Patents

Literature

52results about How to "Does not affect power generation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

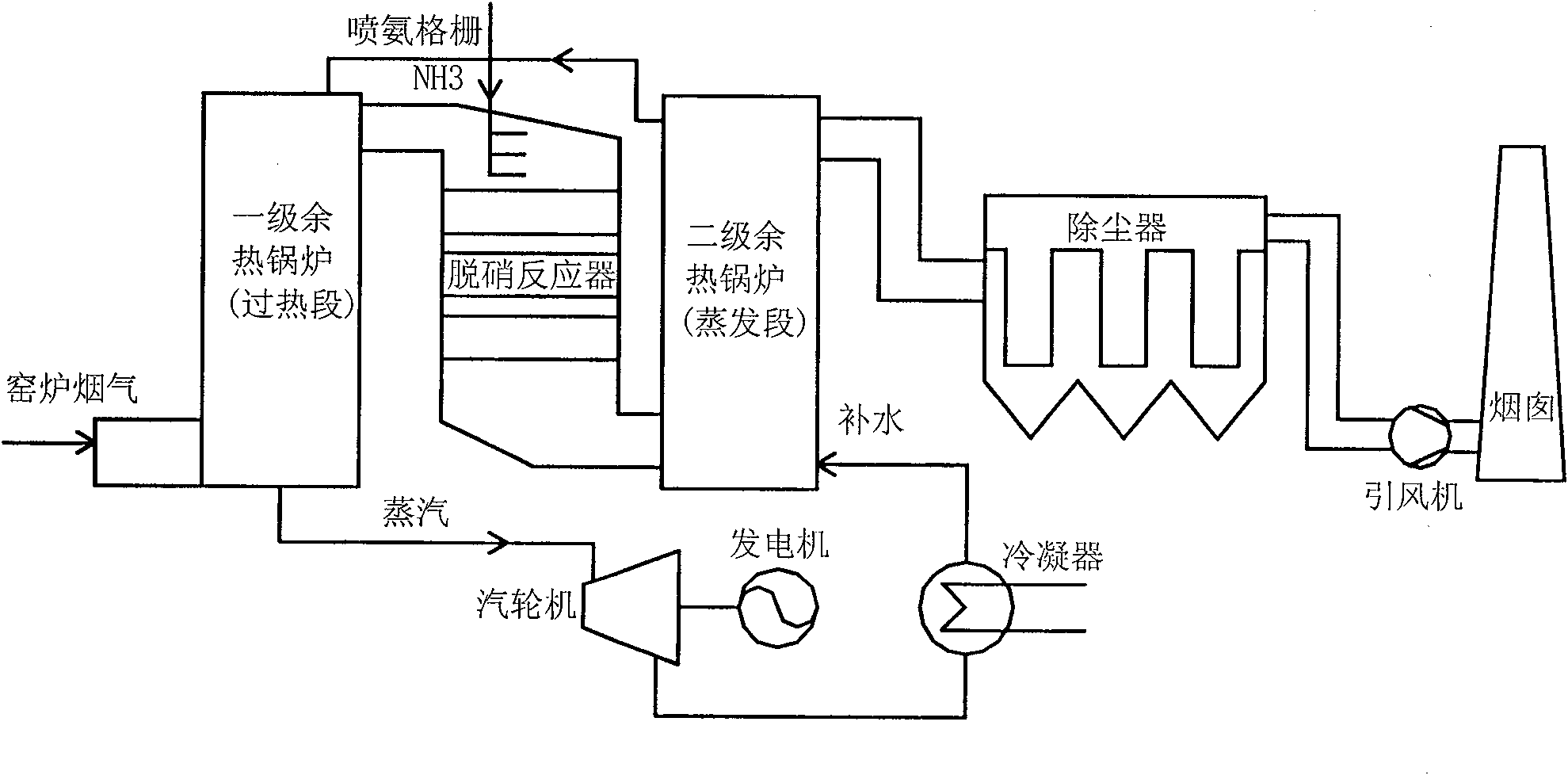

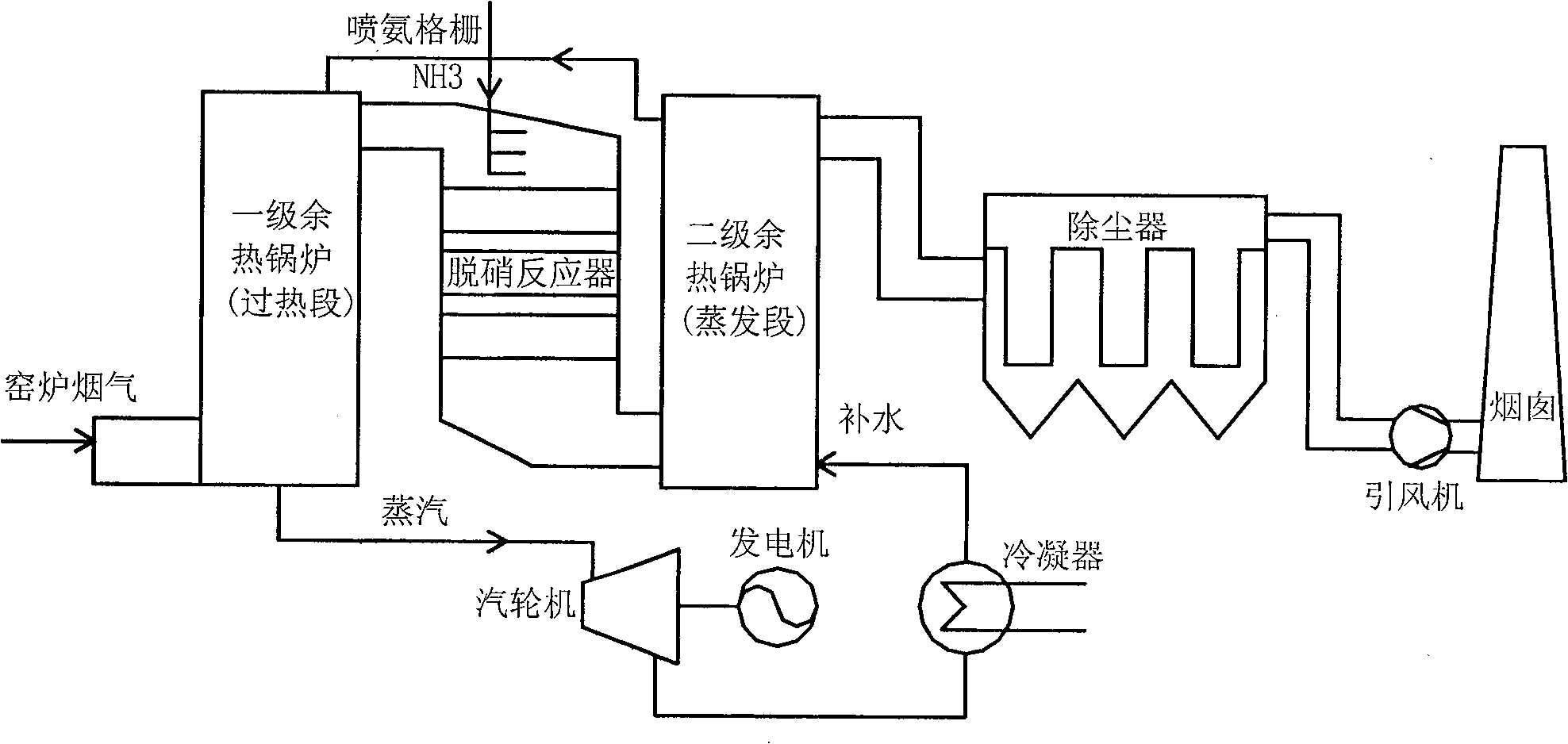

Power-generation and denitrification integrated device by residual heat of glass furnace and method thereof

InactiveCN101898086ASmall side effectsHigh activityDispersed particle filtrationIncreasing energy efficiencyGlass furnaceEvaporation

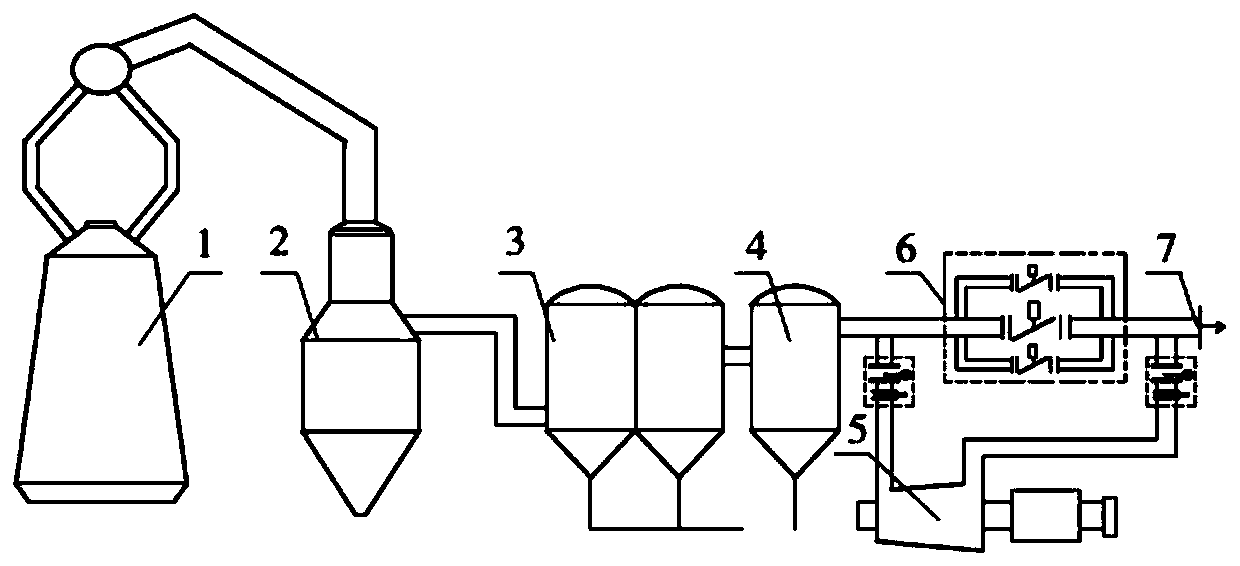

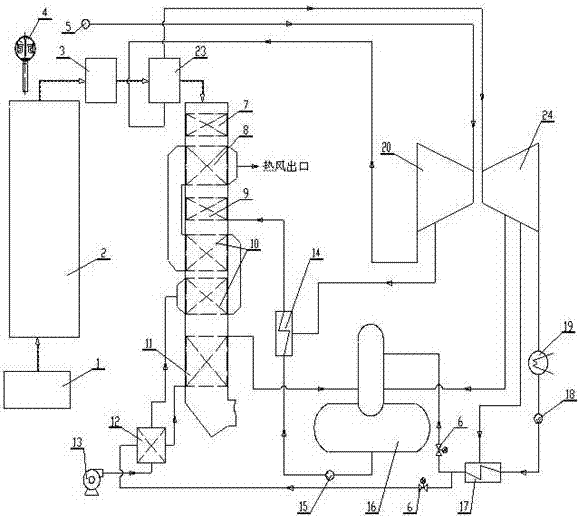

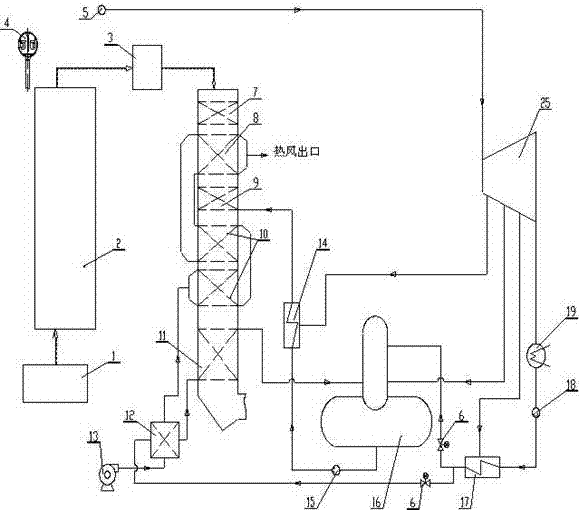

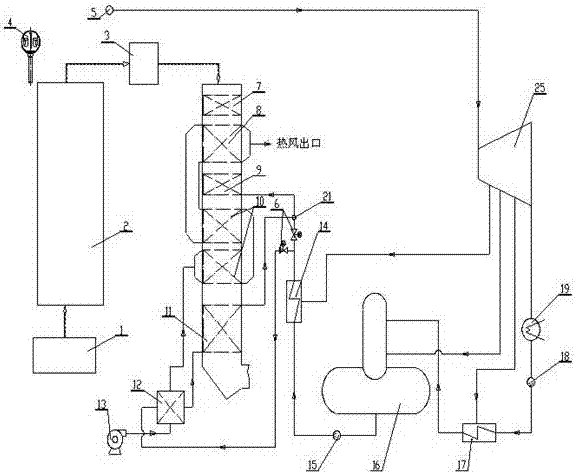

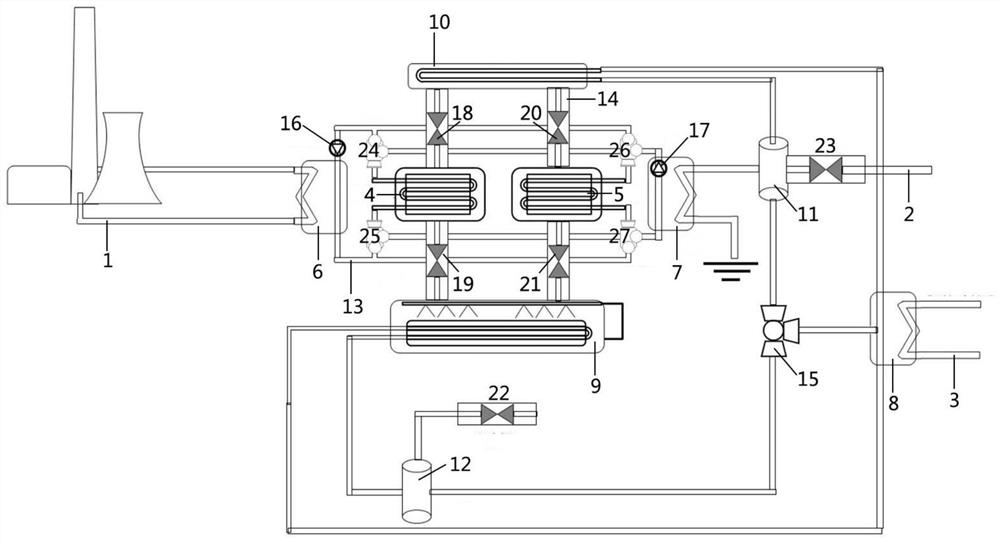

The invention provides a power-generation and denitrification integrated device by residual heat of a glass furnace and a method thereof, relating to the field of waste gas chemical purification treatment. Regarding NOX in large-output volume continuous flue gas in flat glass industry, SCR and SNCR technologies are adopted currently. SCR has the problems of large equipment investment, high technical difficulty, residual heat waste and the like, while SNCR has a large NH3 usage amount, is hard to ensure reacting temperature and staying time, can easily cause secondary pollution, and has low denitrification efficiency. Aiming at the problems and being different from hot topic studying directions, such as high-performance low-temperature denitrification catalyst, additive and the like, the invention discloses the power-generation and denitrification integrated device by the residual heat of the glass furnace and the method thereof, wherein a denitrification system is arranged between the overheat section and an evaporation section of the residual heat boiler; the temperature of the flue gas is cooled to a medium temperature range by using the overheat section of the primary residual heat boiler; and the flue gas performs a catalytic reduction with a reducing agent NH3 in a reactor under the action of a catalyst V2O5 / TiO2 to generate non-polluted N2 and H2O, and the temperature of denitrification and catalysis is between 300 and 400 DEG C.

Owner:无锡迅德环保科技有限公司

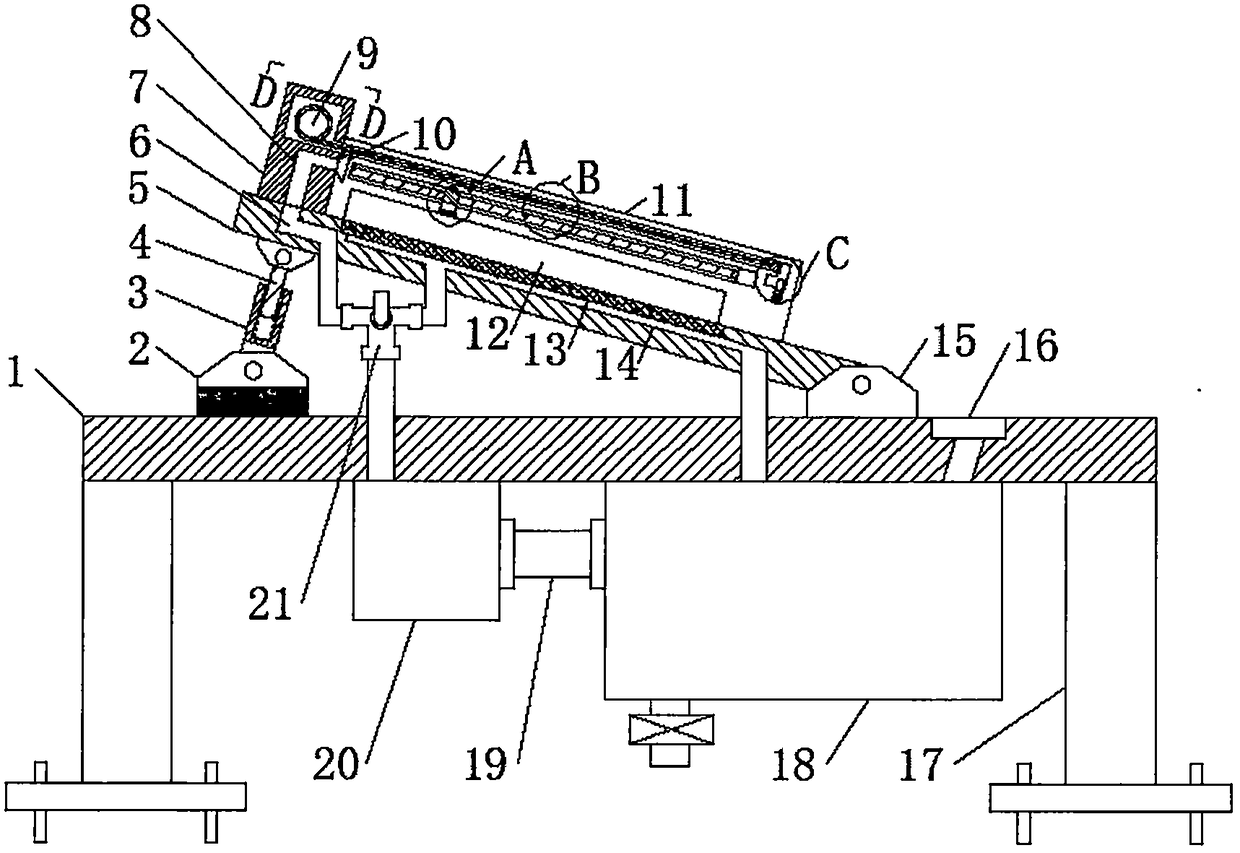

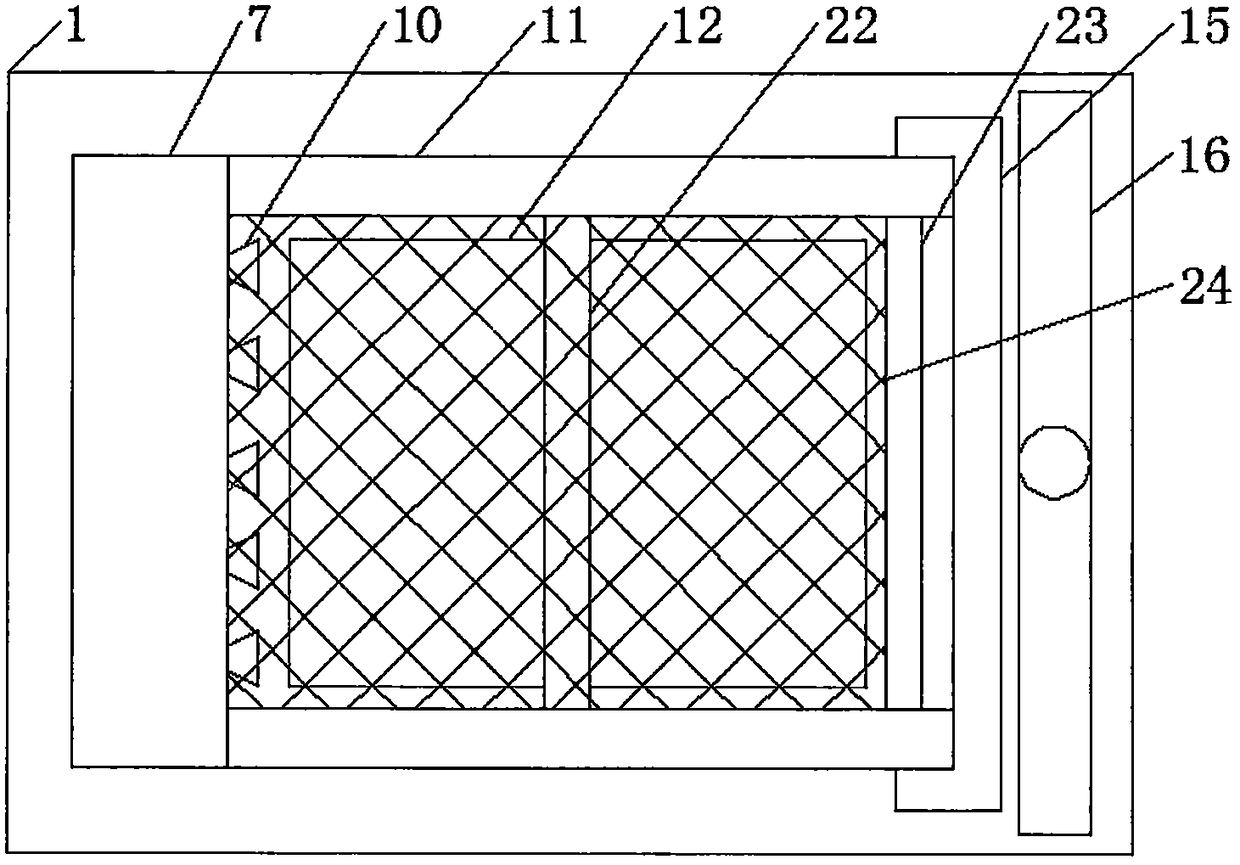

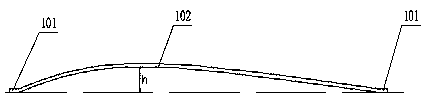

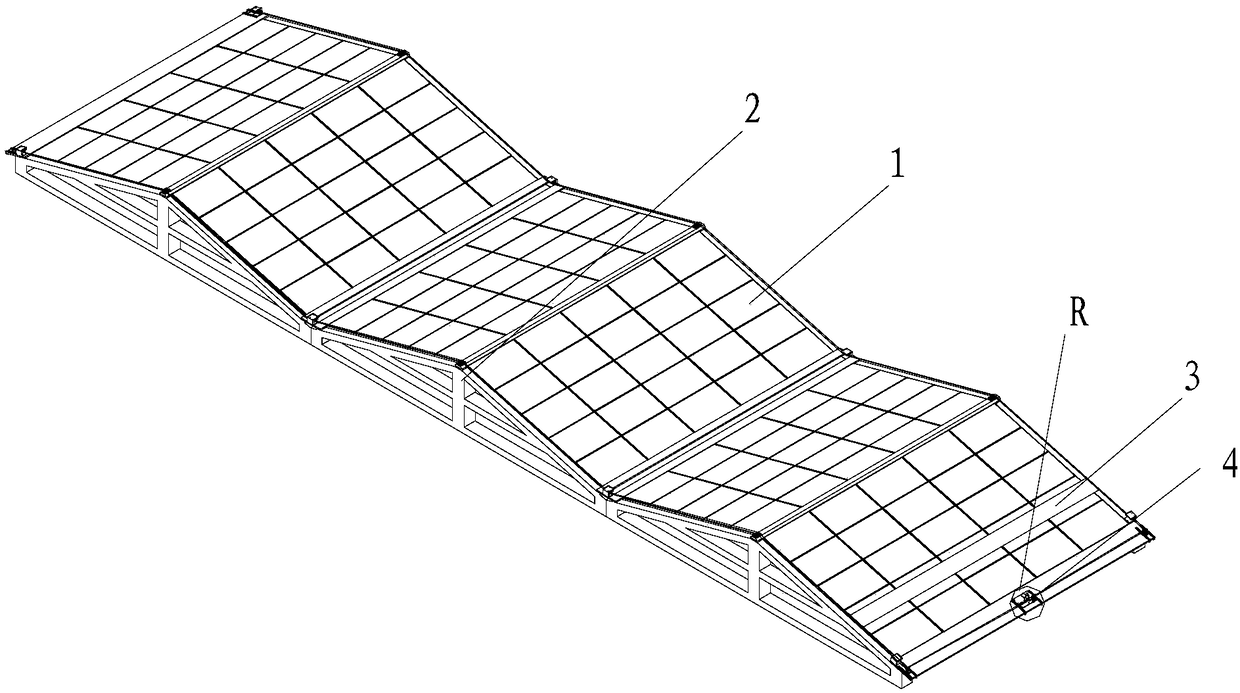

Protection device for photovoltaic power generation solar cell panel

ActiveCN108923742AAvoid damageDoes not affect power generation efficiencyPhotovoltaicsCleaning using toolsCells panelEngineering

The invention discloses a protection device for a photovoltaic power generation solar cell panel. The protection device comprises a base; a first support is fixedly connected to the edge of the top ofthe base; the inner wall of the first support is connected with a mounting plated in a hinged mode through a hinge; the bottom, away from the first support, of the mounting plate is rotatably connected with an adjusting mechanism through a hinge; a second support is hinged to the bottom of the adjusting mechanism through a hinge; the bottom of the second support is fixedly connected with a rubbergasket; the bottom of the rubber gasket is fixedly connected with the top of the base; the end, close to the adjusting mechanism, of the top of the mounting plate is fixedly connected with a mountingblock; two parallel fixing plates are fixedly connected to the side, close to the first support, of the mounting block; the bottoms of the two fixing plates are both fixedly connected with the top ofthe mounting plate; and the top of the mounting plate is fixedly connected with a cell panel body. According to the protection device, the purpose of preventing the solar cell panel from being proneto damage or affecting power generation efficiency is achieved through the arrangement of a protection net and the cooling and cleaning effects of water in a water tank.

Owner:JIAXING UNIV

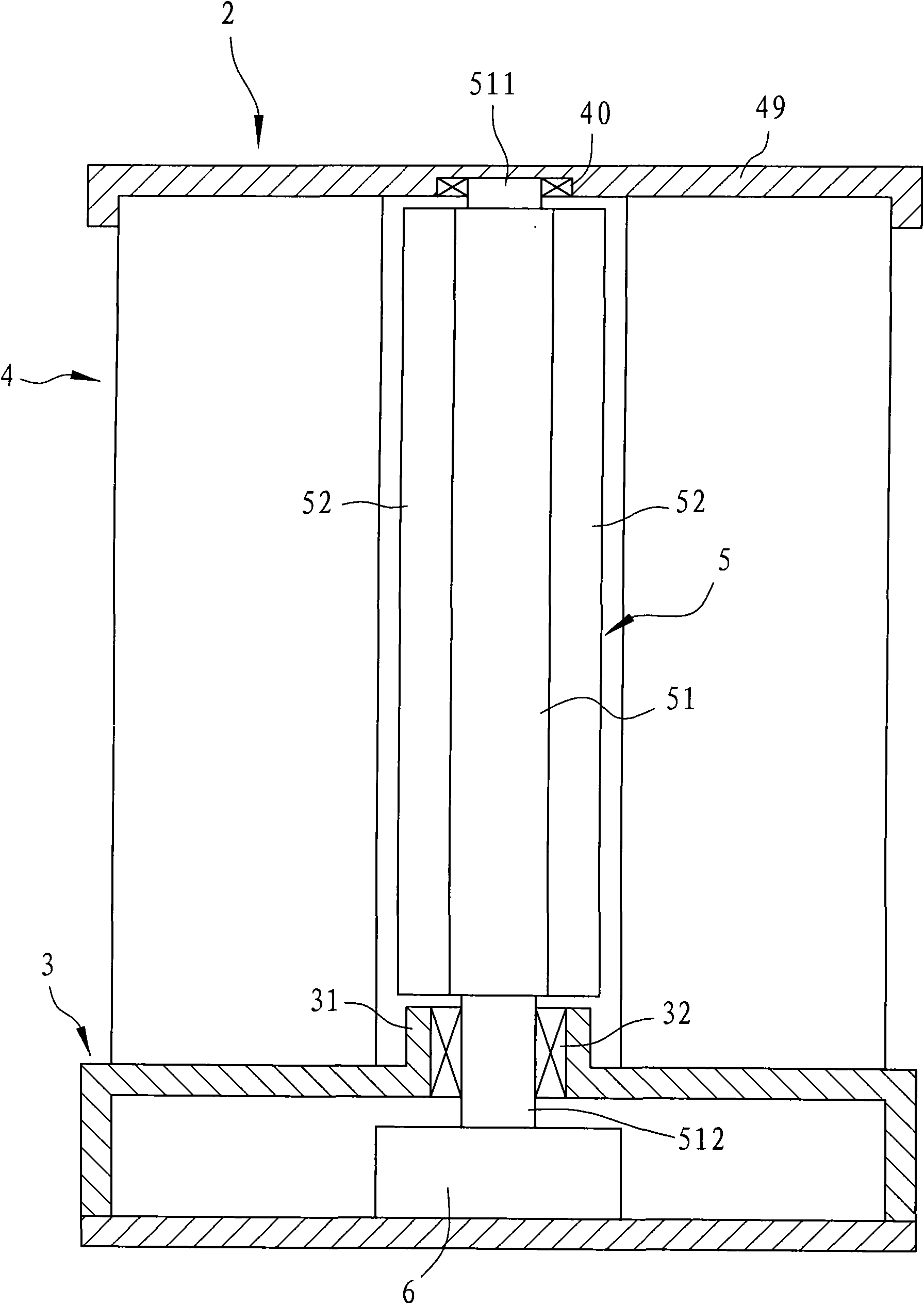

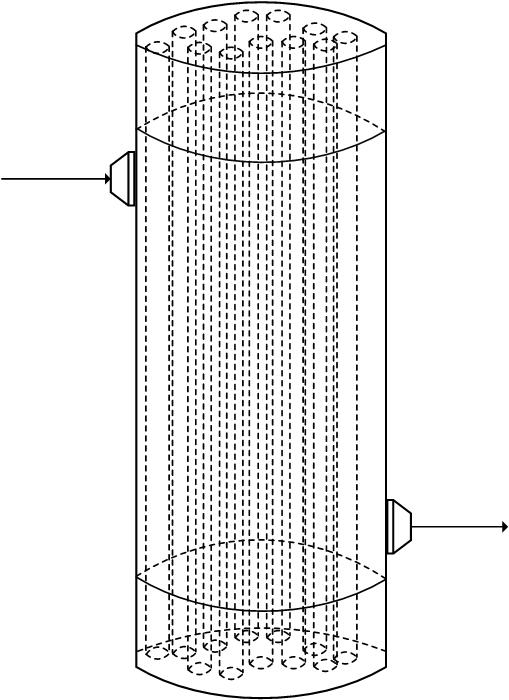

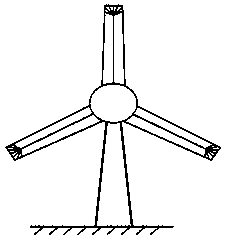

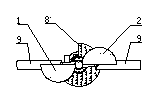

Novel parallel multidimensional oscillating sea wave power generation device

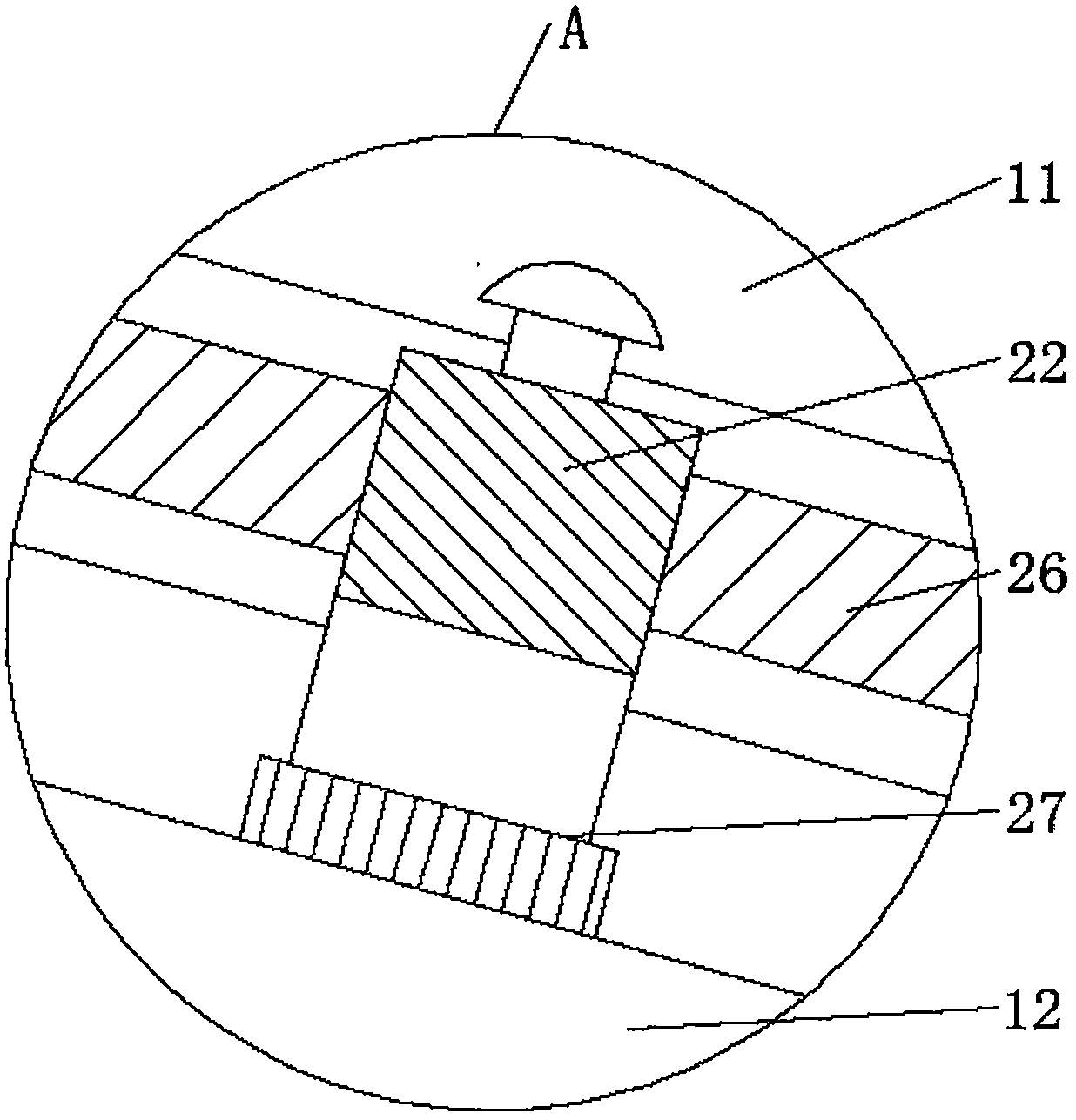

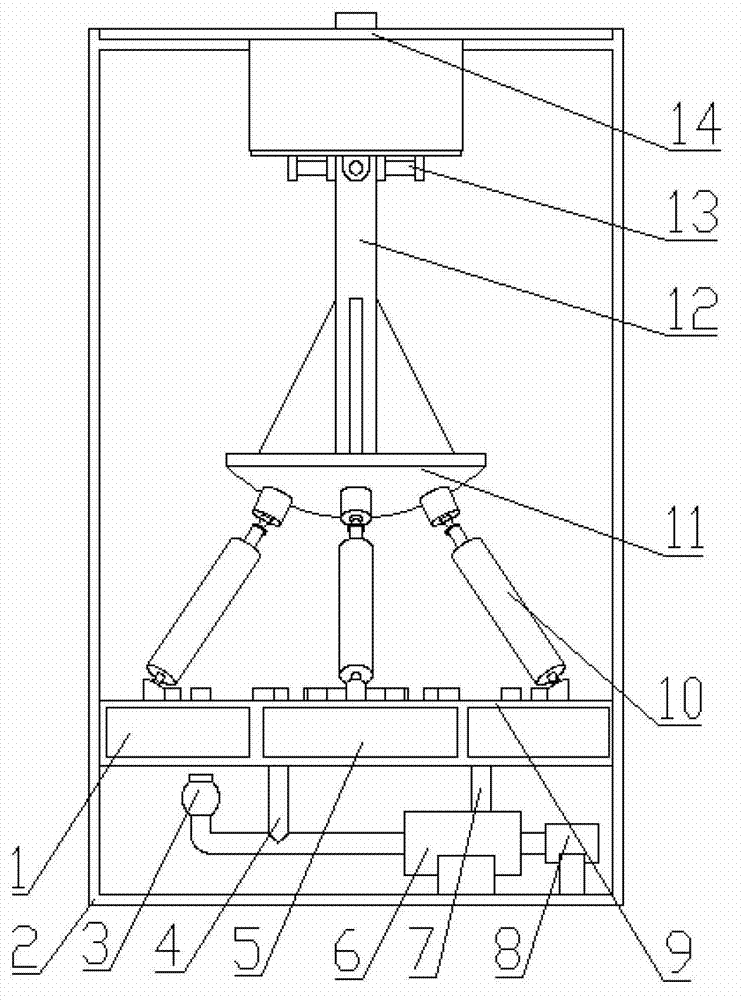

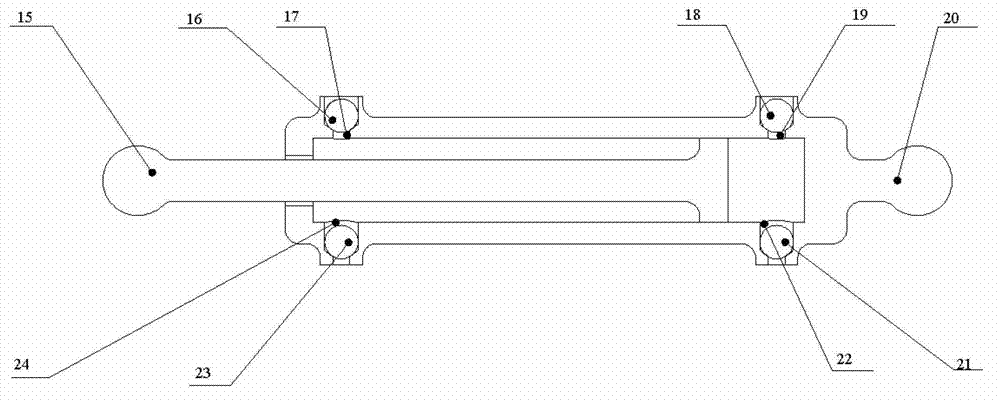

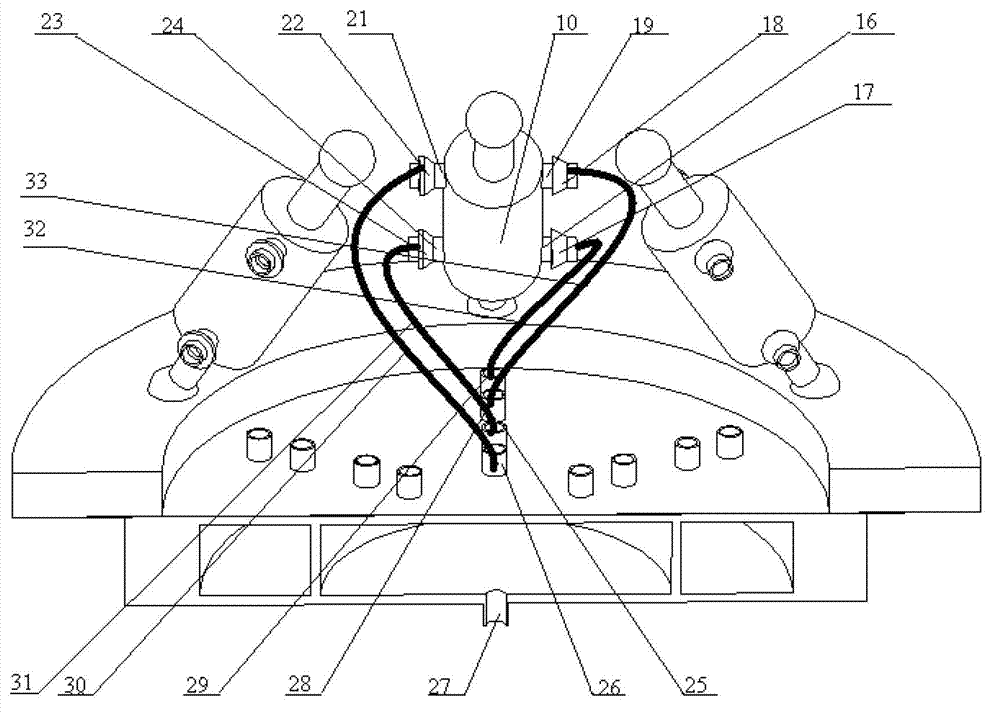

InactiveCN103306882AImprove sealingReduced risk of corrosionMachines/enginesEngine componentsHydraulic motorHydraulic cylinder

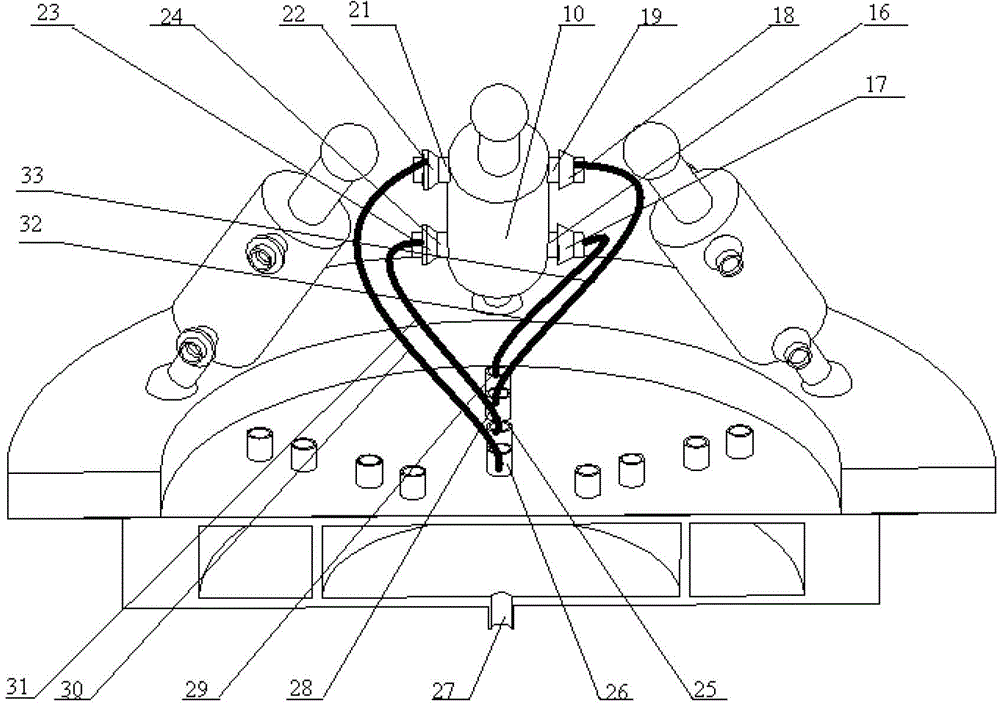

The invention discloses a novel parallel multidimensional oscillating sea wave power generation device. The novel parallel multidimensional oscillating sea wave power generation device comprises a floater, and a sealing cover plate, a two-dimensional rotating hinge, an oscillating rod, an oscillating platform, six hydraulic cylinders, an oil tank, a hydraulic motor, a power generator and an energy accumulator which are all arranged in the floater, wherein the sealing cover plate is fixedly connected to a protruding eave of the floater; the oil tank is fixedly connected to the floater; one end of the two-dimensional rotating hinge is fixedly connected to the sealing cover plate and the other end is connected to the oscillating rod; one end of the oscillating rod penetrates through the sealing cover plate to be fixedly connected to an external device and the other end is fixedly connected to the oscillating platform; the six hydraulic cylinders are connected in parallel to work; the two ends of the six hydraulic cylinders are respectively hinged to the oscillating platform and the oil tank through spherical hinges; the oil tank is connected with the hydraulic motor through a flow-dividing pipe and a return pipe; the power generator is connected with the hydraulic motor; the power generator and the hydraulic motor are arranged on the bottom surface of the floater; the energy accumulator is connected with the hydraulic motor. The novel parallel multidimensional oscillating sea wave power generation device has the advantages of long service life, low maintenance cost, low environmental pollution, capability of fully absorbing sea wave energy, high power generation efficiency and the like.

Owner:SHANGHAI JIAO TONG UNIV

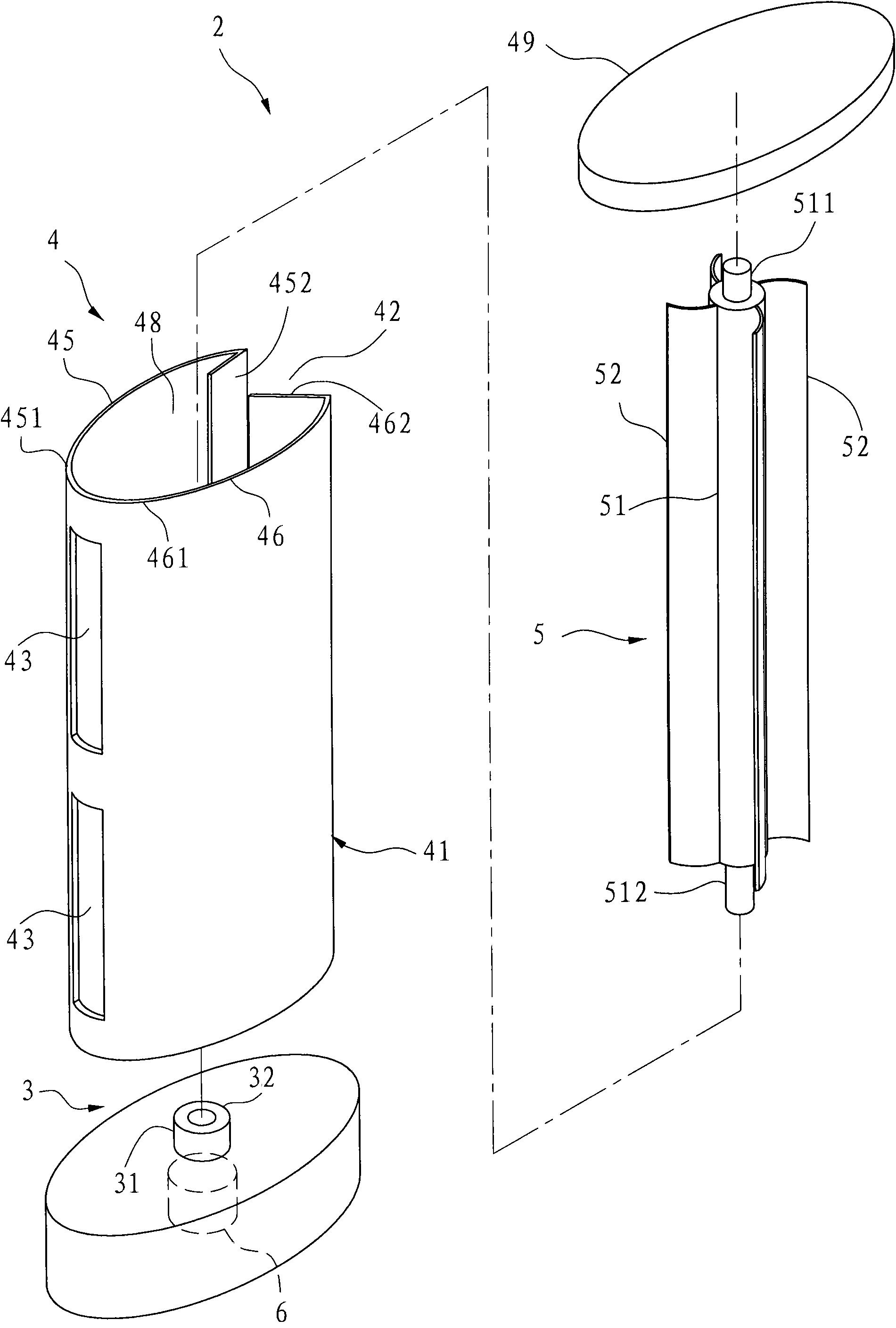

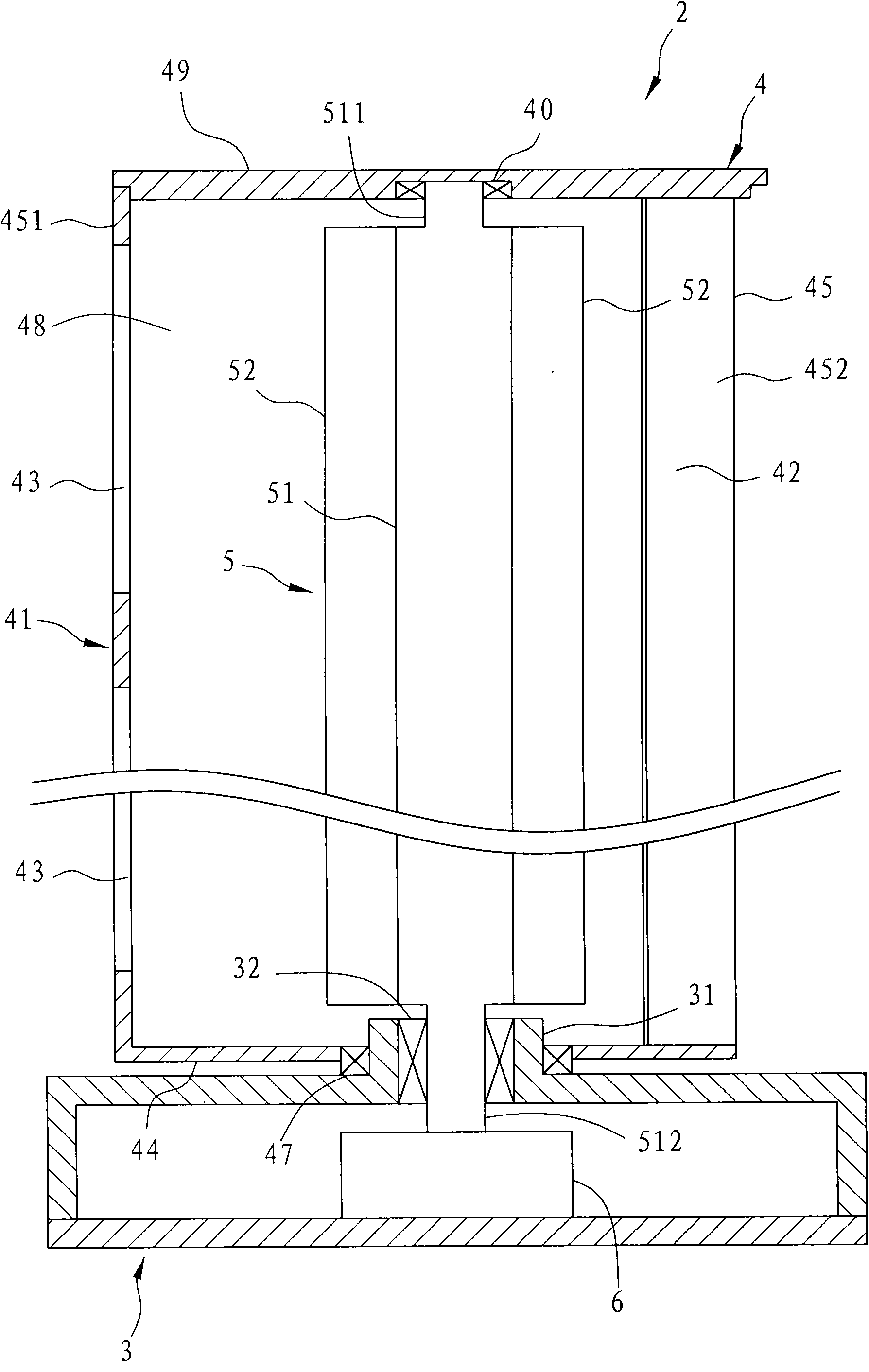

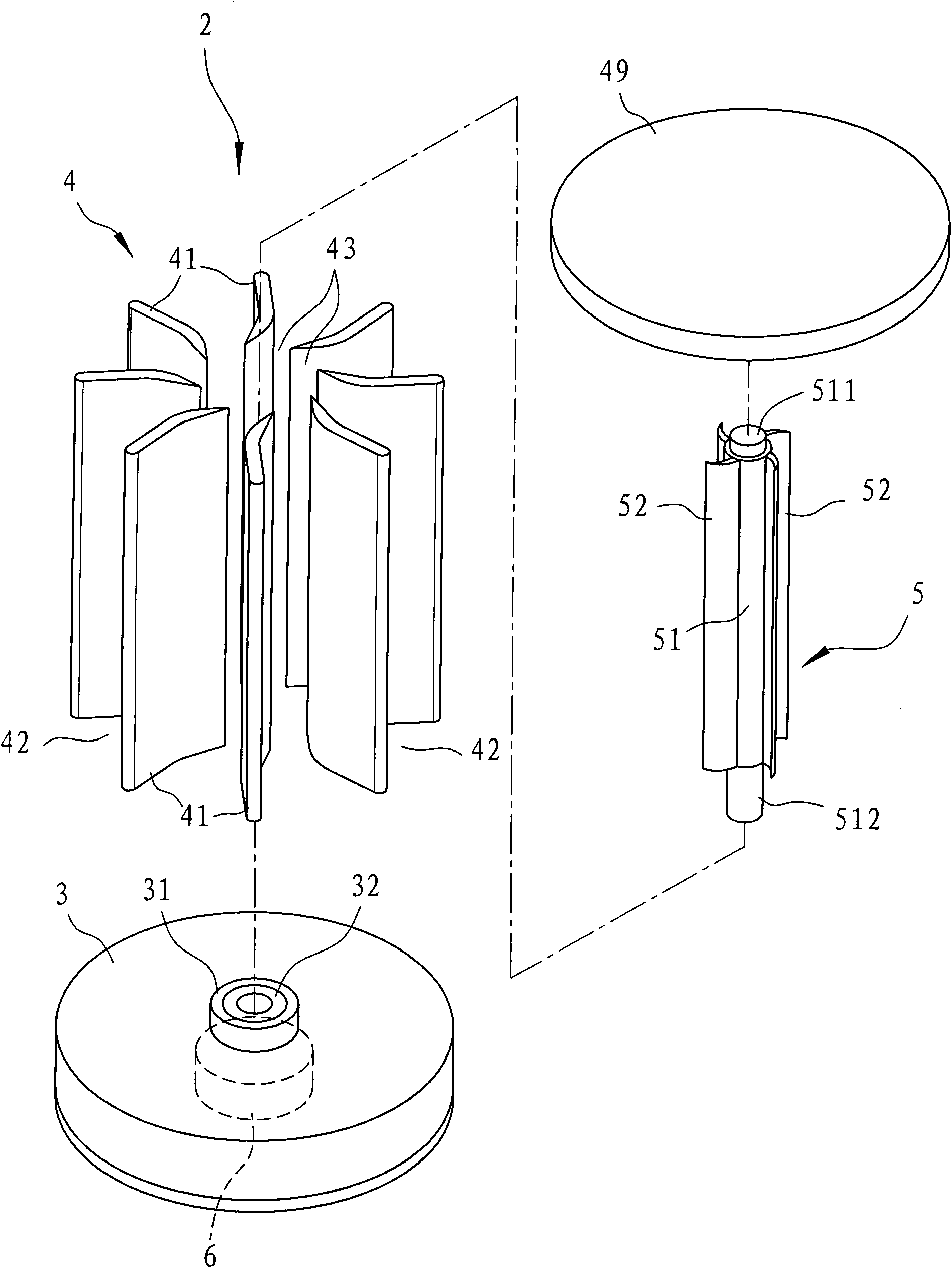

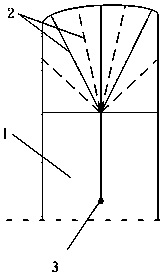

Power generating device capable of collecting wind along wind direction

ActiveCN101555866AReduce volumeShorten the lengthWind motor combinationsMachines/enginesEngineeringWind force

The invention relates to a power generating device capable of collecting wind along wind direction, comprising a base, a power generating unit and a rotary unit; the power generating unit is arranged in the base; the rotary unit is connected with the power generating unit and is protruded on the base; the rotary unit is provided with a rotary shaft, a plurality of fan leaves and a wind collecting cover, wherein the rotary shaft drives the power generating unit, the wind collecting cover is pivoted on the base, is covered on the rotary shaft and the fan leaves of the rotary unit and can rotate relative to the base; the wind collecting cover is provided with a cover body, at least one of wind inlets disposed on the cover body and at least one of wind outlets disposed on the cover body and corresponding to the wind inlets; the caliber of each wind inlet is larger than that of each wind outlet; and when wind force is led into the wind collecting cover, the wind force can drive each fan leaf of the rotary unit to link the rotary shaft to rotate in a fixed direction. Because the wind collecting cover is pivoted on the base, when the wind collecting cover is blown by the wind force, the wind inlets of the wind collecting cover can continuously face the strongest wind direction, so that the fan leaves of the rotary unit can be continuously blown by the wind force. The invention can stabilize the benefit of wind power generation and reduce the integral volume of the power generating device under the condition of not influencing the benefit of wind power generation.

Owner:林碧霞

Power generation device capable of collecting wind in many directions

ActiveCN101566124AReduce volumeShorten the lengthWind motor combinationsMachines/enginesWind forceEngineering

The invention relates to a power generation device capable of collecting wind in many directions, which comprises a base, a power generation unit arranged in the base, a rotating unit and a wind collecting unit which is arranged on the base and surrounds the rotating unit, wherein the wind collecting unit comprises a plurality of vertical wind collecting plates which are arranged radially at intervals; the outer edges of two adjacent wind collecting plates are matched with each other to form a wind inlet, and the inner edges of two adjacent wind collecting plates are matched with each other to form a wind collecting port; and the rotating unit is provided with a rotating shaft and a plurality of vanes, wherein the rotating shaft can be driven to rotate by wind force to drive the power generation unit, and the vanes extend outwards from the rotating shaft. When the wind collecting unit is blown by wind force from different directions, the wind can be introduced from the wind inlet corresponding to the wind direction to collect the wind force, and thus, the vanes of the rotating unit can be continuously blown by the wind force to stabilize the benefit of wind power generation.

Owner:林碧霞

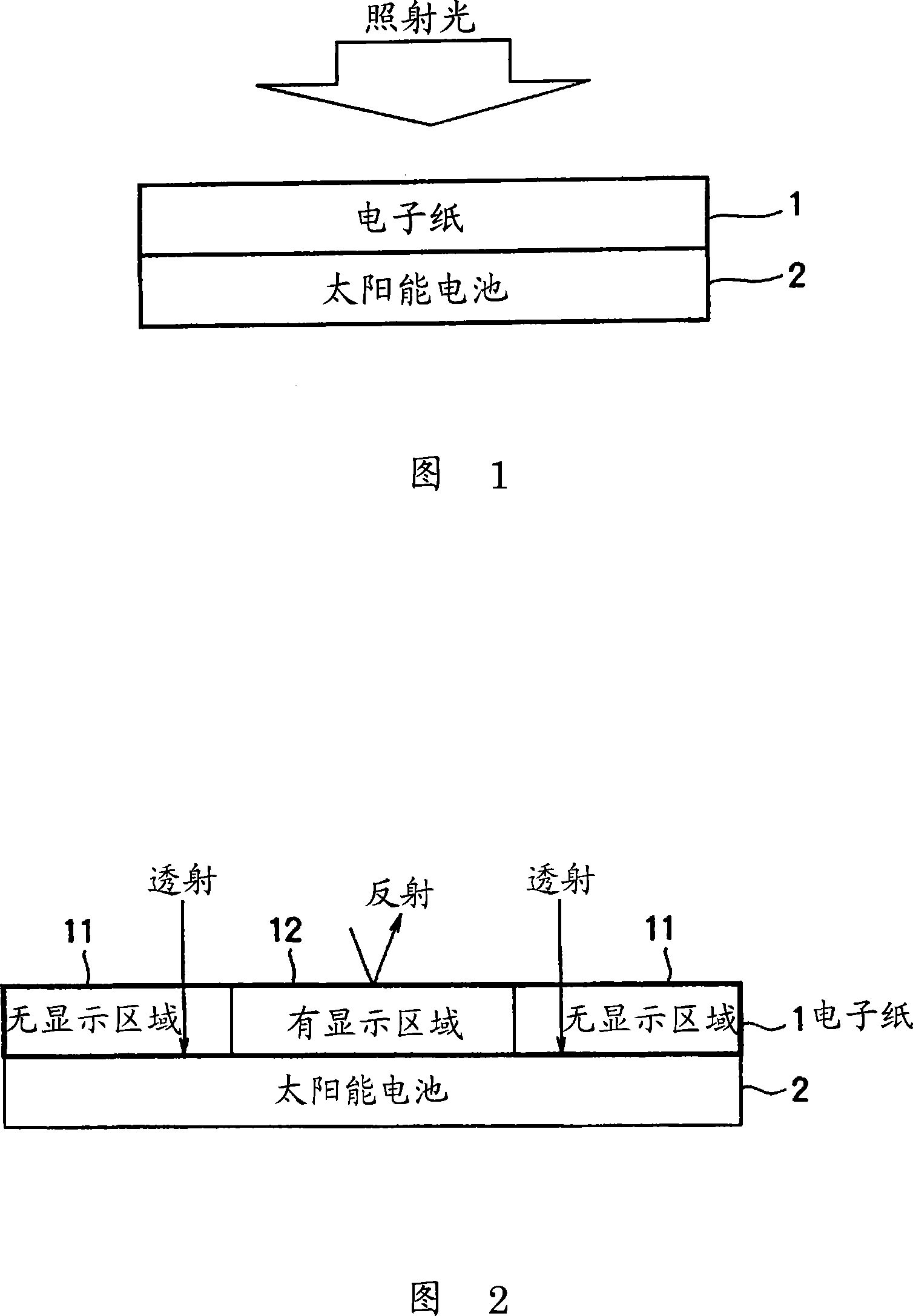

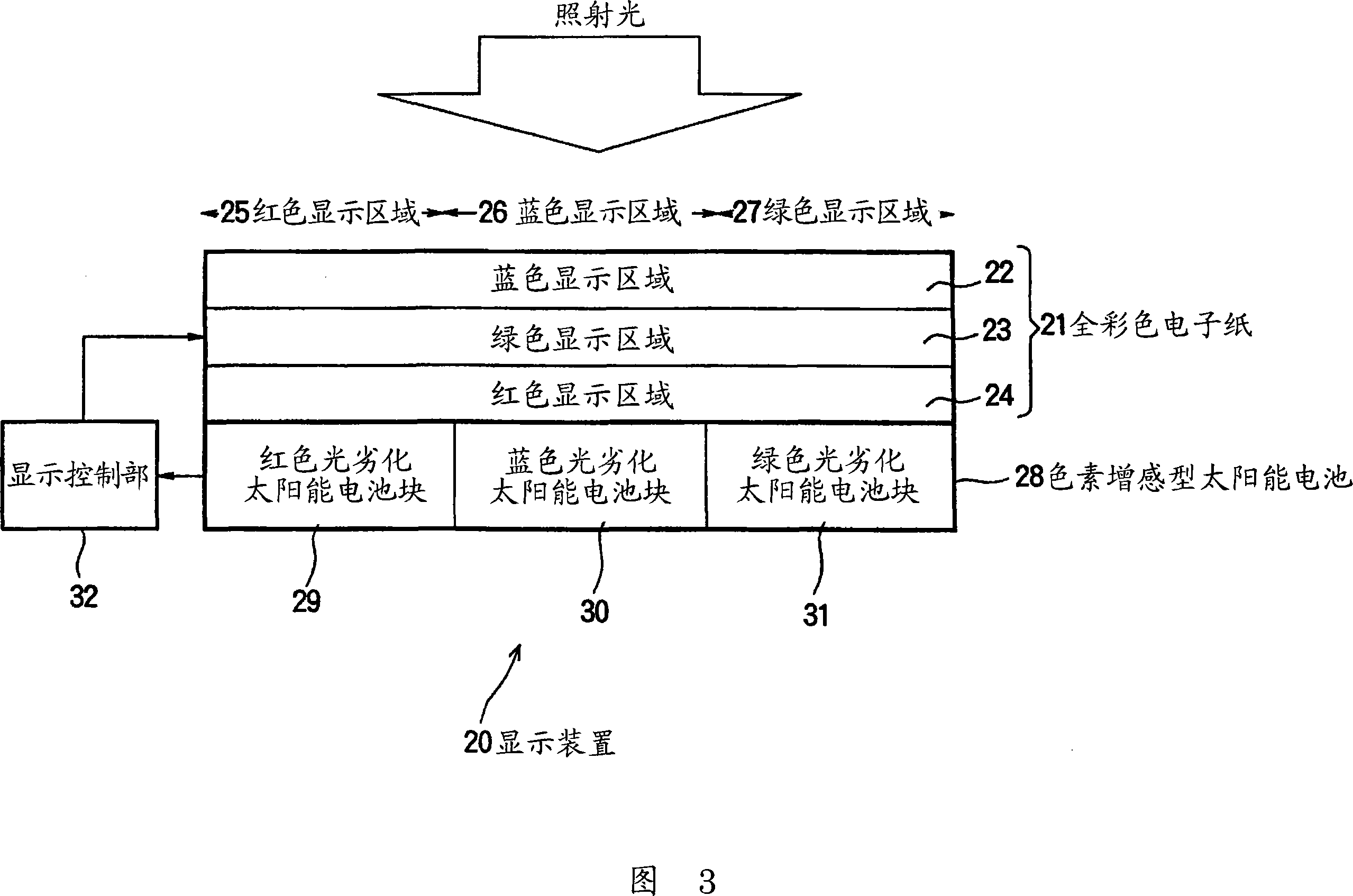

Electronic device

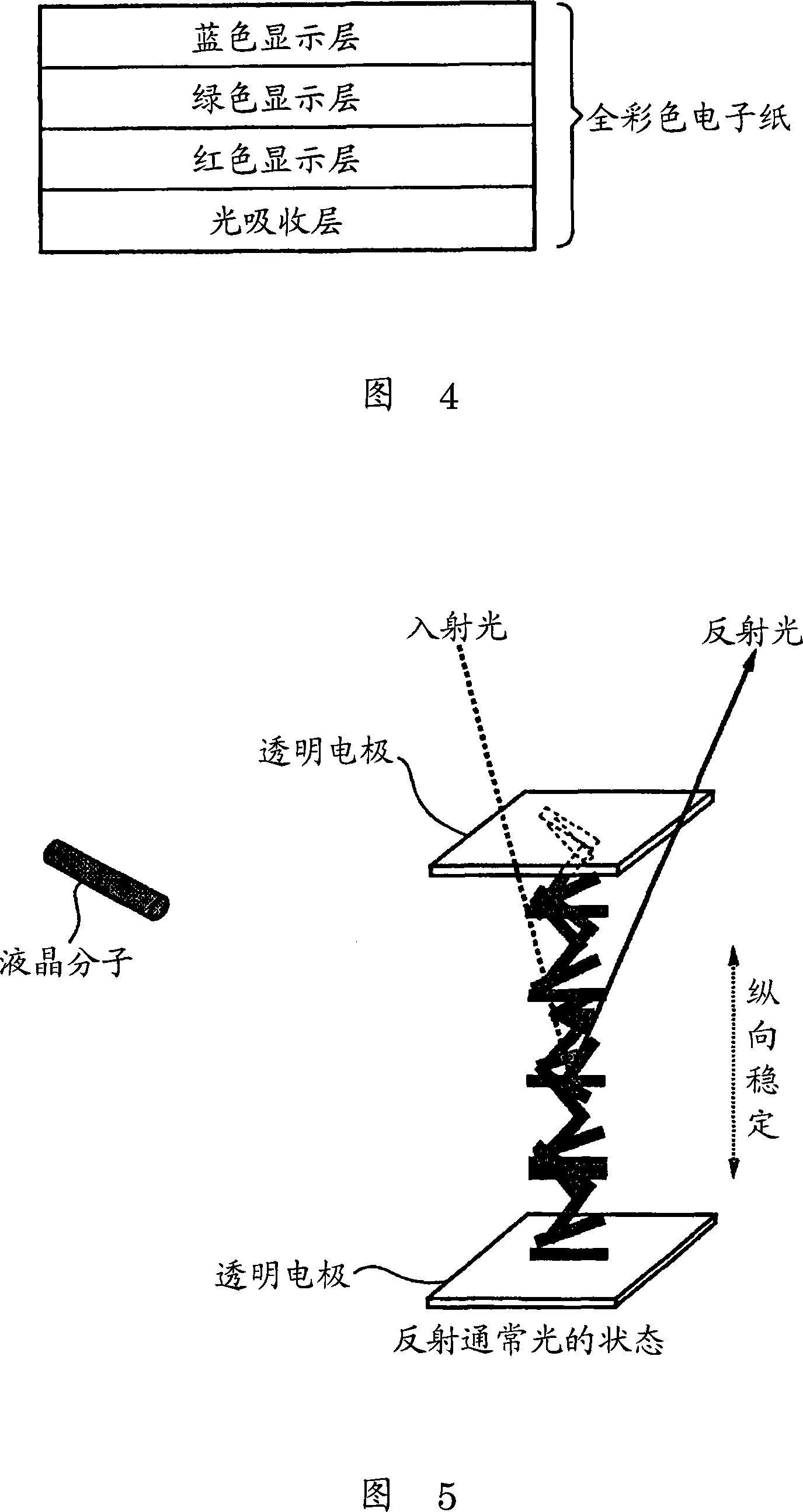

InactiveCN101122689ADoes not affect power generation efficiencyStatic indicating devicesRecord carriers used with machinesElectrical batteryDisplay device

The present invention provides an electric device. In the device the display and the solar battery are stacked while the displaying content of the display does not affect the generating efficiency of the solar battery. The light which transmits full-color electronic paper (21) except for the red light is always irradiated to the red light deteriorating solar battery block (29) of the dye-sensitized solar cell (28). Otherwise, the light which transmits full-color electronic paper (21) except for the blue light is always irradiated to the blue light deteriorating solar battery block (30). Besides, the light which transmits full-color electronic paper (21) except for the green light is always irradiated to the green light deteriorating solar battery block (31). The invention can be used for the IC card or the small-sized electronic device.

Owner:SONY GRP CORP

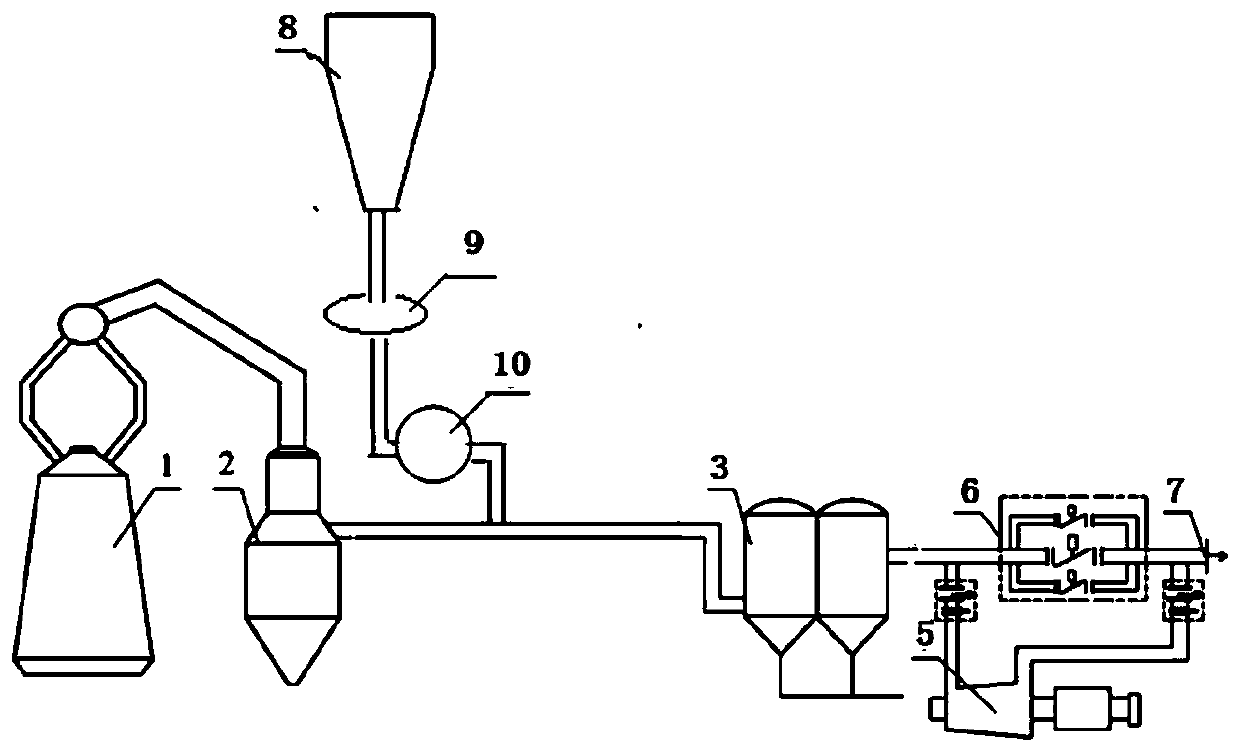

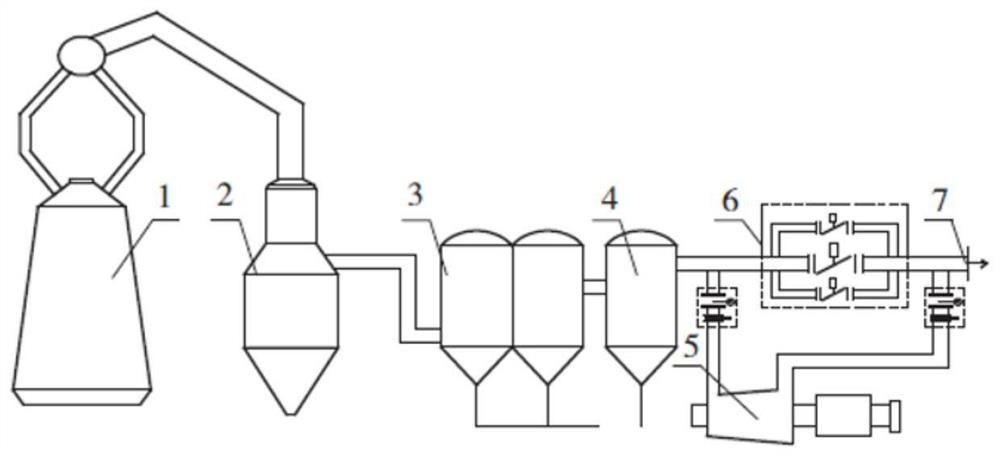

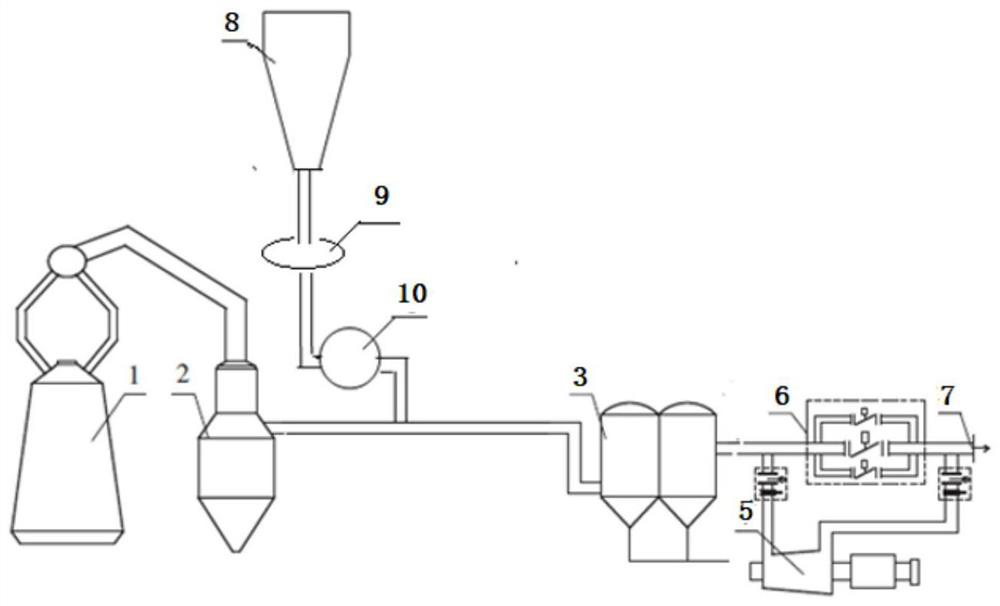

Technological method of removing hydrogen chloride through powder injection of blast furnace gas pipeline and device of removing hydrogen chloride through powder injection of blast furnace gas pipeline

ActiveCN111378801AImprove uniformityImprove sufficiencyBlast furnace detailsIncreasing energy efficiencyChemistryPulverizer

The invention discloses a technological method of removing hydrogen chloride through powder injection of a blast furnace gas pipeline and a device of removing hydrogen chloride through powder injection of the blast furnace gas pipeline. The device utilizing the technology of adopting blast furnace gas pipeline powder injection to remove hydrogen chloride adopts the dry type blast furnace gas injecting dechloridation technology to remove hydrogen chloride; a dechlorination agent bag-type dust collector hopper, a pulverizer and a draught fan are sequentially mounted on a pipeline behind a dry process coarse dust remover and in front of the bag-type dust collector of the existing device; and the condition of blast furnace gas in an outlet pipeline of the dry process coarse dust remover is set; through grinding, the dechlorination agent obtains a larger specific surface area, and the ground dechlorination agent is directly injected in the blast furnace gas pipeline for dechloridation reaction through the powder injection manner. With adoption of the technical scheme, the one-time investment is less, the occupied area is small, and the system is simple in operation and convenient to maintain. The technology can effectively improve the contact uniformity and sufficiency of the dechlorination agent and blast furnace gas, improves the dry process dechlorination effect, is low in heat loss of blast furnace gas and does not affect later application of TRT.

Owner:BEIJING PEKING UNIV PIONEER TECH

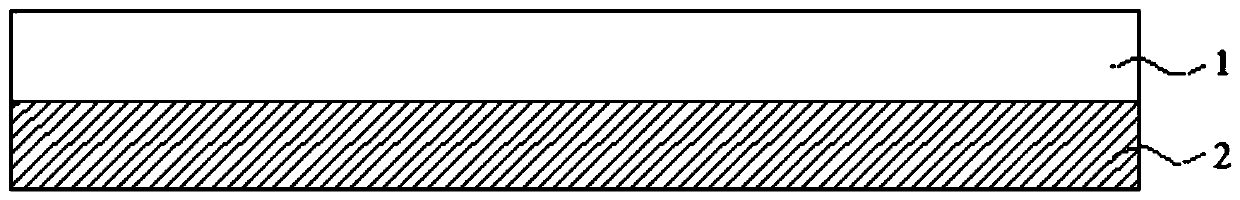

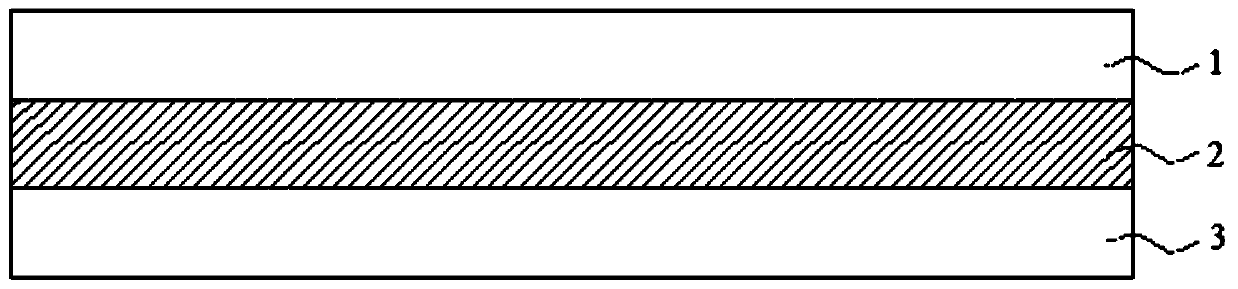

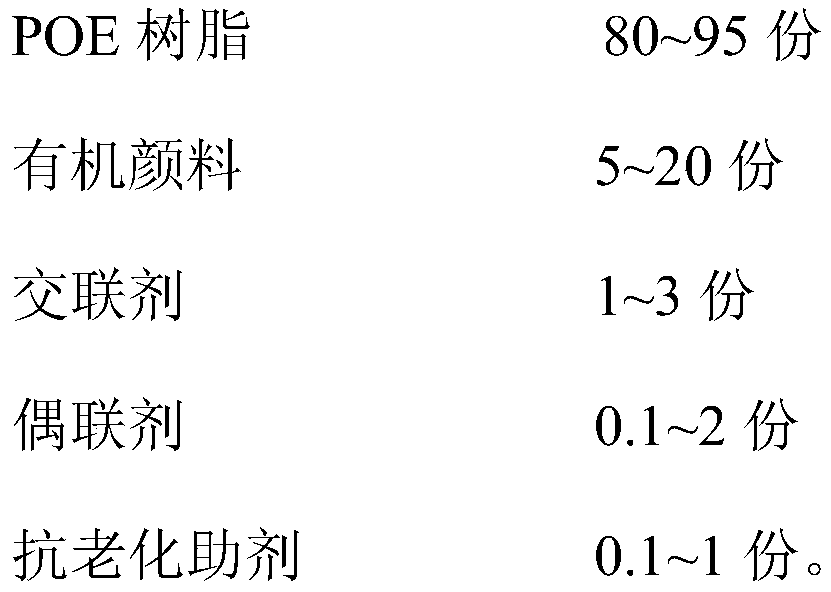

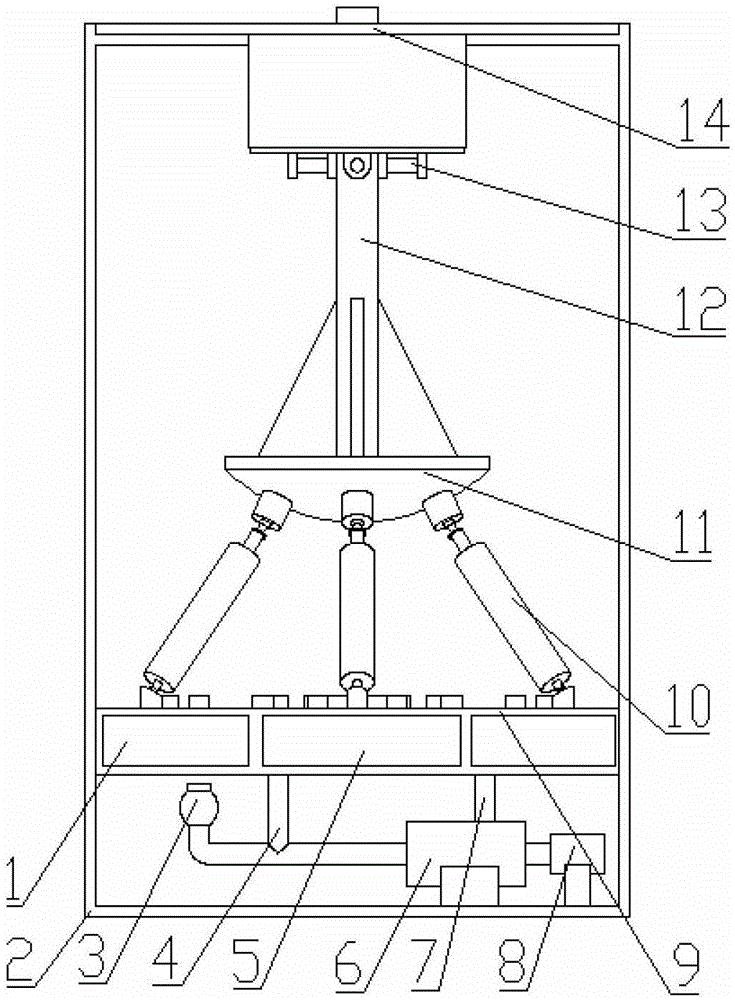

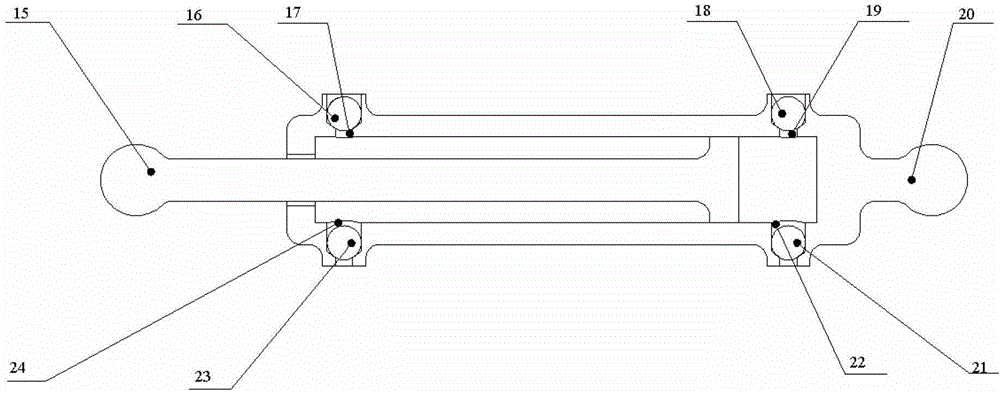

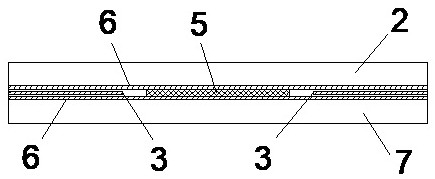

Colored packaging adhesive film with long-term fadeless performance and preparing method thereof

PendingCN109796909ADoes not affect power generation efficiencyImprove power generation efficiencyNon-macromolecular adhesive additivesFilm/foil adhesives without carriersAdhesiveEngineering

The invention provides a colored packaging adhesive film with long-term fadeless performance and a preparing method thereof. The colored packaging adhesive film with long-term fadeless performance comprises a colored layer and a transparent layer, wherein the transparent layer is arranged on at least one side of the colored layer and comprises a UV light absorber, and the colored layer contains organic pigment. The preparing method of the colored packaging adhesive film with long-term fadeless performance is simple, the prepared colored adhesive film is fadeless for a long term, and besides, acolored assembly prepared by means of the colored packaging adhesive film does not influence the power generation efficiency, and the colored packaging adhesive film is suitable for being used outdoors for a long term.

Owner:CYBRID TECHNOLOGIES INC

Parallel multi-dimensional swing wave power generation device

InactiveCN103306882BImprove sealingReduced risk of corrosionMachines/enginesEngine componentsHydraulic cylinderHydraulic motor

The invention discloses a novel parallel multidimensional oscillating sea wave power generation device. The novel parallel multidimensional oscillating sea wave power generation device comprises a floater, and a sealing cover plate, a two-dimensional rotating hinge, an oscillating rod, an oscillating platform, six hydraulic cylinders, an oil tank, a hydraulic motor, a power generator and an energy accumulator which are all arranged in the floater, wherein the sealing cover plate is fixedly connected to a protruding eave of the floater; the oil tank is fixedly connected to the floater; one end of the two-dimensional rotating hinge is fixedly connected to the sealing cover plate and the other end is connected to the oscillating rod; one end of the oscillating rod penetrates through the sealing cover plate to be fixedly connected to an external device and the other end is fixedly connected to the oscillating platform; the six hydraulic cylinders are connected in parallel to work; the two ends of the six hydraulic cylinders are respectively hinged to the oscillating platform and the oil tank through spherical hinges; the oil tank is connected with the hydraulic motor through a flow-dividing pipe and a return pipe; the power generator is connected with the hydraulic motor; the power generator and the hydraulic motor are arranged on the bottom surface of the floater; the energy accumulator is connected with the hydraulic motor. The novel parallel multidimensional oscillating sea wave power generation device has the advantages of long service life, low maintenance cost, low environmental pollution, capability of fully absorbing sea wave energy, high power generation efficiency and the like.

Owner:SHANGHAI JIAOTONG UNIV

Sun tracking method and sun tacking system device

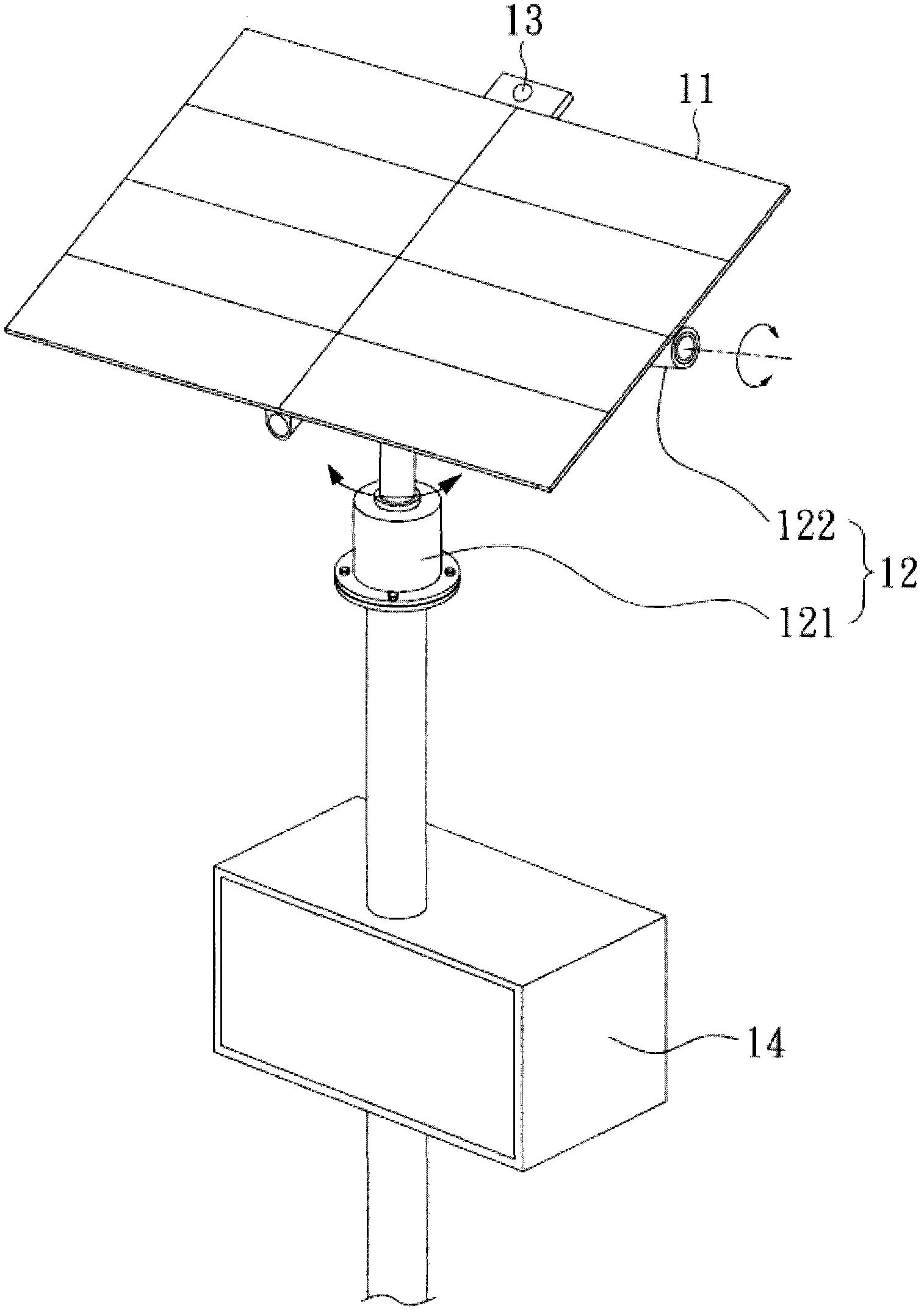

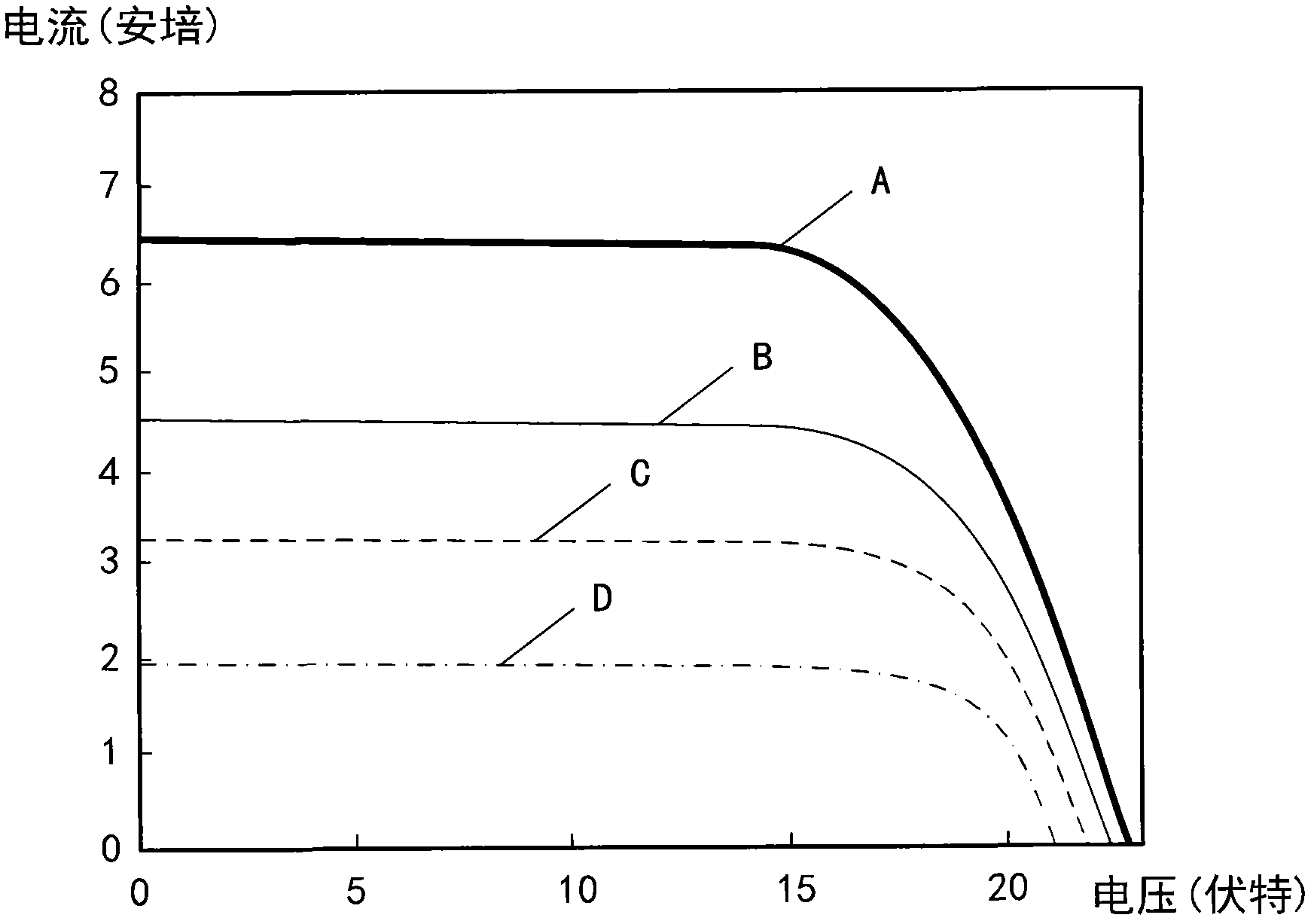

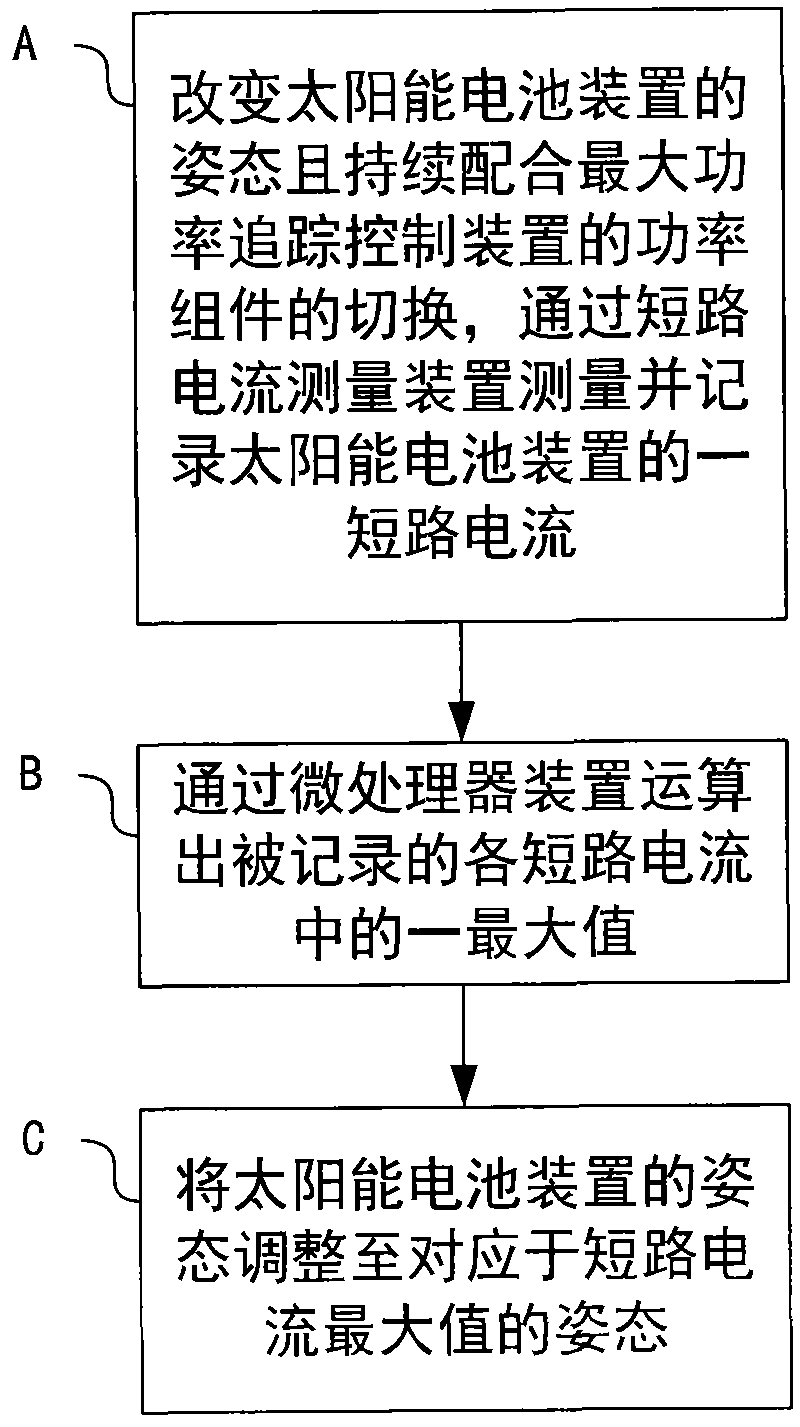

InactiveCN102621989ATracking lastsDoes not affect power generation efficiencyControl using feedbackMotor driveDrive motor

The invention relates to a sun tracking method which can continuously track the position of the sun without additionally mounting a photosensor, calculating the formula of sun track and timely correcting a mechanical structure, and a sun tracking system device. The sun tracking method comprises the following steps: (A) changing the attitude of a solar cell device, continuously matching with the switching of a power component of a maximum power tracking control device, measuring and recording short-circuit current through a short-circuit current measuring device, directly measuring and recording the short-circuit current through the short-circuit current measuring device or measuring and recording output power through a power measuring device of the maximum power track control device; (B) operating the maximum value of the recorded short-circuit current or the output power; and (C) driving a motor driving device and adjusting the attitude of the solar cell device to that corresponding to the maximum value of the short-circuit current or the output power.

Owner:NAT CENT UNIV

System preventing low-temperature corrosion of power station boiler

InactiveCN107062296AAvoid Low Temperature CorrosionImprove efficiencyLiquid degasificationCombustion processAir preheaterCold air

The invention discloses a system preventing low-temperature corrosion of a power station boiler and a method preventing the low-temperature corrosion of the power station boiler. Cold air is heated by hot water in an air water air preheater and then fed to a medium-temperature air preheater arranged in a rear smoke channel of the boiler, the temperature of the metal wall of the medium-temperature air preheater can be raised to be higher than the temperature of a smoke acid dew point, and therefore the low-temperature corrosion of the air preheater is avoided. A smoke water feeding heater is arranged behind the air preheater of the rear smoke channel of the boiler to reduce the exhaust smoke temperature, meanwhile, as the temperature of the gas entering the smoke water feeding heater is about 100 DEG C, the low-temperature corrosion of the smoke water feeding heater is also effectively avoided, the heat of the whole unit is not increased or decreased, and the power generation efficiency of the unit cannot be affected.

Owner:JIANGLIAN HEAVY IND GRP CO LTD

Ventilating, wind-preventing and freezing-preventing method for kiwi fruit orchard combined to photovoltaic power station

InactiveCN107371959ATotal cost impact ignoredReduce wearPV power plantsClimate change adaptationProtection forestActinidia

The invention discloses a ventilating, wind-preventing and freezing-preventing method for a kiwi fruit orchard combined to a photovoltaic power station. The kiwi fruit orchard combined to the photovoltaic power station comprises a kiwi fruit forest and photovoltaic array units, wherein the photovoltaic array units comprises photovoltaic wires; the photovoltaic wires comprises stand columns and cross beams connected with the stand columns; the stand columns support kiwi fruits during growth of the kiwi fruits; and the number of the photovoltaic wires is N, and N is greater than or equal to 1. The ventilating, wind-preventing and freezing-preventing method for the kiwi fruit orchard combined to the photovoltaic power station is characterized in that ventilating, wind prevention and freezing prevention of the kiwi fruit orchard combined to the photovoltaic power station are realized by the mode; and by the stand columns and the cross beams of the photovoltaic power station, wind shields and / or sunshade nets are arranged. On the basis of integration of an existing kiwi fruit forest, by mechanics characteristics and neat arrangement of the photovoltaic array stand columns and frames, requirements of ventilation, wind prevention and freezing prevention of the kiwi fruit orchard are met, the investment on the photovoltaic power station is not increased, the power generation efficiency of the photovoltaic power station is not affected, and establishment on a kiwi fruit protection forest or a windproof barrier is not increased.

Owner:ZHENGZHOU FRUIT RES INST CHINESE ACADEMY OF AGRI SCI

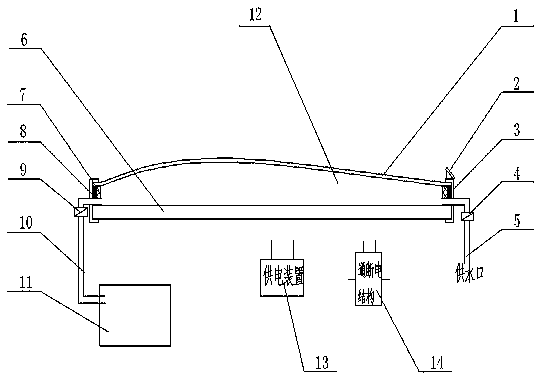

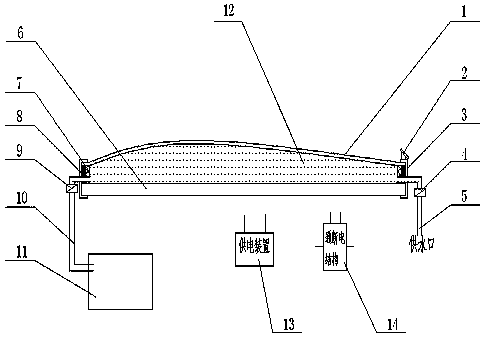

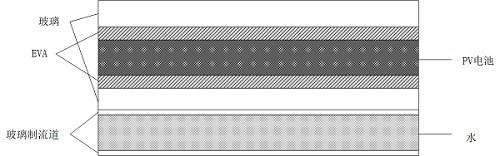

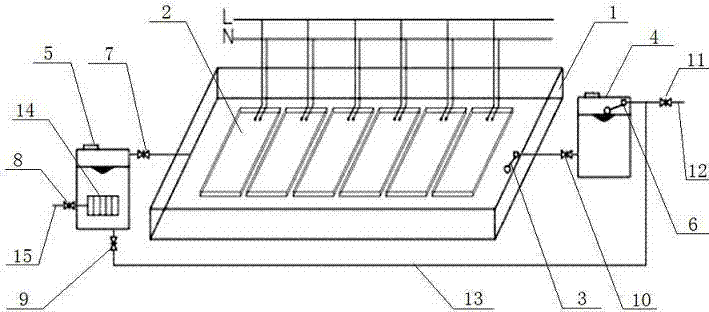

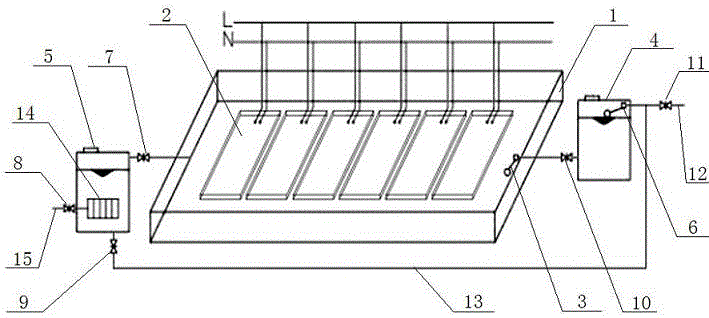

Automatic water-cooled photovoltaic system

InactiveCN109798673ADoes not affect power generation efficiencyImprove heat utilizationSolar heating energySolar heat collector controllersSolenoid valveWater storage tank

The invention discloses an automatic water-cooled photovoltaic system. The automatic water-cooled photovoltaic system comprises a first photovoltaic panel, a waste heat recovery system and an automatic power on-off system. The first photovoltaic panel comprises a light-transmitting structure, a lower photovoltaic panel body and an aluminum frame, wherein a hollow layer is arranged between the lower photovoltaic panel body and the light-transmitting structure. The waste heat recovery system comprises a first water pipe, a normally closed solenoid valve, a second water pipe, a normally open solenoid valve and a water storage tank. The automatic power on-off system comprises a second photovoltaic panel arranged on the aluminum frame, a power supply device arranged on one side of the first photovoltaic panel and a power on-off structure, wherein the power on-off structure is used for communicating when the generating power of the second photovoltaic panel is greater than a preset generating power, and is further used for being disconnected when the generating power of the second photovoltaic panel is less than or equal to the preset generating power. The automatic water-cooled photovoltaic system is simple in structure, and the waste heat recovery effect and power generation efficiency of photovoltaic modules can be improved at the same time.

Owner:吴祥初

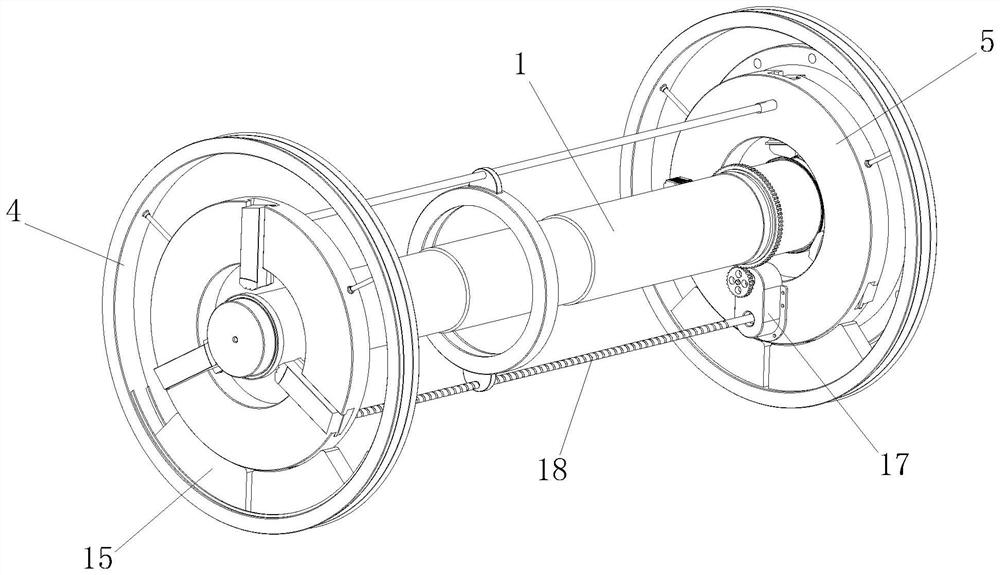

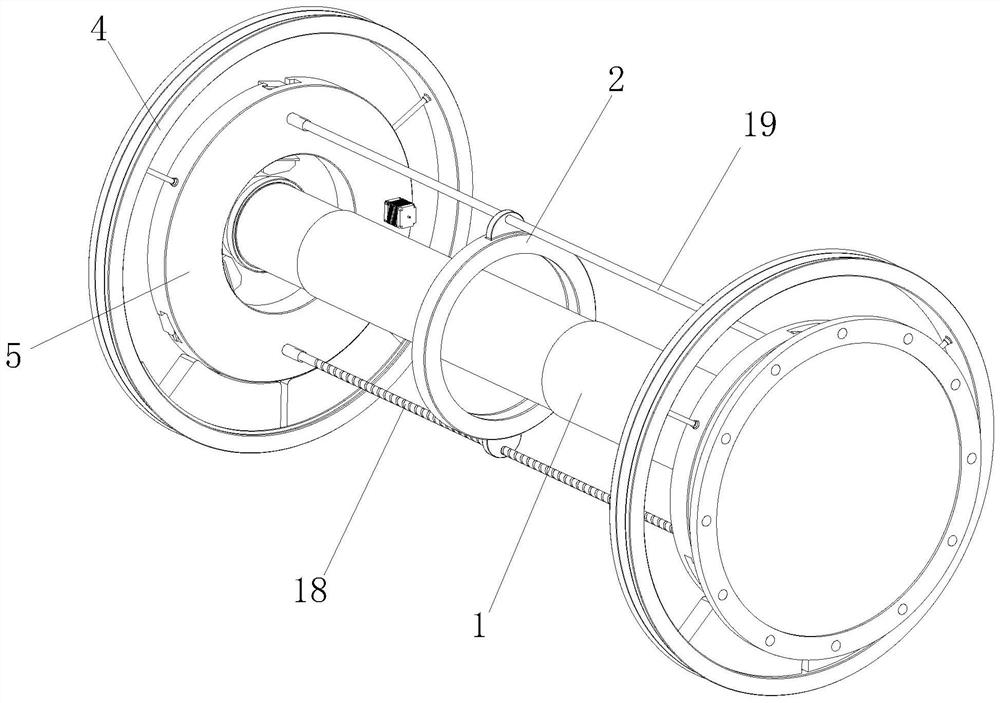

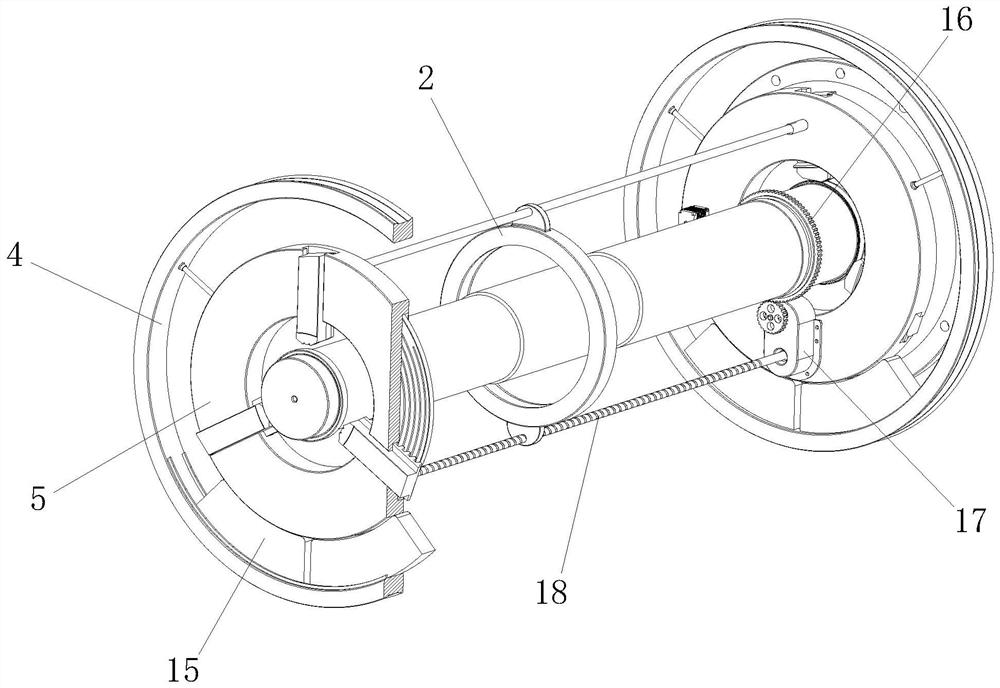

Main shaft fatigue detection equipment for wind generating set

PendingCN114354745ADoes not affect power generation efficiencyImprove practicalityAnalysing solids using sonic/ultrasonic/infrasonic wavesMachines/enginesWind drivenReduction drive

The invention relates to a wind driven generator, and discloses a main shaft fatigue detection device for a wind generating set, which comprises a main shaft, a detection ring for ultrasonic flaw detection on the surface of the main shaft is sleeved on the main shaft, and two ends of the main shaft are also provided with installation assemblies for installing the detection ring and keeping relatively static when the main shaft rotates. A driving assembly for driving the detection ring to reciprocate is arranged on the mounting assembly, a speed reducer for adjusting the rotating speed is further arranged between the driving gear ring and the driving screw rod, and a connecting mechanism for controlling the input end of the speed reducer to be connected with the driving gear ring is arranged in the speed reducer. The surface of the main shaft can be intermittently scanned and detected by the detection ring in the horizontal direction, rotation of the main shaft does not need to be stopped, intelligent main shaft flaw detection is achieved, meanwhile, the power generation efficiency of the main shaft is not affected, the overall practicability of the detection equipment is further improved, shaft diameter changes of different sections of the main shaft can be adapted, and the detection efficiency is improved. And adaptive rapid clamping installation is achieved.

Owner:中国大唐集团科学技术研究总院有限公司

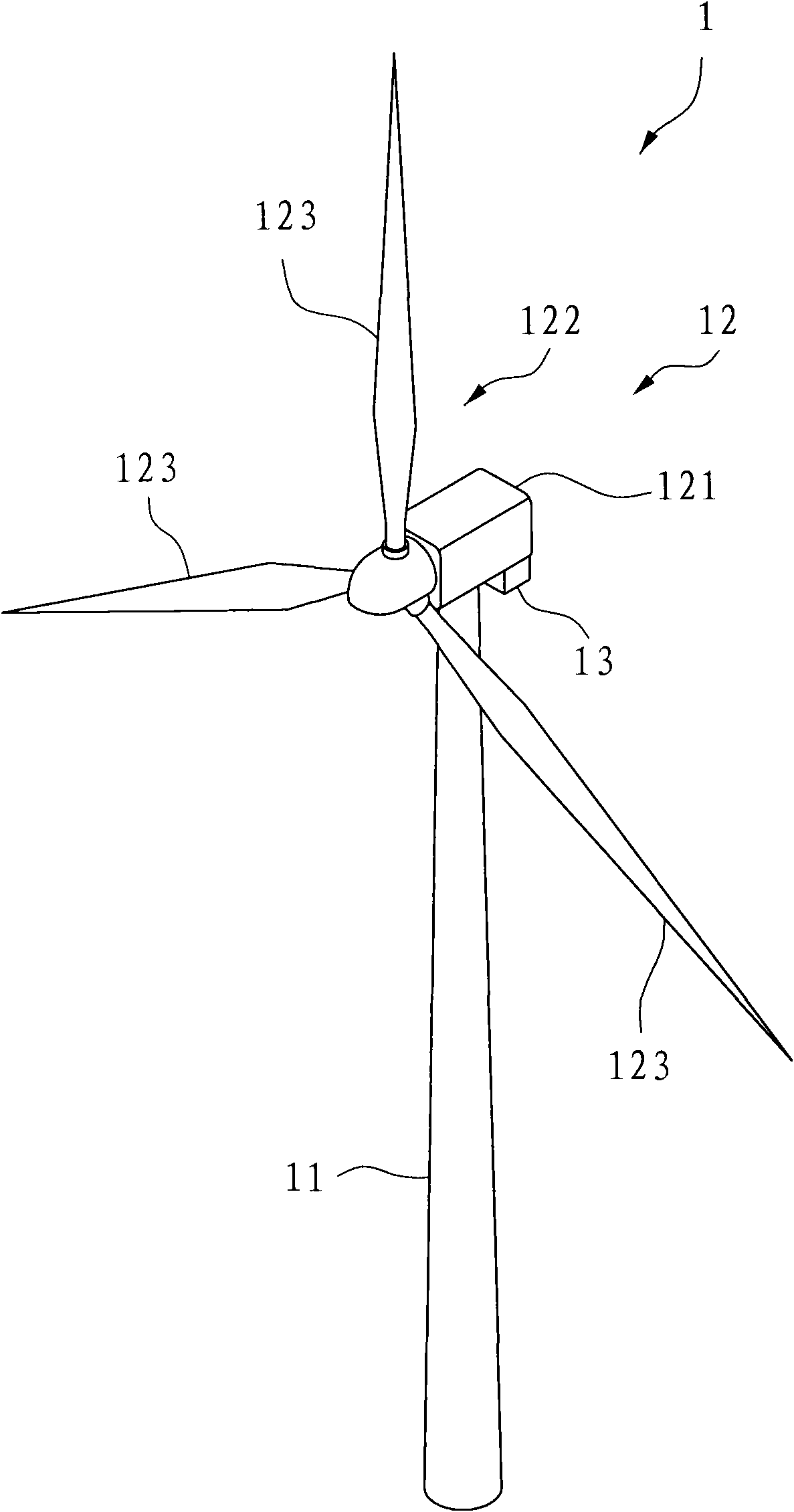

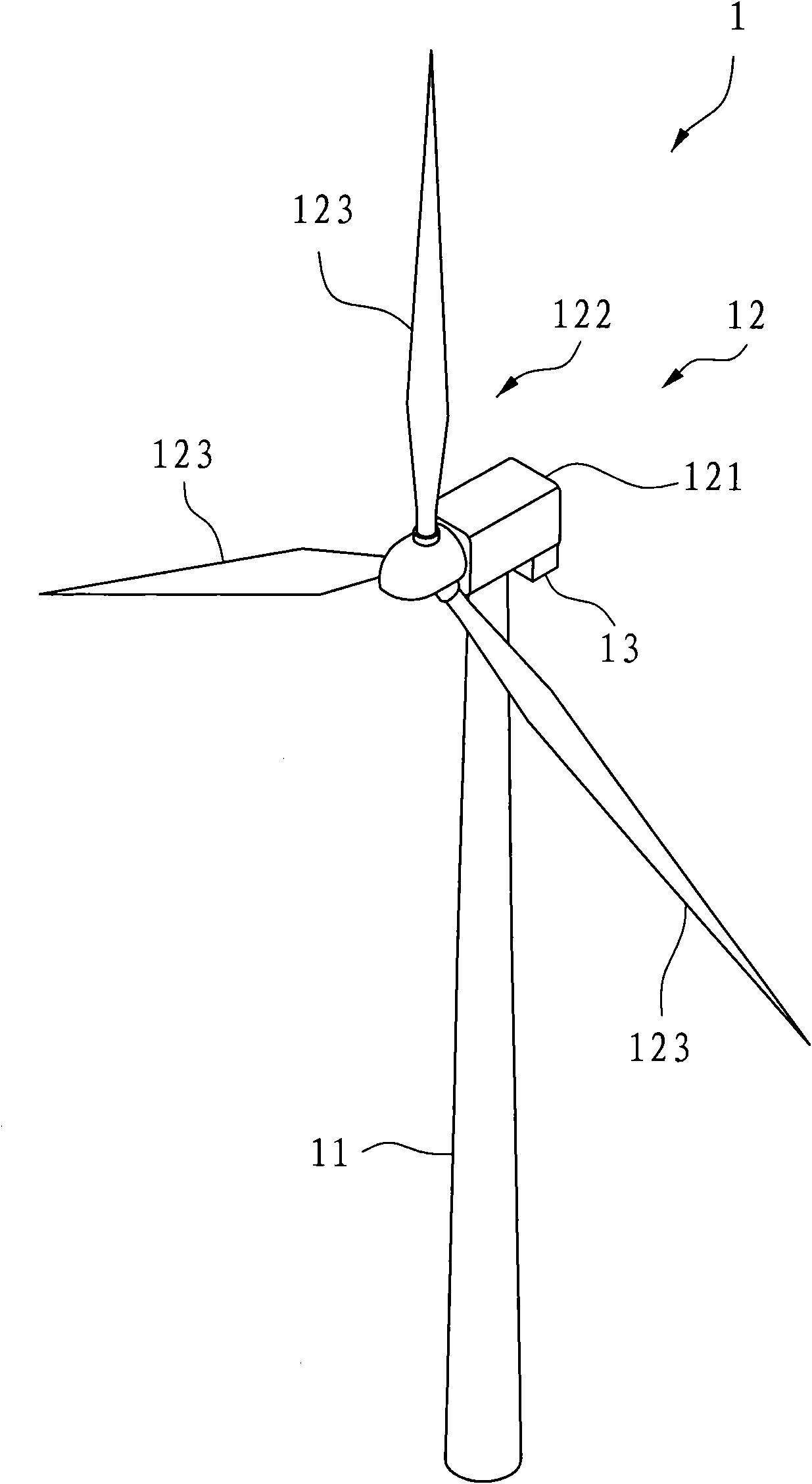

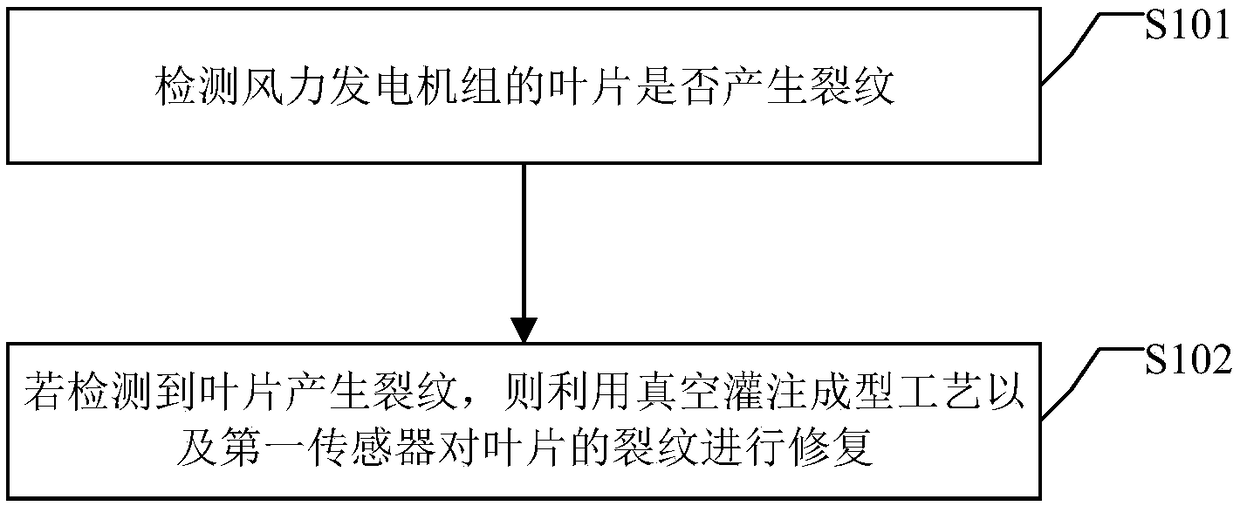

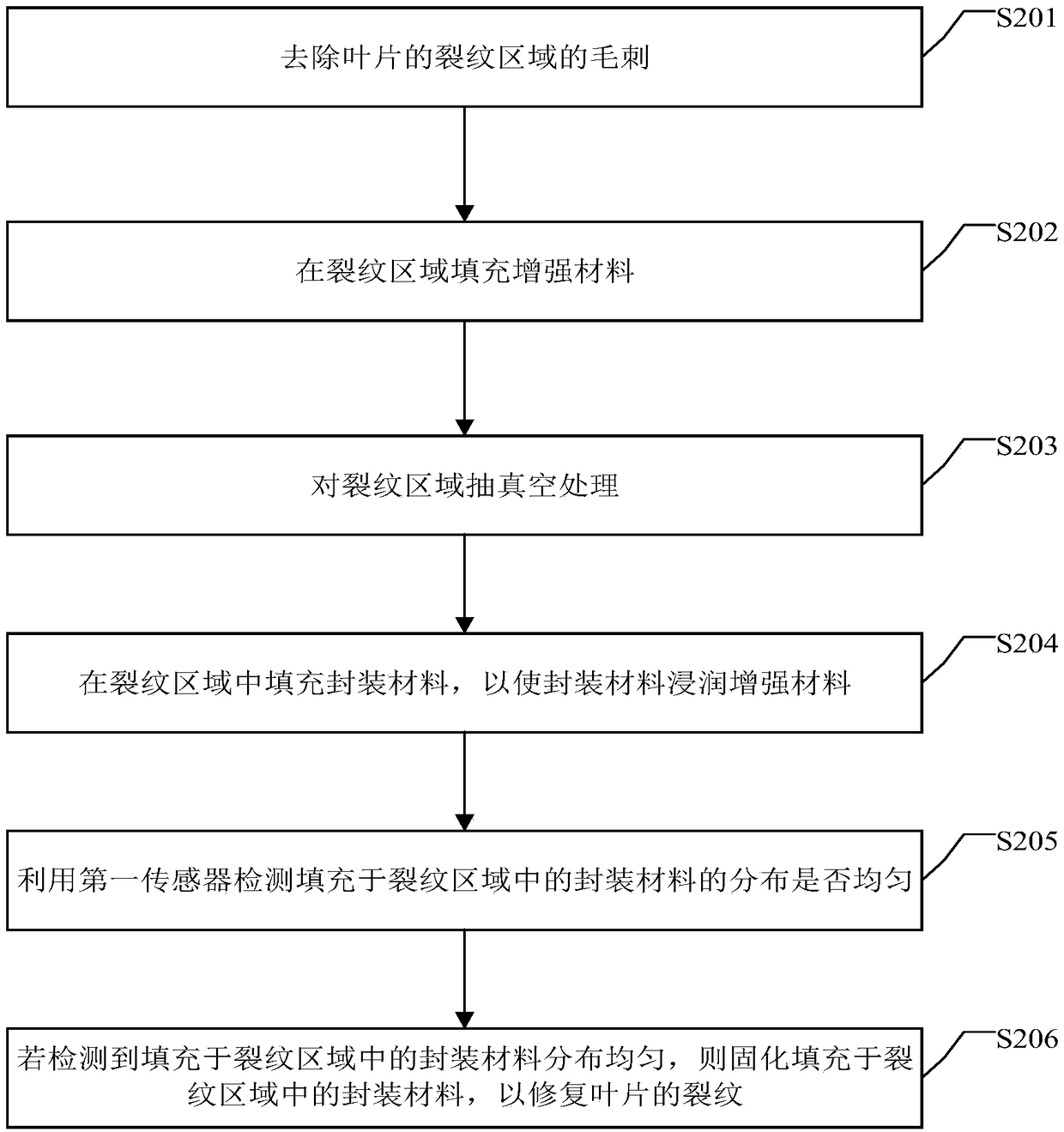

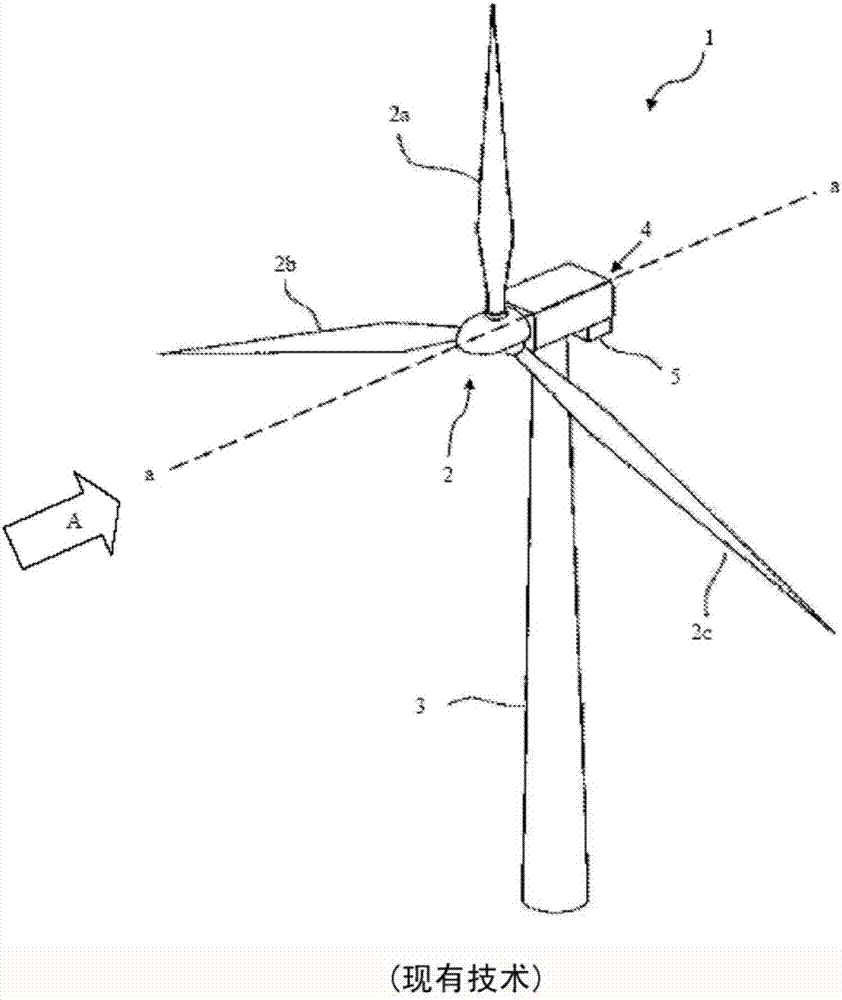

Method for repairing cracks of blades of wind turbine generator system

The invention discloses a method for repairing the cracks of the blades of a wind turbine generator system. The method comprises following steps: detecting whether the blades of a wind turbine generator system have cracks or not; and repairing the cracks by a vacuum assisted resin infusion technology and a first sensor if the blades have cracks. The provided method has the advantages that the repairing effect is improved, after repairing, the blades do not have any crack, and the generation efficiency is not influenced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

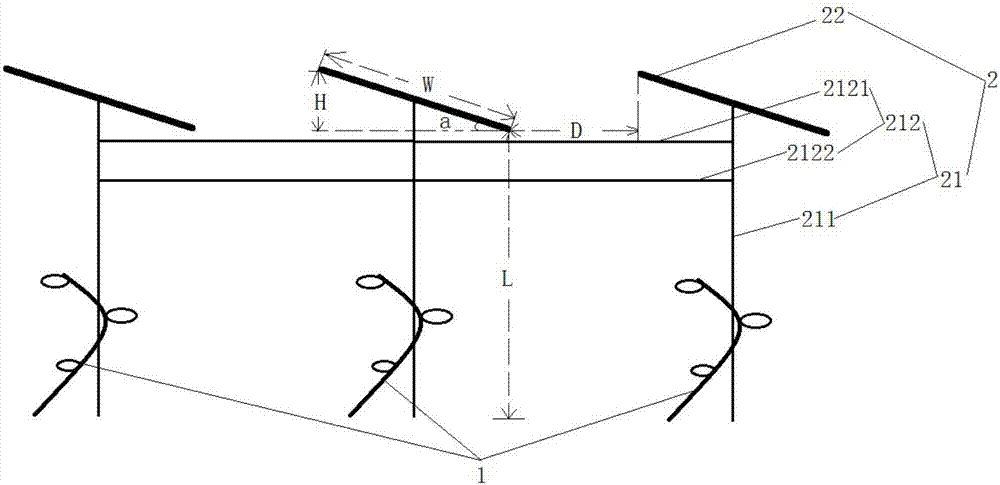

Weak and diffused light illumination implementation method of kiwi fruit orchard combined with photovoltaic power station

ActiveCN107318496AEasy to adjustHigh selectivityRenewable energy machinesHorticulture methodsWire rodGreenhouse

The invention discloses a weak and diffused light illumination implementation method of a kiwi fruit orchard combined with a photovoltaic power station. The kiwi fruit orchard combined with the photovoltaic power station comprises kiwi fruit trees and N photovoltaic array units and is characterized in that each photovoltaic array unit comprises a photovoltaic wire, the photovoltaic wire comprises a standing column and a crossbeam connected with the sanding column; the standing columns provide support for the growth of kiwi fruit; N> / =1; weak and diffused light illumination is achieved by using special greenhouse glass. The method has the advantages that the special greenhouse glass is mounted on the frames of the existing photovoltaic components in the photovoltaic power station, the photovoltaic components and the special greenhouse glass are designed according to actual needs and combined at appropriate positions according to the proportion, an openable and adjustable shading device is arranged at the special greenhouse glass in an assisted manner to change direct light into diffused light and change strong light into weak light, high transmittance, high uniformity, high regulating performance and high selectivity of the illumination are achieved, and the growth of the kiwi fruit is benefited.

Owner:北京晶农科技有限公司

Double-sided power generation glass assembly and preparation method thereof

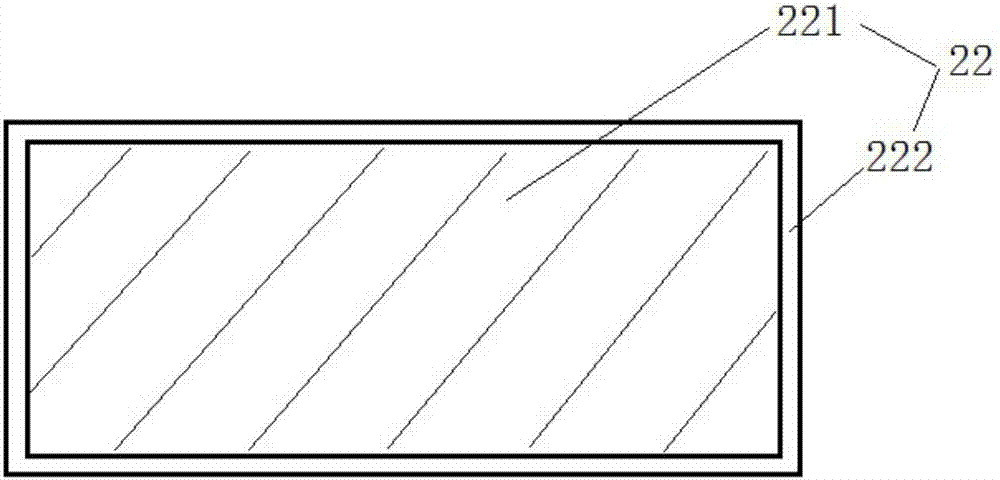

PendingCN112909115AWith the function of double-sided power generationPrevent sideslipPhotovoltaic supportsPhotovoltaic energy generationLayered structureLamellar structure

The invention discloses a double-sided power generation glass assembly and a preparation method thereof. The double-sided power generation glass assembly comprises a power generation glass component I, a spacing bar, a power generation glass component II and a junction box, the power generation glass component I and the power generation glass component II are of a layered structure, and the upper side and the lower side of the spacing bar are connected with the power generation glass component I and the power generation glass component II correspondingly; a hollow layer is formed between the power generation glass component I and the spacing bar and between the power generation glass component II and the spacing bar, a light-emitting element is fixed in the hollow layer, other parts, except the light-emitting element, in the hollow layer are filled with sound insulation materials, and the junction boxes are arranged on the outer sides of the power generation glass component I and the power generation glass component II respectively. The junction box is connected with the power generation glass component I and the power generation glass component II through electrode leads. The assembly improves the generating capacity, and has a soundproof effect and excellent strength and hardness.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

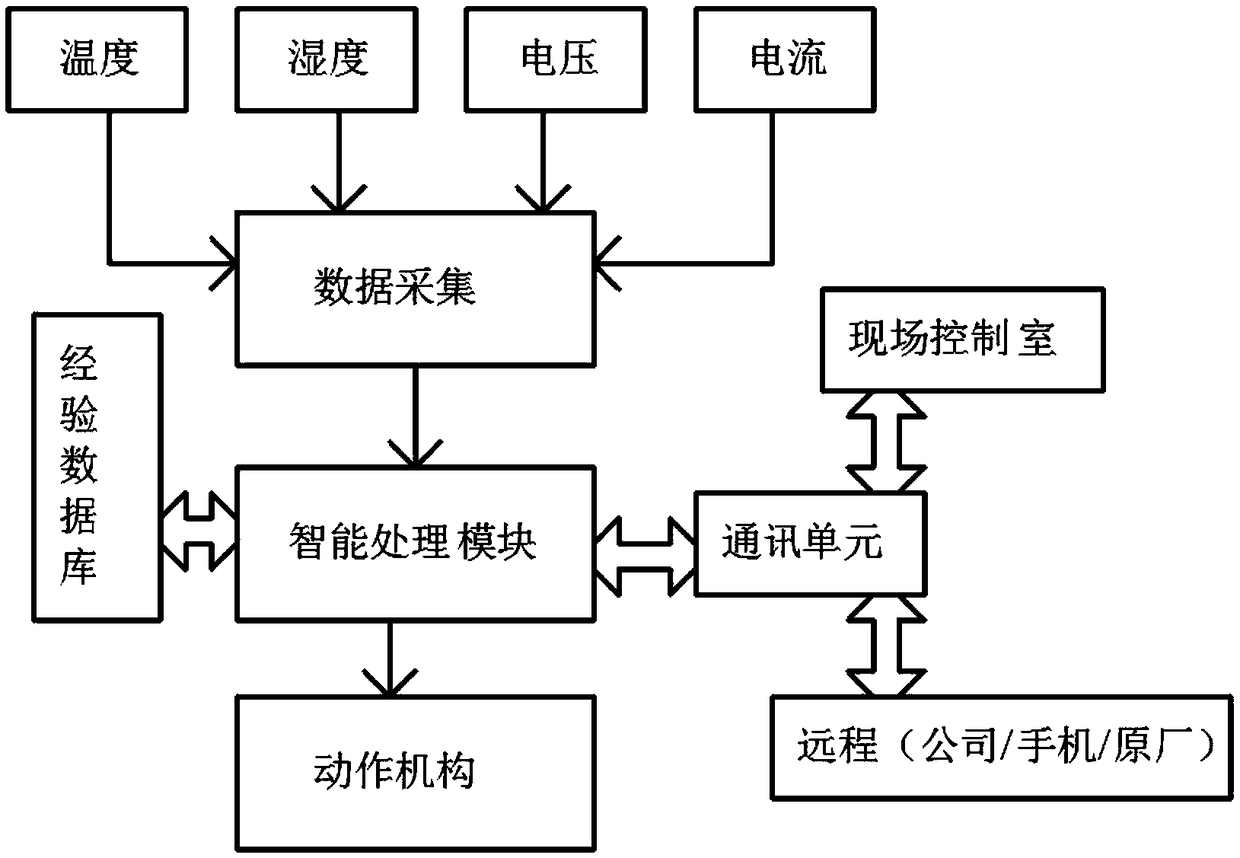

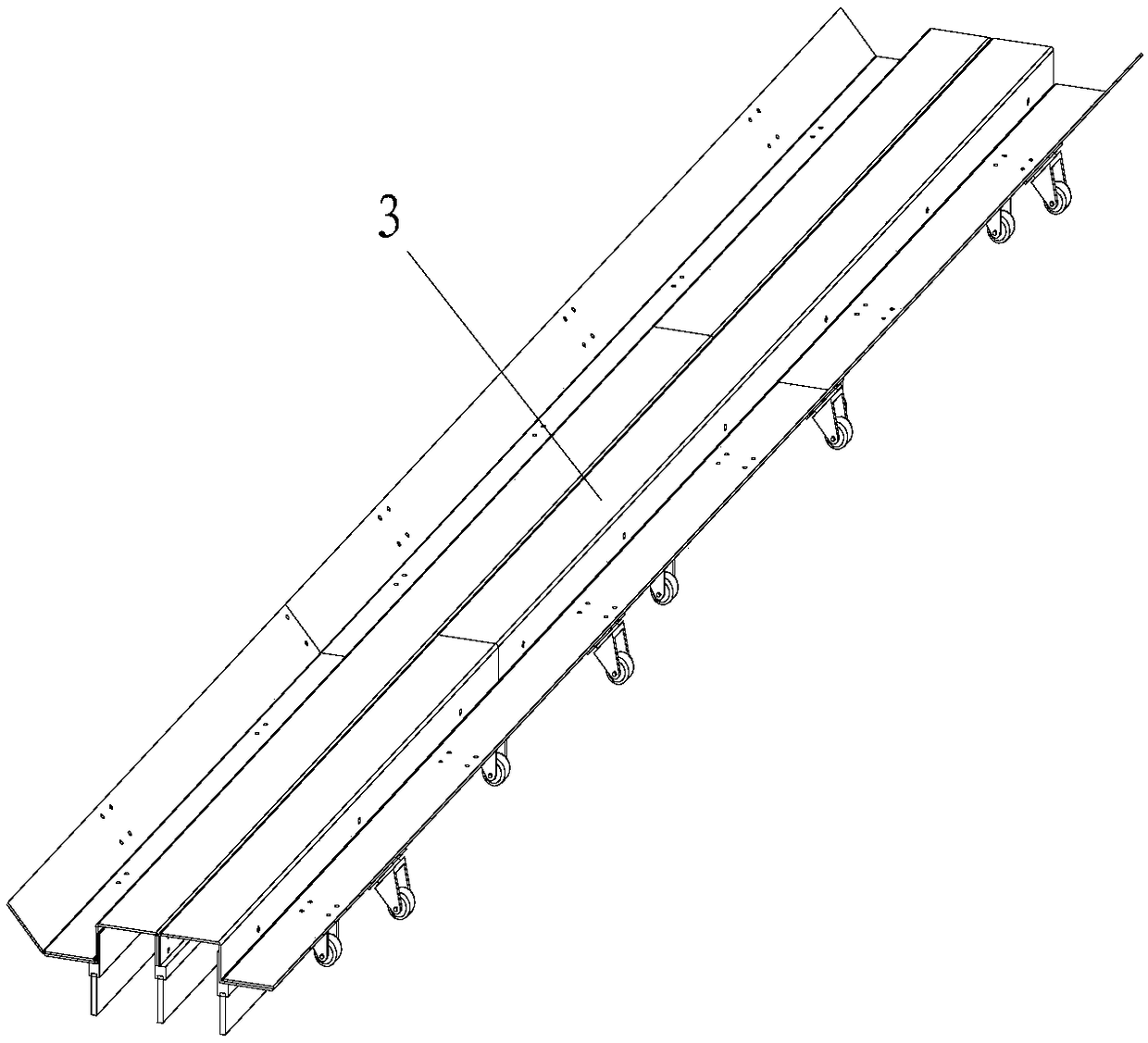

Photovoltaic power plant multifunctional intelligent management method and system

ActiveCN106385220BCleanliness SmartGuaranteed cleanlinessCircuit arrangementsPV power plantsElectricityArray data structure

The invention relates to the field of photovoltaic power station management and especially relates to a photovoltaic power station multifunctional intelligent management method and system. The factors of a component current output power, an environment condition and a weather condition are integrated, a preliminary judgment is carried out according to an experience array, a result is outputted, and a cleaning task is performed. Combined with measurement data after cleaning, the process data of the judgment result of a last time is subjected to precision comparison, the correction factor of a judgment function is corrected, the above steps are repeated, and the system operation precision and reliability are increased day by day. At the same time, the combination of multiple brushes is used, the various types of dust and floating ash can be removed, and the dust adsorption is prevented. A flexible driving is employed, and the implementation difficulties of uneven component installation, adjacent arrays which are not aligned, and wavy slope arrays can be overcome. By using a PV power taking mode, AC and DC input are compatible, PV series direct branch power taking is achieved, the whole series power taking nearly does not affect power generation efficiency, and the energy consumption is reduced.

Owner:常州元乾智能科技有限公司

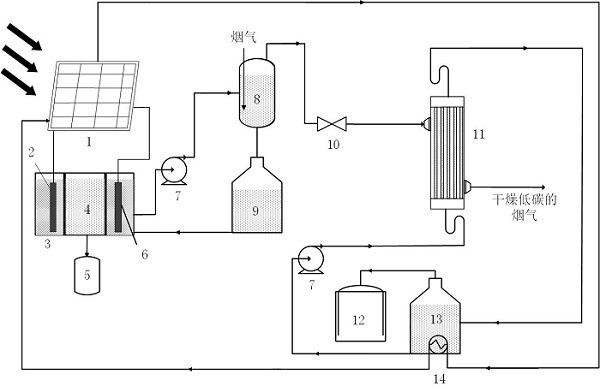

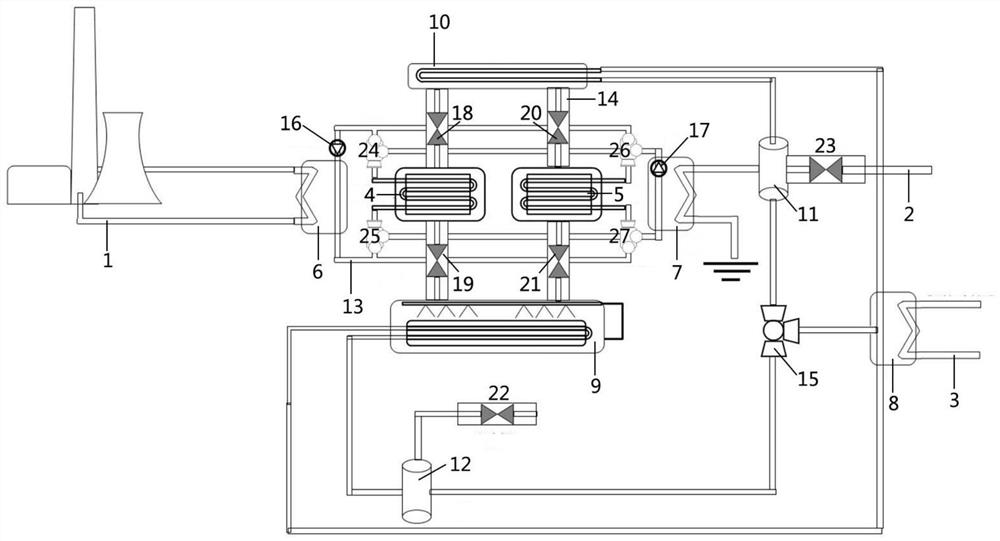

Flue gas moisture recovery and decarburization system based on concentrating photovoltaic photo-thermal

PendingCN113209784ADoes not affect power generation efficiencyReduce mass transfer resistanceGas treatmentDispersed particle separationChemistryCondensing lens

A flue gas moisture recovery and decarbonization system based on concentrating photovoltaic photo-thermal comprises a concentrating photovoltaic photo-thermal subsystem, a flue gas moisture recovery subsystem and a flue gas decarbonization subsystem. According to the system, solar energy is absorbed by adopting the CPV / T (concentrating photovoltaic photo-thermal system), and electric energy and heat energy are more efficiently produced through the reflection effect of a CPC collecting lens; moisture in the flue gas is recovered by adopting a solution absorption method, and a circulating solution (LiCl solution) is regenerated by adopting an electrodialysis method; and membrane method decarburization is adopted, a ceramic membrane combination is selected to form a membrane assembly, and absorption liquid (ethanolamine solution) is regenerated by utilizing waste heat of a solar cell panel, so that gradient utilization and comprehensive utilization of energy are realized. The system provides an efficient, energy-saving and environment-friendly innovative solution for water recovery and decarburization of the flue gas of the power plant, and has great application potential and comprehensive economic benefits in the aspect of flue gas treatment of the coal-fired power plant.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

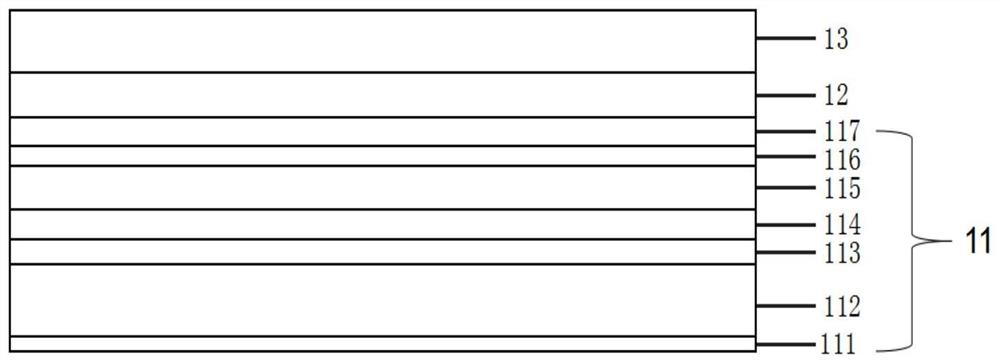

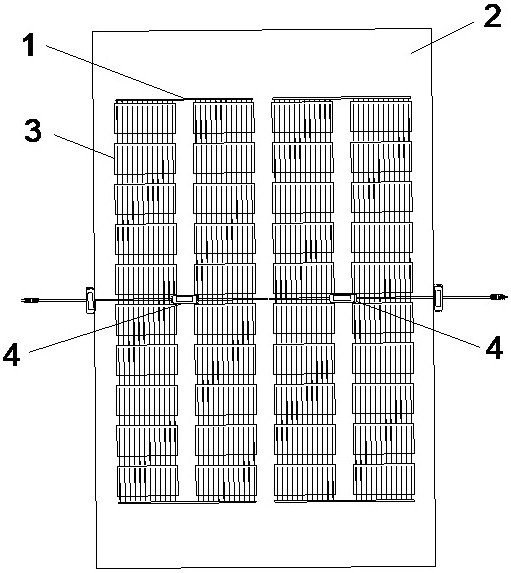

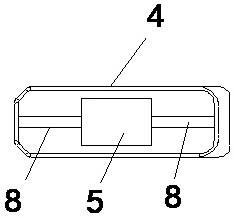

BIPV intelligent chip photovoltaic module and packaging process thereof

PendingCN114335219AIncrease power outputImprove reliabilityPhotovoltaic energy generationSemiconductor devicesElectric energyEngineering

The invention relates to a BIPV intelligent chip photovoltaic module and a packaging process thereof, the BIPV intelligent chip photovoltaic module comprises a BIPV module, front plate toughened glass, intelligent chip boxes and back plate toughened glass, the BIPV module comprises a plurality of battery strings, each battery string is formed by connecting a plurality of solar battery pieces in series, one intelligent chip box is arranged between two adjacent battery strings at the left part, and the back plate toughened glass is arranged on the back plate toughened glass. Another intelligent chip box is also arranged between two adjacent battery strings at the right part; an intelligent chip is arranged in the intelligent chip box, a bus bar is arranged at the left end of the intelligent chip and extends out of the intelligent chip box to be connected with an adjacent solar cell, and a bus bar is arranged at the right end of the intelligent chip and extends out of the intelligent chip box to be connected with an adjacent solar cell. According to the invention, the intelligent chip is packaged in the photovoltaic module, and the chip is connected in series with the two columns of battery pieces, so that the power optimization of the sub-cascade crystalline silicon battery pieces is realized, the output of electric energy is increased, the reliability of the module is enhanced, the BIPV of the crystalline silicon intelligent photovoltaic module is realized, and the photovoltaic module can be installed on each building elevation.

Owner:SUZHOU AIKANG LOW CARBON TECH INST +1

Small photo-thermal combination solar power station

InactiveCN103795327AReduce heat lossSimple structurePV power plantsPhotovoltaic energy generationWater circulationEngineering

The invention discloses a small photo-thermal combination solar power station. The small photo-thermal combination solar power station comprises a shallow water channel and solar power generation components, wherein the solar power generation components are arranged in the shallow water channel in an array mode, water is poured into the shallow water channel, it is guaranteed that the upper surfaces of the solar power generation components are not soaked in water, all the solar power generation components are connected with an inverter and a load in sequence after being connected in parallel or in series to form a distributed solar power station, the inverter and the load are arranged outside the shallow water channel, a water outlet is formed in the bottom of one side edge of the shallow water channel, a first ball float valve is arranged on the other side edge of the shallow water channel and connected with a cold water tank and controls the water level of the shallow water channel, a second ball float valve is arranged in the cold water tank, the cold water tank is connected with a cold water circulating mechanism and a water inlet pipe through the second float ball valve, and the other end of the cold water circulating mechanism is connected with the water outlet through a first stop valve. The small photo-thermal combination solar power station is simple in structural design, low in cost, good in cooling performance, high in power generation efficiency, and capable of sufficiently collecting and utilizing heat emitted by the solar power generation components.

Owner:江苏万丰光伏有限公司

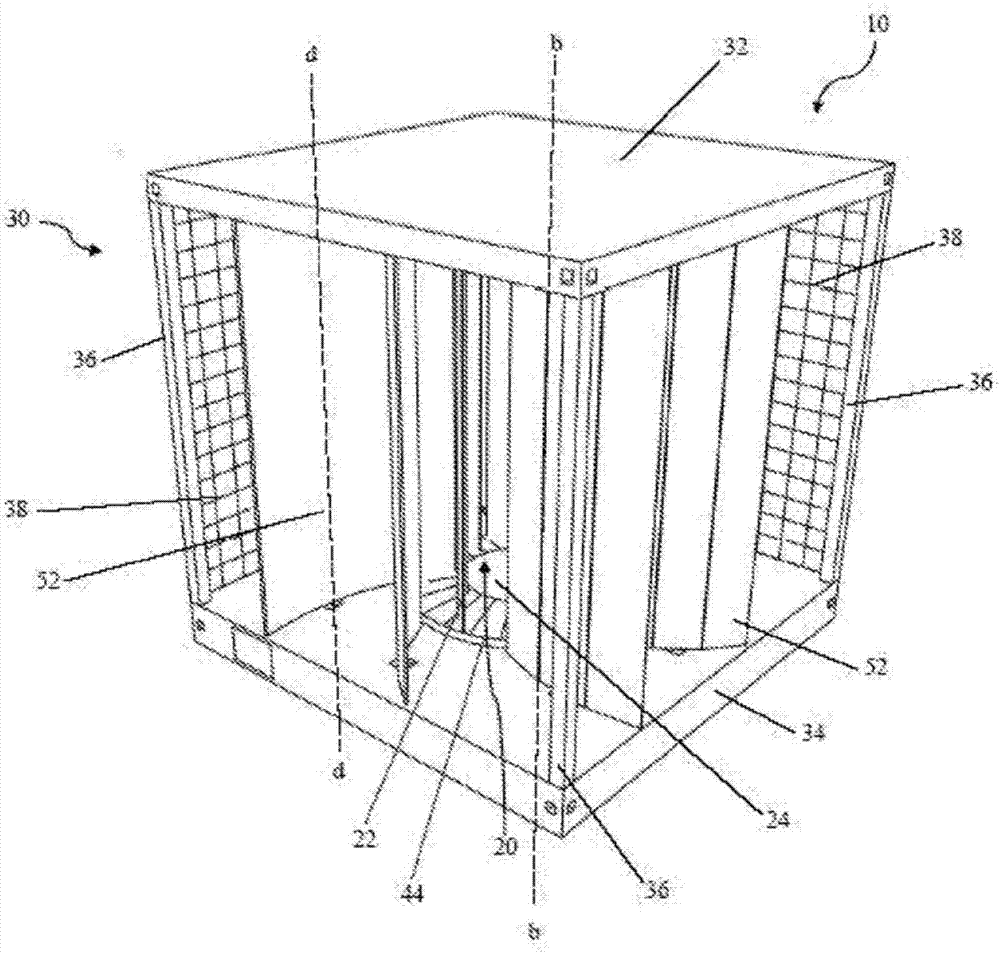

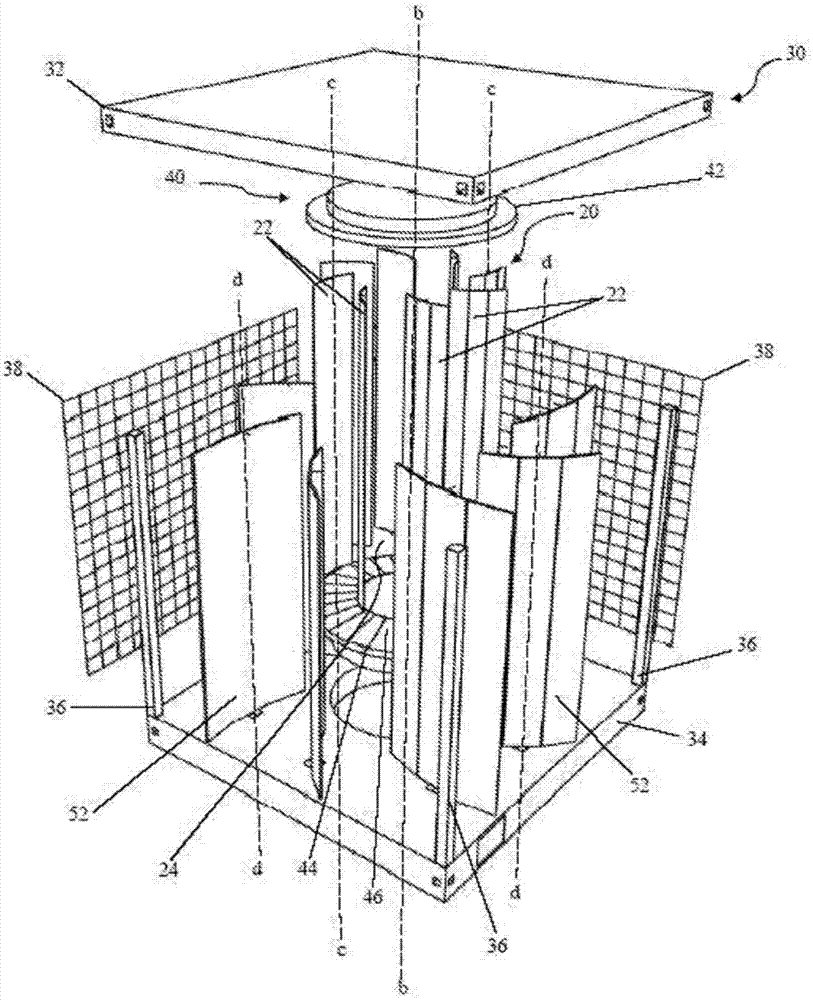

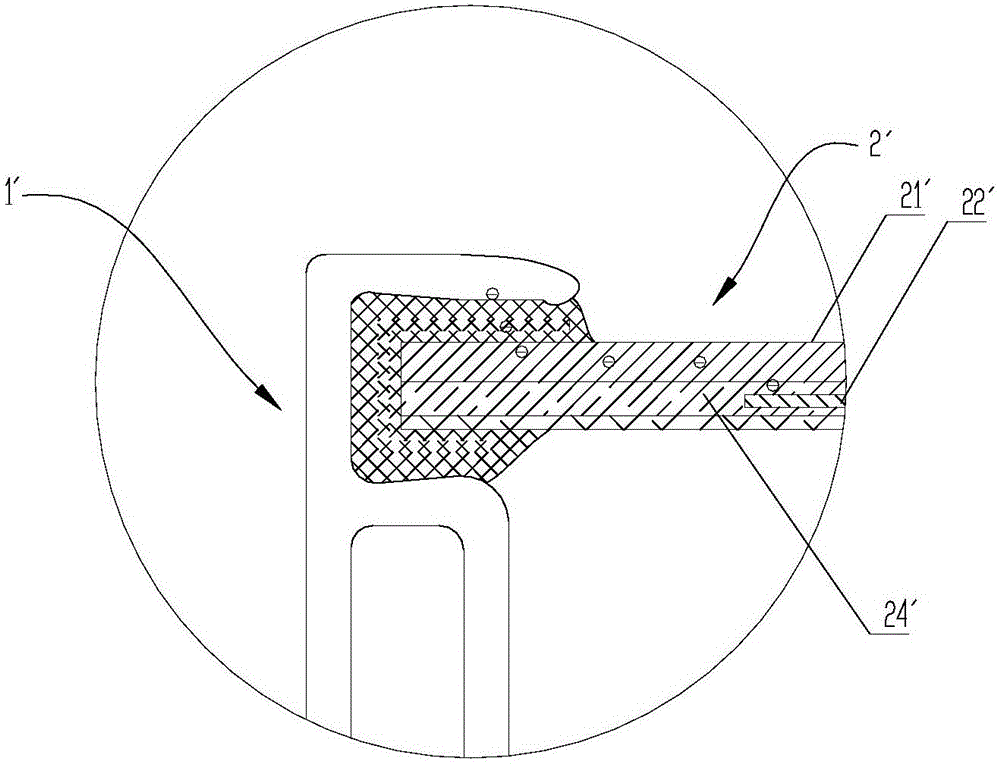

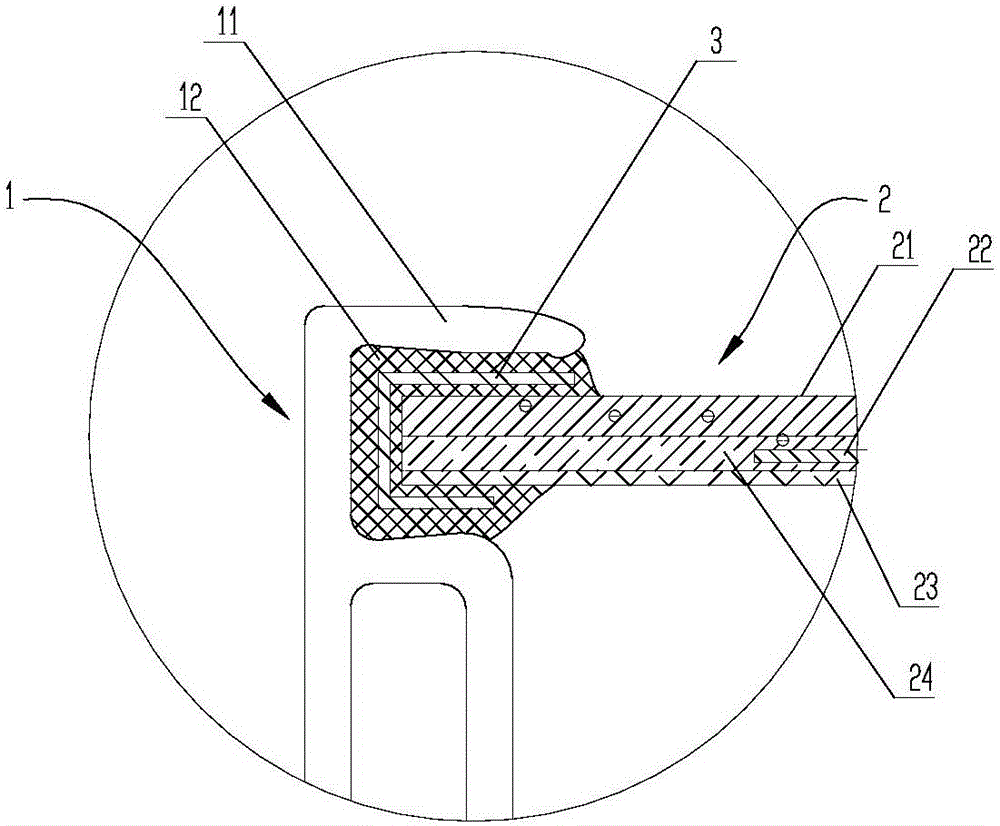

Device and system for wind power generation

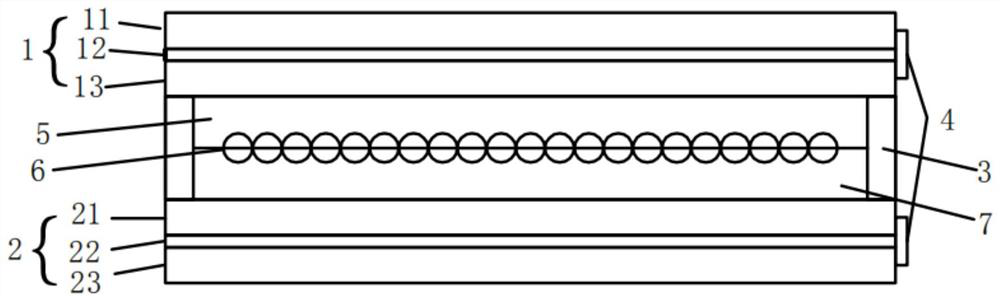

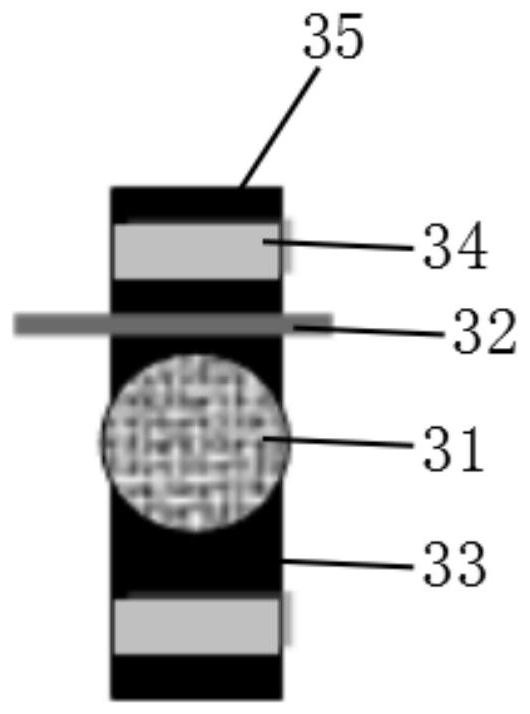

InactiveCN107250531ADoes not affect power generation efficiencyMeet the requirements of different locationsWind motor controlRenewable energy generationEngineeringWind power system

A device (10) for wind power generation, comprising: a blade assembly (20) having a plurality of radially extending blades (22) surrounding a hollow space (24); a frame structure (30) inside which the blade assembly (20) is rotatably mounted; and a power generating unit (40) connected with the blade assembly (20); wherein the blade assembly (20) is rotatable by at least one air flow directed into the blade assembly (20), so that rotation of the blade assembly (20) is adapted to drive the power generating unit (40) to thereby generate electrical energy. And a system (100) comprises a plurality of the devices (10) arranged in at least one of a horizontal and a vertical arrangement relative to one another.

Owner:蒋素芳 +2

Anti-potential induced degradation (PID) effect photovoltaic component

ActiveCN106299001AImplement encapsulationDoes not compromise electrical safetyPhotovoltaicsPhotovoltaic energy generationPotential induced degradationEngineering

The present invention relates to the technical field of solar photovoltaic components, and particularly relates to an anti-potential induced degradation (PID) effect photovoltaic component. The anti-PID effect photovoltaic component comprises a frame and a photovoltaic laminated component disposed in the frame. An insulating structure is disposed between the frame and the photovoltaic laminated component. Due to the insulating structure, electron mobility between the frame and the photovoltaic laminated component is prevented, so that the PID effect is resisted. The PID resisting manner neither lowers the power generation efficiency of the photovoltaic component nor affects electrical safety of the photovoltaic system. The anti-PID effect photovoltaic component is encapsulated based on slightly changing the original regular component encapsulation process, so that the cost is not increased sharply, and the operation is relatively simple.

Owner:GREE ELECTRIC APPLIANCES INC

A small combined photothermal solar power station

InactiveCN103795327BPrevent absorption and releaseReduce lossesPV power plantsPhotovoltaic energy generationThermodynamicsEngineering

The invention discloses a small photothermal combined solar power station, which includes a shallow water tank and solar power generation components. The solar power generation components are arranged in an array in the shallow water tank, and water is injected into the shallow water tank to ensure that the upper surface of the solar power generation component is not soaked in In the water, each solar power generation module is connected in parallel or in series and then connected to the inverter and load placed outside the shallow water tank to form a distributed solar power plant; one side of the shallow water tank has a water outlet at the bottom, and the other side of the shallow water tank has a water outlet. There is a first float valve, the first float valve is connected to the cold water tank and controls the water level of the shallow water tank, the cold water tank is provided with a second float valve, the cold water tank is connected to the cold water circulation mechanism and the water inlet pipe through the second float valve, the cold water circulation mechanism The other end is connected to the water outlet through the first shut-off valve. The invention has the advantages of simple design structure, low cost, good heat dissipation and high power generation efficiency, and can fully collect and utilize the heat emitted by solar power generation components.

Owner:江苏万丰光伏有限公司

A method for reducing lightning disasters applicable to wind turbines

ActiveCN105736257BDoes not affect shapeDoes not affect power generation efficiencyMachines/enginesWind energy generationEngineeringHigh pressure

Owner:吉林市简通电气科技有限公司

Combined cooling, heating and power system and method based on adsorption type heat pump and utilizing coal-fired flue gas

ActiveCN113324348ADoes not affect power generation efficiencyStable supplyMechanical apparatusHeat pumpsWater pipeWater storage tank

The invention relates to a combined cooling heating and power system and method based on an adsorption type heat pump and utilizing coal-fired flue gas. The system comprises a coal-fired unit flue gas pipeline, an adsorption type heat pump unit, a heat supply water pipe and a circulating gas channel; the coal-fired unit flue gas pipeline is connected with a first heat exchanger; a water outlet of a second heat exchanger is connected with a hot water tank; the first heat exchanger, the second heat exchanger, a first adsorption bed and a second adsorption bed are connected through a circulating heat source pipe; working mediums in the first adsorption bed, the second adsorption bed, a condenser and an evaporator form circulation through a medium flowing pipe; the hot water tank is further connected with a water outlet of the condenser, a hot water supply pipe and a third heat exchanger; the circulating gas channel is connected with the third heat exchanger; a water inlet of the evaporator is connected with the third heat exchanger; and a water outlet of the evaporator is connected with a cold water tank. High-temperature flue gas generated by fire coal can be utilized in a gradient mode to supply domestic hot water, heat supply and refrigeration, and a water storage tank is arranged, so that the stable heat and cold supply function in the peak period is achieved.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD +1

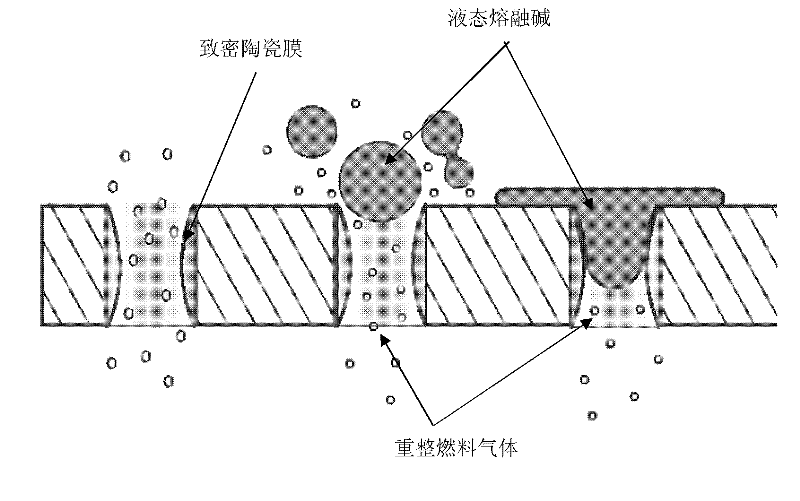

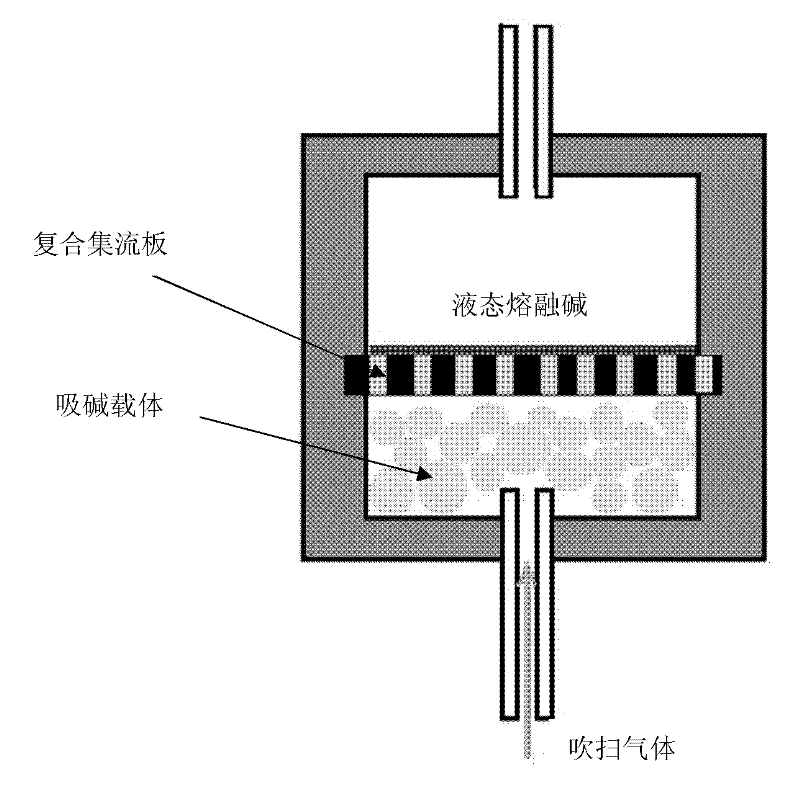

Preparation method of composite soda blocking collector plate

InactiveCN101867051BReduce churnIncreased operating lifeCell electrodesFuel cell detailsNew energyLiquid state

Owner:DALIAN UNIV OF TECH

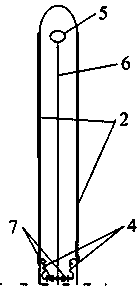

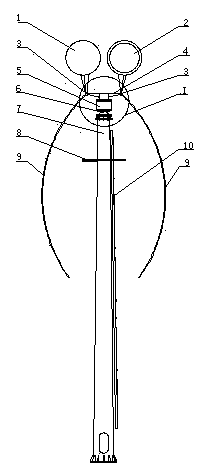

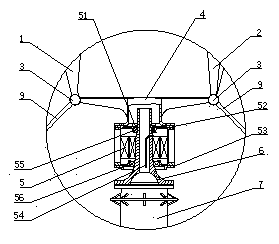

Novel vertical shaft wind power generator

InactiveCN103967708AImprove boot performanceSimple structureRenewable energy generationWind motor combinationsWind forceAerospace engineering

The invention discloses a novel vertical shaft wind power generator which comprises a left starting auxiliary wing cup (1), a right starting auxiliary wing cup (2), a blade rotating support (4), a power generator (5), a vertical shaft flange (6), a tower rod (7) and two symmetrically-mounted lift blades (9). The power generator (5) comprises a clamping ring (51), an upper end cap (52), a lower end cap (53), a power generator lead (54), an upper bearing (55) and a lower bearing (56), the lift blades (9) are connected with the blade rotating support (4) through hinges (3), a maintenance platform (8) and a climbing ladder (10) are arranged on the tower rod (7), and the left starting auxiliary wing cup (1) and the right starting auxiliary wing cup (2) are hemispherical cups identical in size. Starting performance can be improved remarkably, and the novel vertical shaft wind power generator is simple in structure and high in power generation efficiency.

Owner:黄石华科新能源科技有限公司

Process method and device for removing hydrogen chloride by powder spraying in blast furnace gas pipeline

ActiveCN111378801BImprove uniformityImprove sufficiencyBlast furnace detailsIncreasing energy efficiencyThermodynamicsSmall footprint

The invention discloses a process method and device for removing hydrogen chloride by powder spraying of blast furnace gas pipelines. The device for removing hydrogen chloride by powder spraying of blast furnace gas pipelines is used to remove hydrogen chloride by dry spraying blast furnace gas dechlorination process; Install the dechlorination agent bag filter hopper, pulverizer and fan on the pipeline after the dry coarse dust collector and before the bag filter with the device; set the blast furnace gas condition in the outlet pipeline of the dry coarse dust collector, The dechlorination agent is ground to obtain a larger specific surface area, and is directly sprayed into the blast furnace gas pipeline by powder spraying for dechlorination reaction. Adopting the technical scheme of the invention, the one-time investment is small, the floor area is small, the system operation is simple, and the maintenance is convenient; the process of the invention can effectively improve the uniformity and adequacy of the contact between the dechlorination agent and the blast furnace gas, and improve the effect of dry dechlorination , the heat loss of blast furnace gas is low, and it does not affect the subsequent use of TRT.

Owner:BEIJING PEKING UNIV PIONEER TECH

Combined cooling, heating and power supply system and method based on adsorption heat pump using coal-fired flue gas

ActiveCN113324348BDoes not affect power generation efficiencyStable supplyMechanical apparatusHeat pumpsWater storage tankHeat pump

The invention relates to a combined cooling, heating and power supply system and method based on an adsorption heat pump using coal-fired flue gas, including a coal-fired flue gas pipeline, an adsorption heat pump unit, a hot water supply pipe, and a circulating air channel; the coal-fired flue gas The pipeline is connected to the first heat exchanger, and the water outlet of the second heat exchanger is connected to the hot water tank; the first heat exchanger, the second heat exchanger, the first adsorption bed, and the second adsorption bed are connected by a circulating heat source The working medium in the first adsorption bed, the second adsorption bed, the condenser and the evaporator forms a circulation through the medium flow pipe; the hot water tank is also connected to the water outlet of the condenser, the water supply pipe and the third water exchange Heater; the circulating air passage is connected to the third heat exchanger, the water inlet of the evaporator is connected to the third heat exchanger, and the water outlet of the evaporator is connected to the cold water tank. The invention can use the high-temperature flue gas produced by coal combustion in stages to supply domestic hot water, heating and cooling, and is equipped with a water storage tank to realize stable heating / cooling functions during peak periods.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com