Anti-potential induced degradation (PID) effect photovoltaic component

A photovoltaic module and effect technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of high cost and potential safety hazards, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

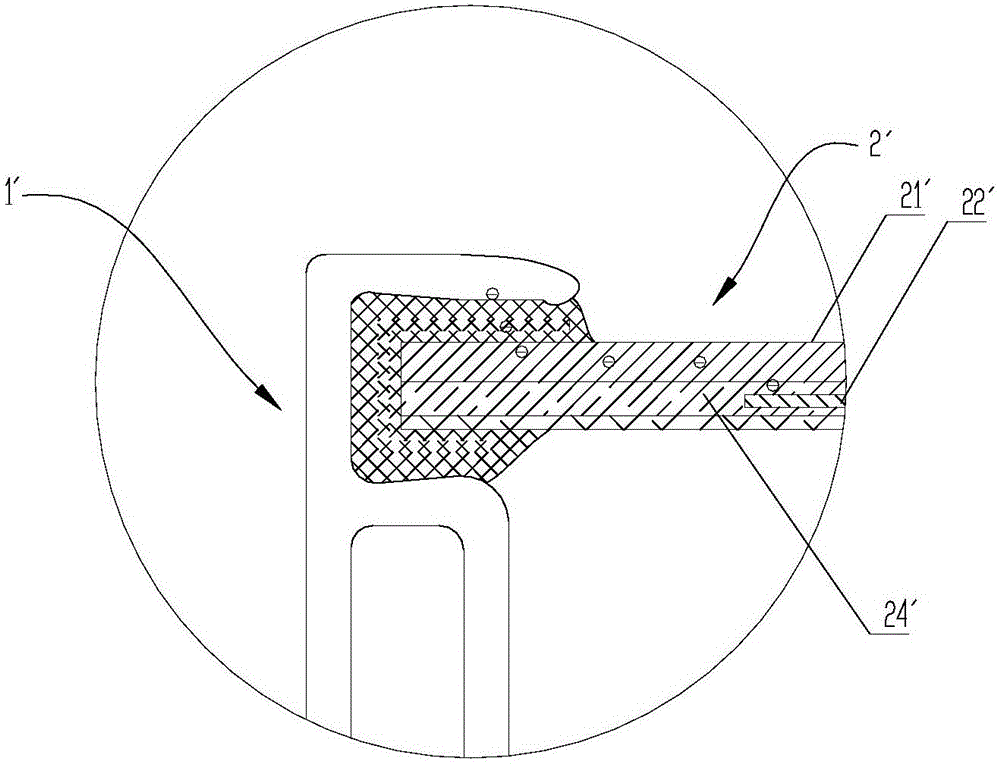

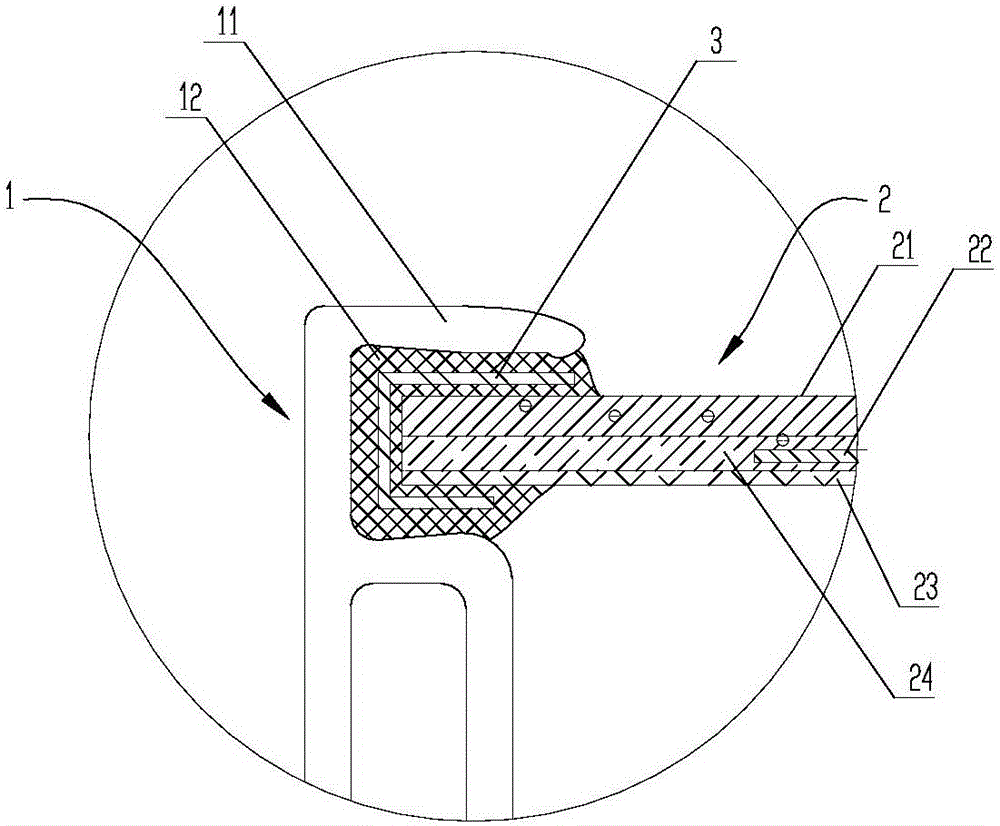

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0029] Such as figure 2 As shown, this embodiment provides a photovoltaic module that is resistant to the PID effect, and is especially suitable for conventional components in a photovoltaic power plant system, which includes a frame 1 and a photovoltaic laminated module 2 arranged in the frame 1, wherein the frame 1 It is an aluminum frame, and the photovoltaic laminated assembly 2 includes glass 21, battery sheet 22 and back plate 23 arranged in sequence. An insulating structure 3 is arranged between them.

[0030] Through the arrangement of the insulating structure 3 , electron transfer between the frame 1 and the photovoltaic laminated module 2 can be blocked, so as to achieve the effect of anti-PID effect. This anti-PID effect method will not affect the power generation efficiency of the pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com