Double-sided power generation glass assembly and preparation method thereof

A glass and component technology, applied in the field of double-sided power generation glass components and their preparation, can solve the problems of junction box cables affecting the appearance, poor sound insulation performance, insufficient strength, etc., achieving excellent photoelectric transmission effect, saving resources, and improving power generation. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the above-mentioned double-sided power generation glass assembly, which includes the following steps: preparation of the first glass substrate, preparation of the power generation film layer, electrode connection, coating of butyl glue, preparation of the power generation glass component, light emitting element and Sound insulation material filling, hollow installation, installation of junction box.

[0048] Specifically, the preparation process of the first glass substrate is as follows: the anti-reflection film gel is sprayed on the bottom of the first glass substrate, and is initially heated and cured at 150° C. for 1 hour, heated and cured at 500° C. for 30 minutes, and dissipated. The first glass substrate of anti-reflection film coating; The anti-reflection film gel is SiO 2 gel; the SiO 2 Gel made of SiO 2 Mixed with additives; by volume percentage, the SiO 2 SiO in gel 2 The content is 3%; the auxili...

Embodiment 1

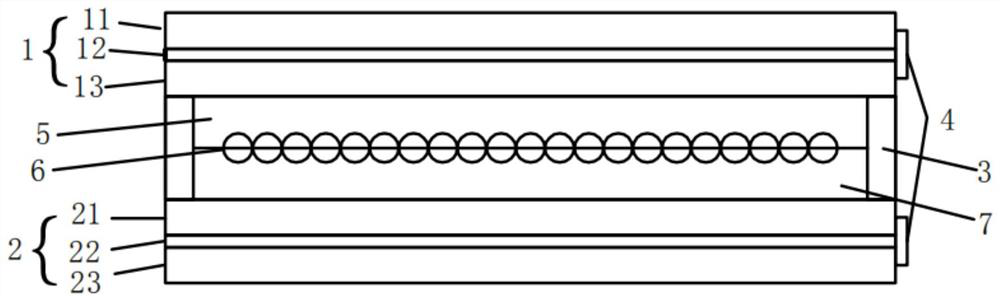

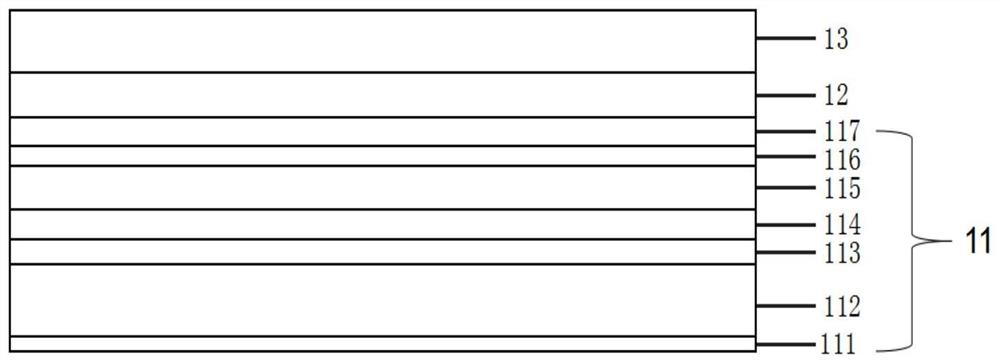

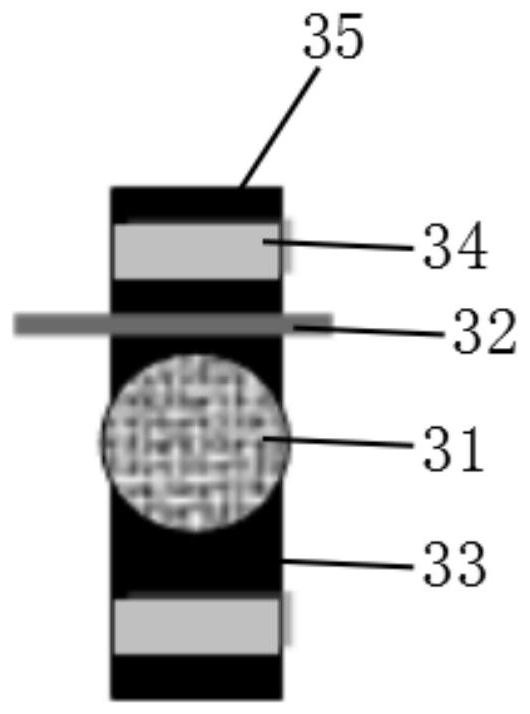

[0058] A double-sided power generation glass assembly, such as figure 1 As shown, it includes: power generation glass component I1, spacer 3, power generation glass component II2 and junction box 4. The power generation glass component I1 and power generation glass component II2 are layered structures, and the upper and lower sides of the spacer 3 are respectively connected to The power generation glass component I1 and the power generation glass component II2, a 12 mm hollow layer 5 is formed between the power generation glass component I1 and the power generation glass component II2 and the spacer bar 3, and the power generation glass component I1 and the power generation glass component II2 are formed by close One side of the hollow layer 5 is successively outwards semi-tempered glass 13 and 21 with a thickness of 6mm, PVB adhesive film 12 and 22 with a thickness of 0.76mm, and power generation film layers 11 and 21 with a thickness of 3.2mm. The semi-tempered glass and the...

Embodiment 2

[0072] Same as Example 1, the only difference is that the thickness of hollow layer 5 is 13mm, the thickness of semi-tempered glass 13 and 21 is 8mm, the thickness of PVB film 12 and 22 is 1.14mm, and the thickness of butyl rubber is 0.76mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com