System preventing low-temperature corrosion of power station boiler

A technology for low-temperature corrosion and power plant boilers, applied in the direction of combustion methods, feed water heaters, preheating, etc., can solve the problems of exhaust gas temperature rise and seriousness, and achieve the effects of preventing low-temperature corrosion, improving boiler efficiency, and avoiding low-temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

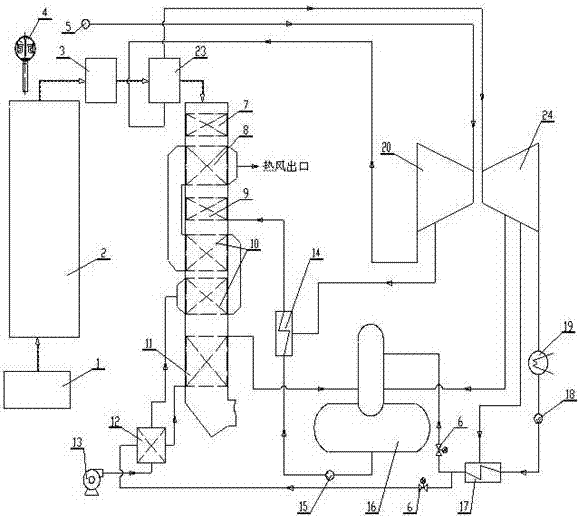

[0026] Specific implementation mode one: combine figure 1 Explain, a system for preventing low-temperature corrosion of power plant boilers, for high-pressure and above condensing-type primary reheat generating sets with a feedwater temperature above 200°C, the system includes a combustion device 1, a furnace 2, a superheater 3, a drum 4, Steam header 5, regulating valve 6, high temperature economizer 7, high temperature air preheater 8, low temperature economizer 9, medium temperature air preheater 10, flue gas feed water heater 11, gas water air preheater 12 , fan 13, high pressure heater 14, boiler feed water pump 15, deaerator 16, low pressure heater 17, condensate pump 18, condenser 19, steam turbine high pressure cylinder 20, reheater 23, steam turbine medium and low pressure cylinder 24.

[0027] The air required for combustion enters the air-water air preheater 12 through the fan 13, is heated to about 70°C-100°C, and then is further heated to the design temperature of...

specific Embodiment approach 2

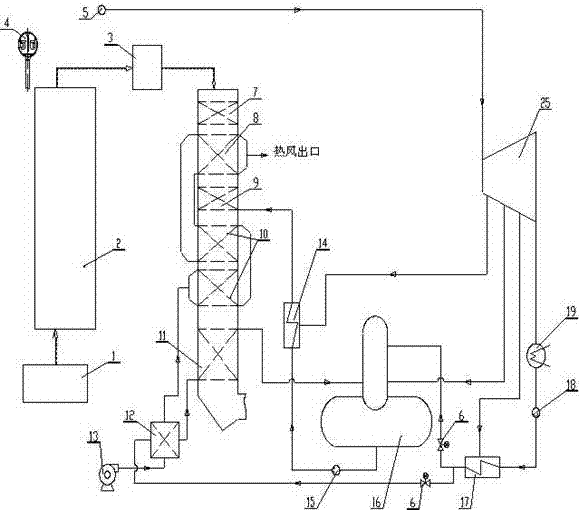

[0029] Specific implementation mode two: combination figure 2 Explain, a system for preventing low-temperature corrosion of power plant boilers, for high-pressure and above condensing steam generator sets with a feedwater temperature above 200°C, the system includes a combustion device 1, a furnace 2, a superheater 3, a drum 4, and a steam collector Box 5, regulating valve 6, high temperature economizer 7, high temperature air preheater 8, low temperature economizer 9, medium temperature air preheater 10, flue gas feed water heater 11, gas water air preheater 12, fan 13 , High pressure heater 14, boiler feed water pump 15, deaerator 16, low pressure heater 17, condensate water pump 18, condenser 19, steam turbine 25.

[0030] The air required for combustion enters the air-water air preheater 12 through the fan 13, is heated to about 70°C-100°C, and then is further heated to the design temperature of the hot air by the medium-temperature air preheater 10 and the high-temperatu...

specific Embodiment approach 3

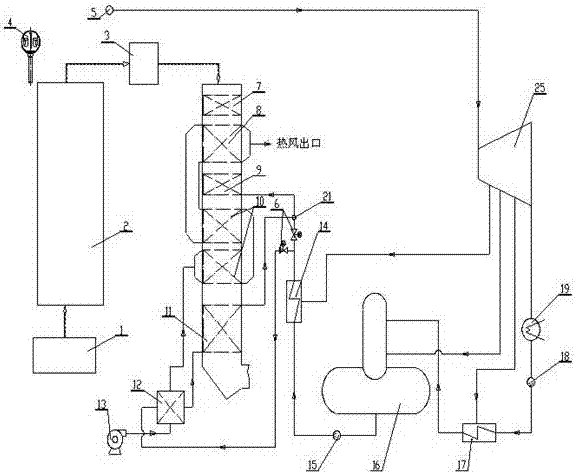

[0032] Specific implementation mode three: combination image 3 Description, a low-temperature corrosion prevention system for utility boilers, for condensing steam generating units with a feed water temperature of 145°C to 155°C and below high pressure, the system includes a combustion device 1, a furnace 2, a superheater 3, a drum 4, and a steam header 5. Control valve 6, high temperature economizer 7, high temperature air preheater 8, low temperature economizer 9, medium temperature air preheater 10, flue gas feed water heater 11, gas water air preheater 12, fan 13, High pressure heater 14, boiler feed water pump 15, deaerator 16, low pressure heater 17, condensate water pump 18, condenser 19, mixing header 21, steam turbine 25.

[0033] The air required for combustion passes through the fan 13 and enters the air-water air preheater 12 to be heated to about 70°C-100°C, and then passes through the medium-temperature air preheater 10 and high-temperature air preheater 8 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com