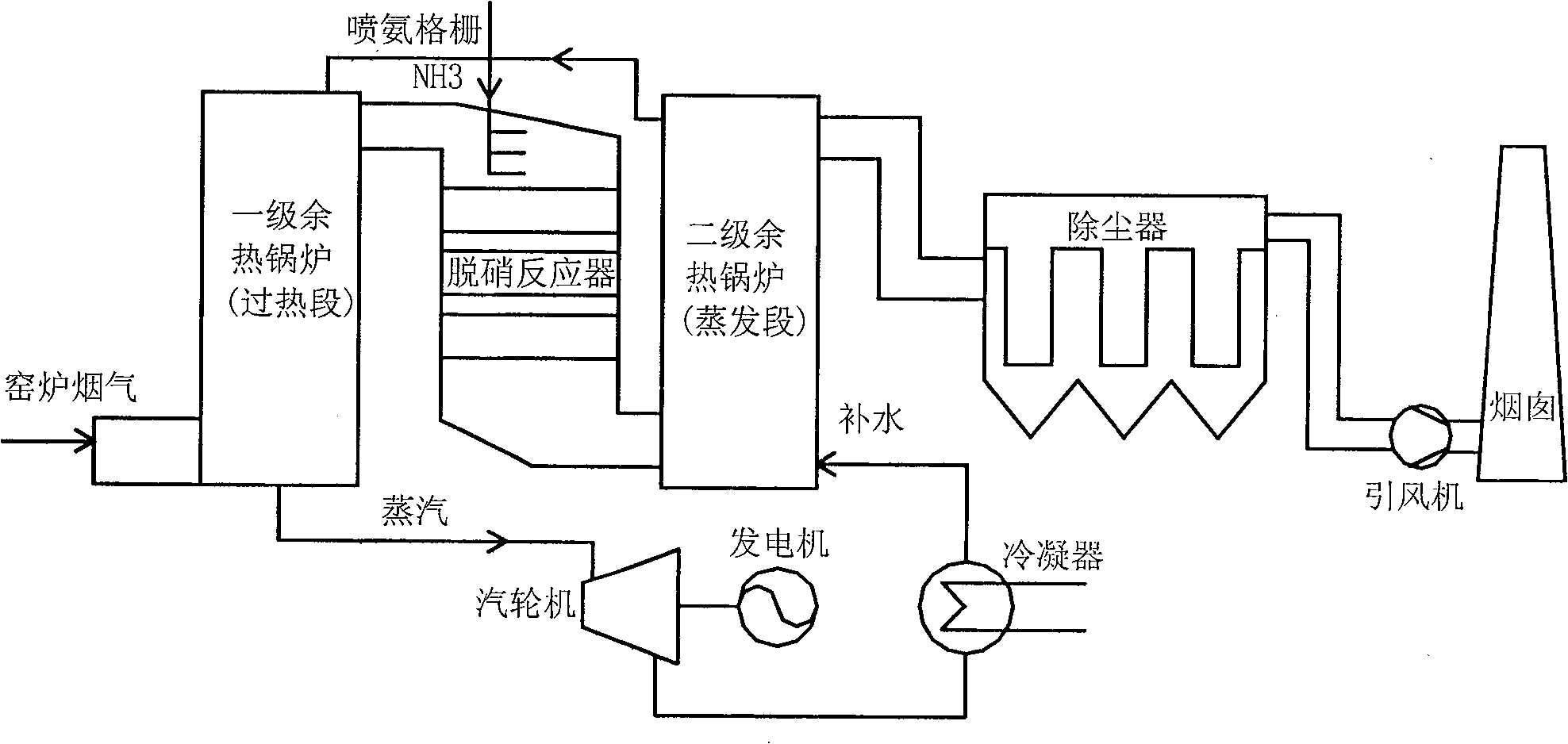

[0010] like figure 1 As shown, the flow of the integrated method of waste heat power generation and denitrification in glass kiln is as follows: the temperature of the flue gas from the glass kiln passes through the waste heat boiler, and then the temperature drops to 320-370 degrees, and then the flue gas passes through the medium temperature denitrification reaction device at a flow rate of 4-6m / s flue gas NO X denitrification reduction, the catalytic reaction temperature of medium temperature denitrification in this section is: 300-400 degrees, and the catalyst used in the reaction is a flat-plate catalyst V 2 o 5 / TiO 2 , The board spacing is 5-6mm. The reducing agent is liquid ammonia, and then the temperature is reduced to 150-200 degrees in the evaporation section of the waste heat boiler, then the bag dust is removed, and finally it is discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com