Combined cooling, heating and power system and method based on adsorption type heat pump and utilizing coal-fired flue gas

A technology of combined cooling, heating and power, and adsorption heat pump, which is applied in the field of heat pump and refrigeration, and can solve the problems of difficulty in installation and maintenance of absorption units, high requirements on exhaust gas temperature, and difficulty in regeneration of absorption heat pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

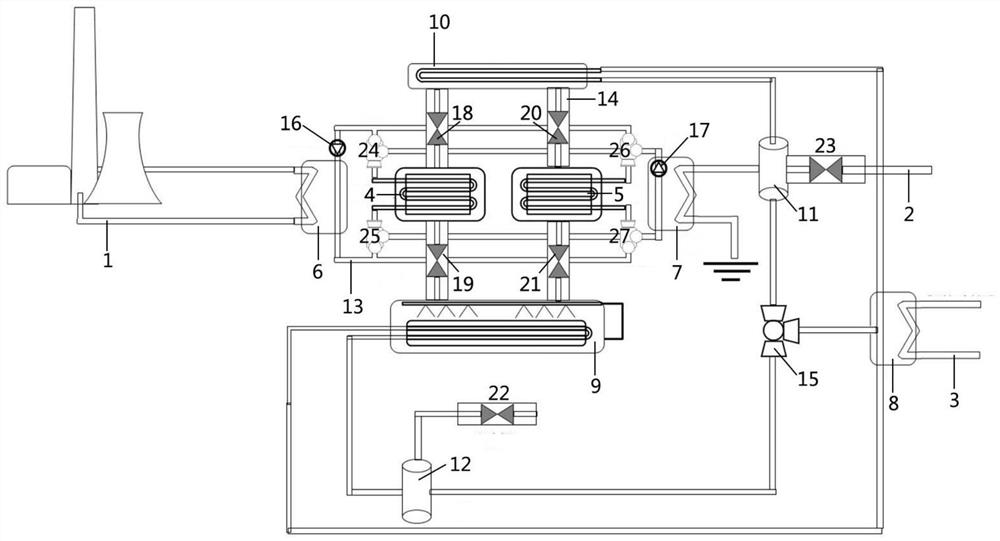

[0036] Example: see attached figure 1 , a combined cooling, heating and power supply system using coal-fired flue gas based on an adsorption heat pump, including a coal-fired unit flue gas pipeline 1, an adsorption heat pump unit, a hot water supply pipe 2, a hot water tank 11, a cold water tank 12 and a circulating gas Channel 3, the temperature of the flue gas in the flue gas pipeline 1 of the coal-fired unit is 110°C to 130°C.

[0037]The adsorption heat pump unit includes a first adsorption bed 4, a second adsorption bed 5, a first heat exchanger 6, a second heat exchanger 7, an evaporator 9 and a condenser 10; the coal-fired unit flue gas pipeline 1 Connected to the first heat exchanger 6, the water outlet of the second heat exchanger 7 is connected to the hot water tank 11, and the water inlet of the second heat exchanger 7 is connected to an external water source to supplement the circulation consumed during hot water supply water; the first heat exchanger 6, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com