Preparation method of composite soda blocking collector plate

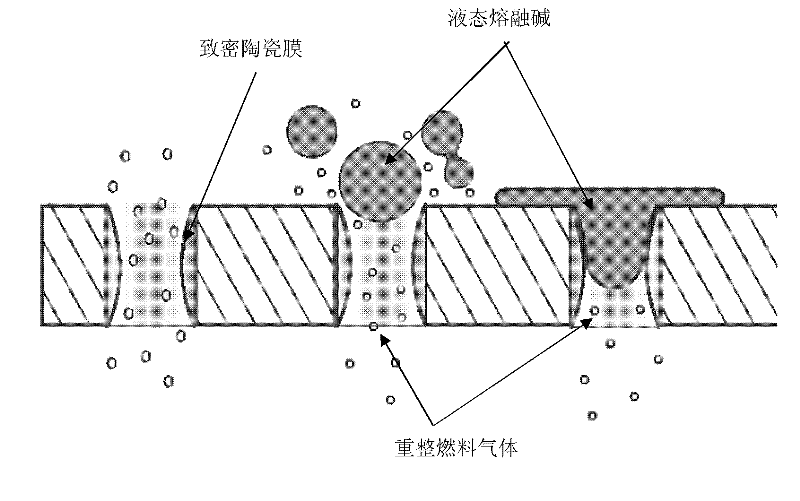

A current collecting plate and alkali blocking technology, which is applied to fuel cell parts, fuel cells, electrical components, etc., can solve the problems of poor repeatability, short running time, and poor alkali blocking effect, so as to reduce the loss and improve the The effect of operating life and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of alkali-resistance composite collector plate

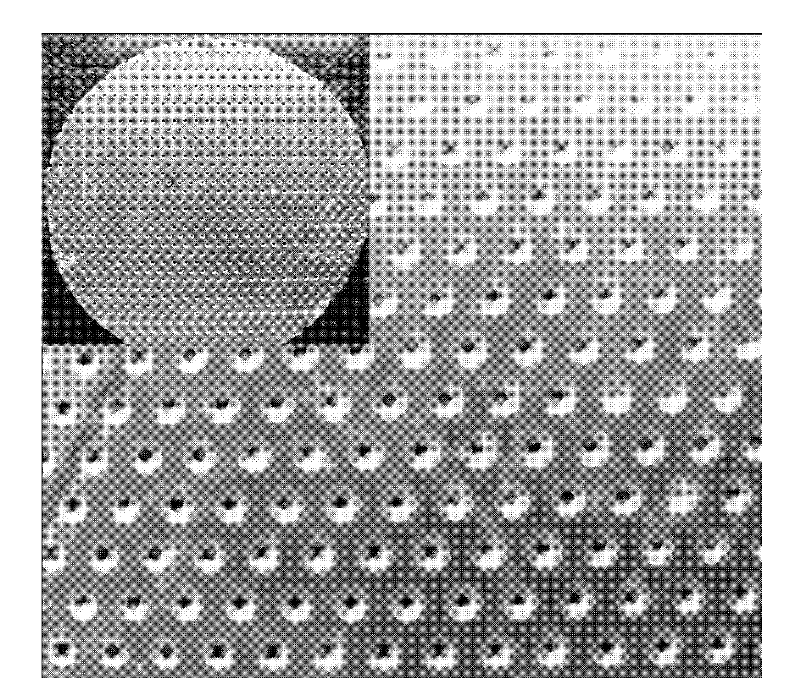

[0031] Treatment of the porous stainless steel plate: use 304 porous stainless steel as the substrate, prepare a collector plate with a diameter of 40 mm, a pore diameter of 0.3 mm, and a thickness of 0.5 mm, tie the edge of the porous stainless steel plate with a polytetrafluoroethylene tape, and use HNO3 solution (1mol / L), NaOH solution (1mol / L), deionized water and absolute ethanol were cleaned in an ultrasonic cleaner, and then stored in absolute ethanol.

[0032] Suspension preparation: Add sintered colloidal ceramic powder (AREMCO) into deionized water to prepare 30ml of suspension with a concentration of 0.35-0.52g / mL, shake evenly with an oscillator and add 0.5wt%-1wt% of silane coupling Agent (AP-TMS) and alkaline catalyst (KF), fully shaken by ultrasonic cleaning agent, mixed evenly, and then pulled at room temperature.

[0033] Pulling film formation: After the treated stainless steel ca...

Embodiment 2

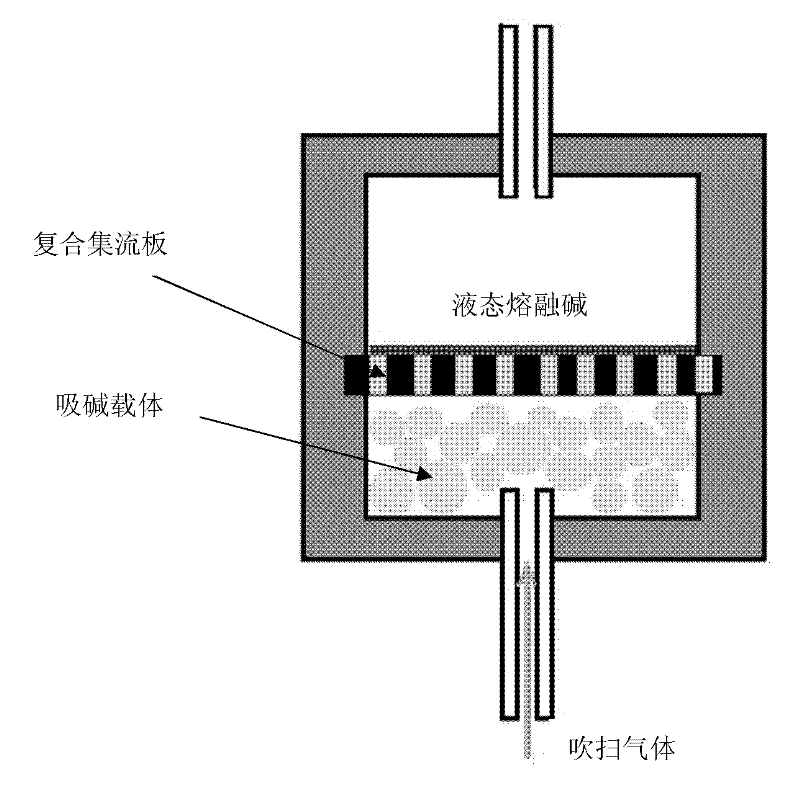

[0035] Embodiment 2: test of reforming reaction containing alkali outside the pool

[0036] The purpose of this application test is to detect the ability of the alkali-resistant composite collector plate to block liquid molten carbonate. By simulating the battery structure and environment, the test is carried out in a special stainless steel tubular reactor. First, weigh 4 grams of porous alumina pellets and place them in the lower chamber of the reaction tube, and then place the current collector plate (with a pore diameter of 2 mm) used in the traditional fuel cell, the blank porous stainless steel current collector plate (with a pore diameter of 0.35 mm) and the resistor Alkali composite current collectors are respectively placed in the reaction tube, the single-layer electrolyte diaphragm (lithium metaaluminate film) used in the battery is cut to the same size as the current collector, and then the mixed alkali of 62mol% Li2CO3 and 38mol% K2CO3 2 grams of powder was placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com