Vertical take-off unmanned aerial vehicle auxiliary take-off system

A vertical take-off, unmanned aerial vehicle technology, applied in control/adjustment systems, non-electric variable control, instruments, etc., can solve the problems of aircraft take-off and landing damage, violent ups and downs of aircraft height, rollover, etc., to achieve fast and safe take-off, easy effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

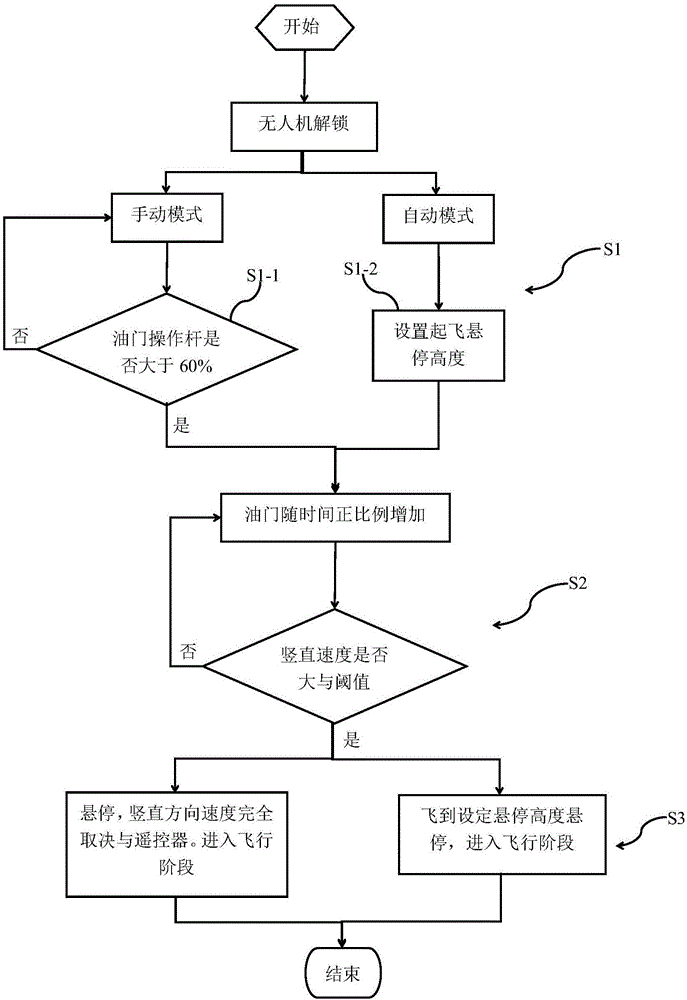

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to describe the vertical take-off UAV assisted take-off system of the present invention in detail.

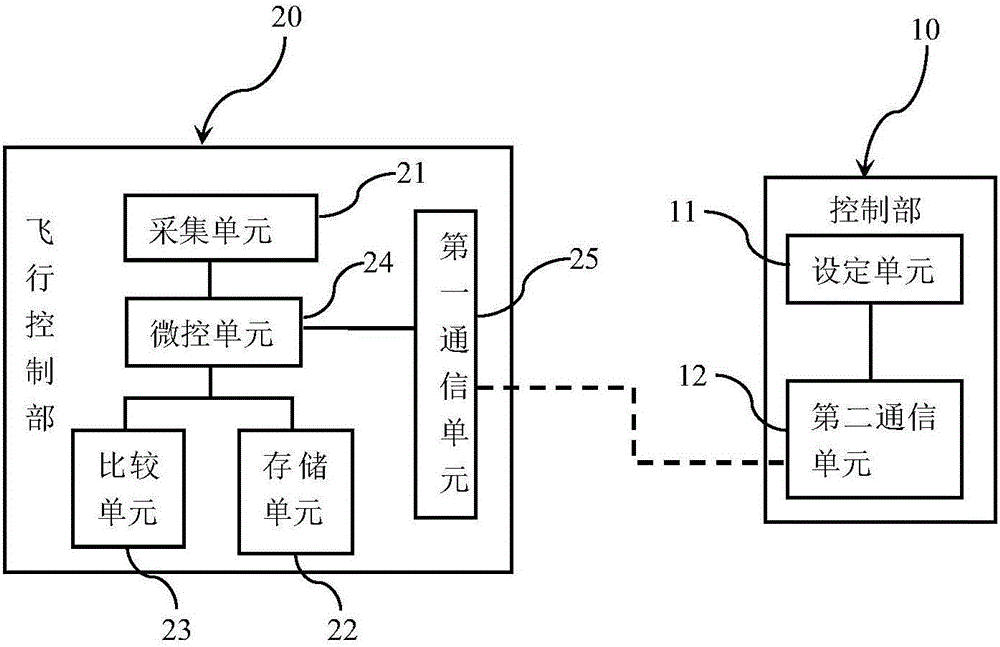

[0026] Such as figure 1 As shown, the auxiliary take-off system 100 for vertical take-off UAV includes: a control unit 10 and a flight control unit 20 .

[0027] The control unit 10 is used to control the flight of the drone, and the control unit 10 is a remote controller or a ground station. The control unit 10 includes: a setting unit 11 and a first communication unit 12 .

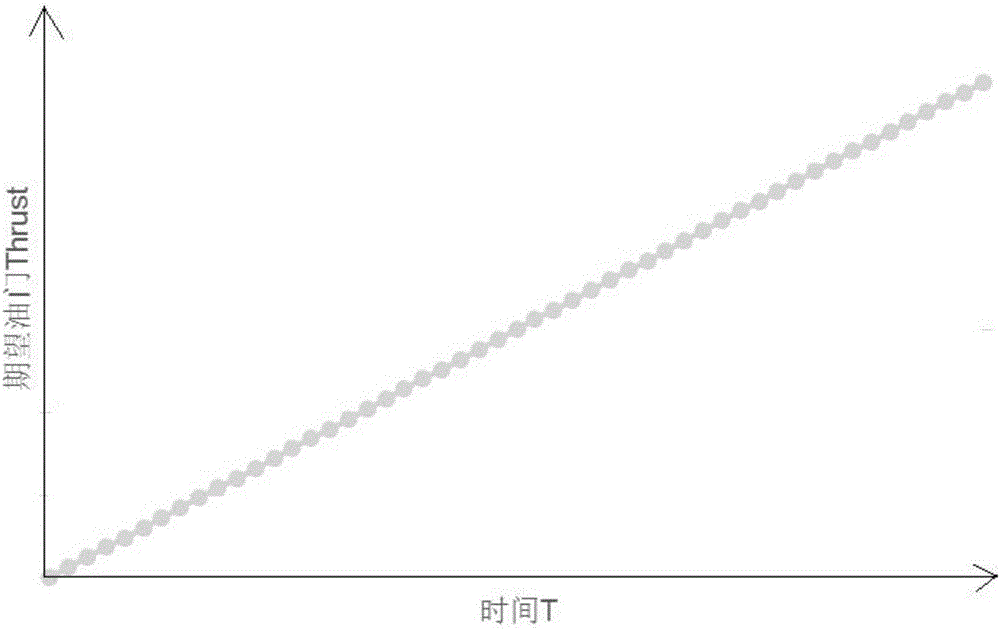

[0028] The setting unit 11 is used for setting the control signal. The control signal includes: the way to start each rotor of the drone, the size of the throttle, etc., which are used to control the flying speed, hover, dive, etc. of the drone. The first communication unit 12 is used for communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com