Solar laminated modules with center-converging grid electrodes

A laminated module and solar energy technology, which is applied in the field of solar cells, can solve the problems of high cost, large consumption of silver paste and conductive adhesive, etc., achieve the effects of convenient operation, simple bonding and fixing methods, and solve the problem of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

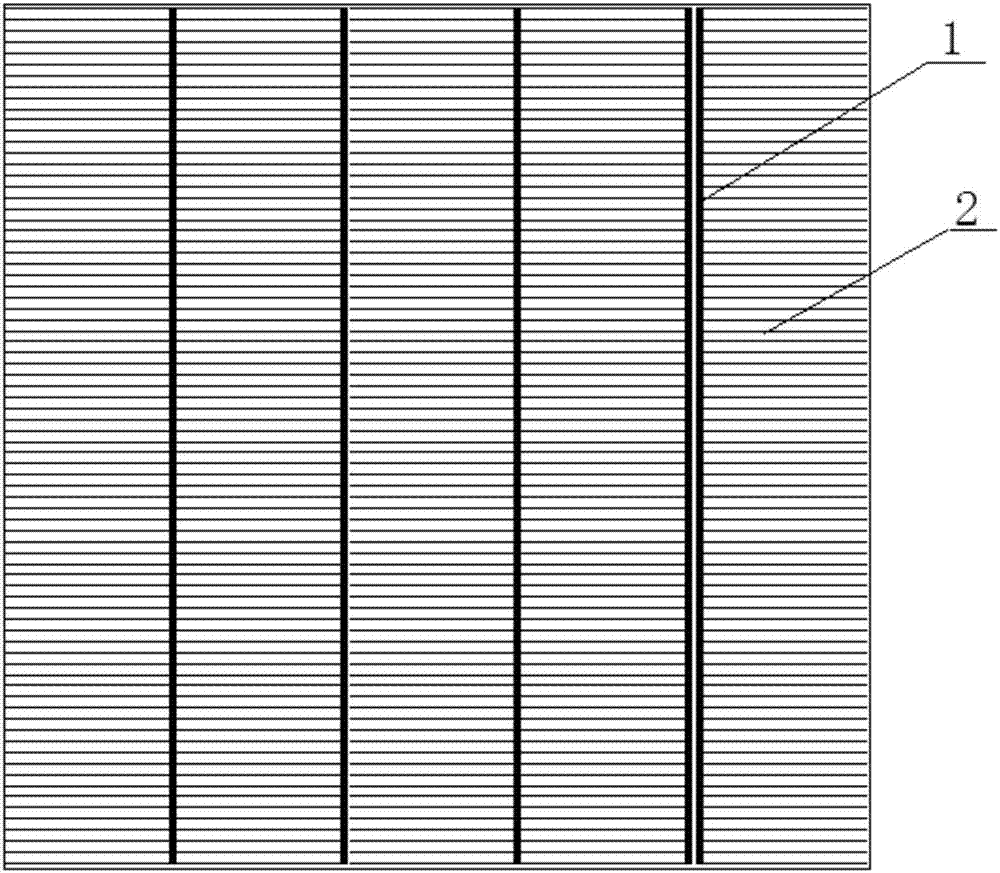

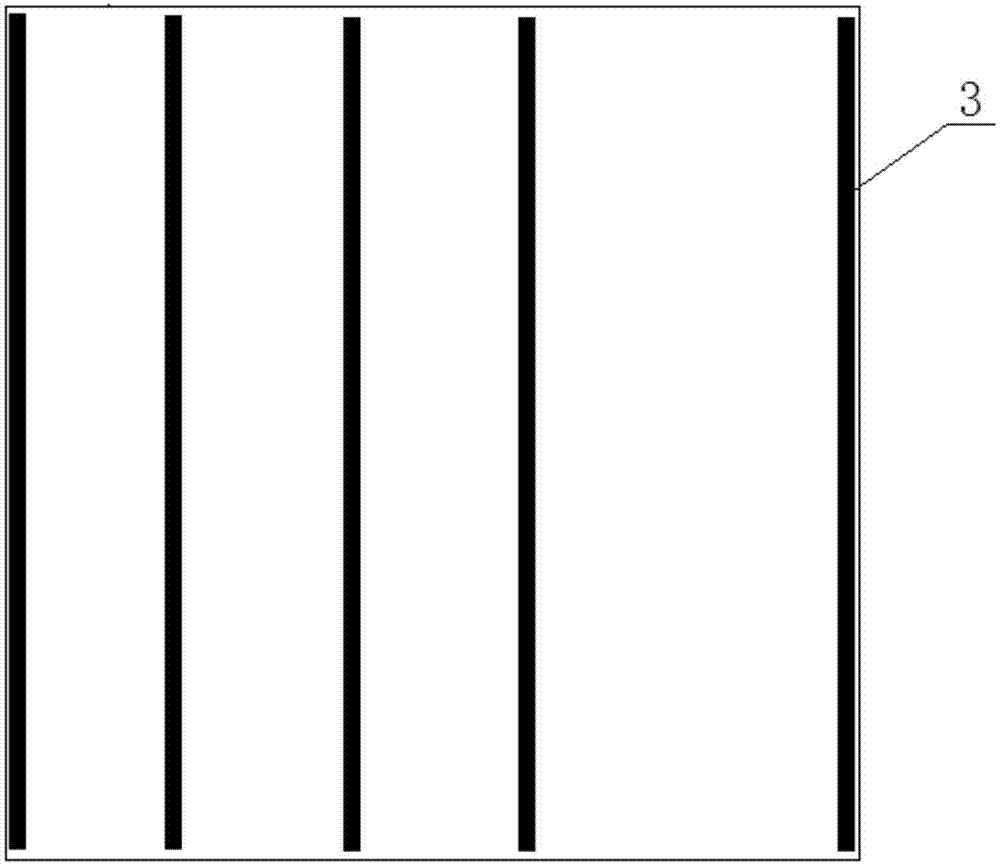

[0050] like Figure 4 and Figure 5 As shown, the cell is divided into several sub-cells. The auxiliary grid lines on the front of each sub-cell are divided into several groups. On the front of the sub-battery, each group of sub-grid lines 9 converges toward the center to converge current to their respective main electrode points 10, and each main electrode point 10 is distributed along one long side of the sub-cell. In one-to-one correspondence with the main electrode points 10 on the front of the battery, the electrodes on the back of the battery also exist in the form of main electrode points 17 . For the same sub-battery, the main electrode points 10 on the front side and the main electrode points 17 on the back side are respectively distributed along two opposite long sides.

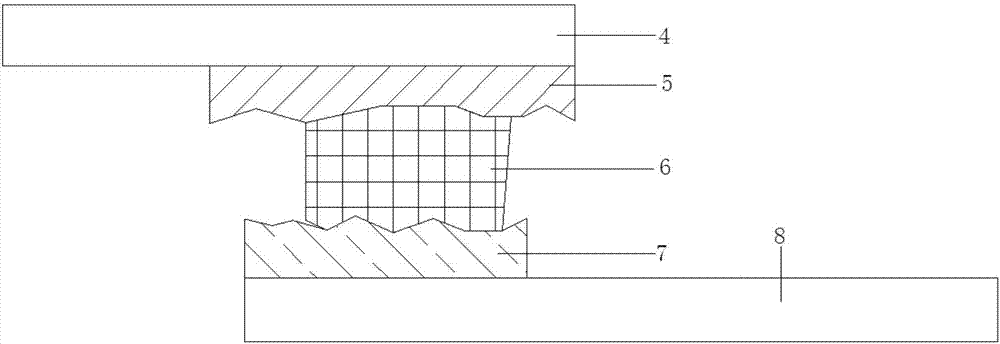

[0051] like Image 6 and Figure 7 As shown, in the laminated assembly, the edges of adjacent sub-cells overlap, and the front main electrode point 10 of the first sub-cell 4 and the back main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com