Silver-directed recovery mineral processing method in the separation process of copper-lead-zinc sulfide ore

A technology of separation process and beneficiation method, applied in solid separation, flotation and other directions, can solve the problem of low silver recovery rate, and achieve the effect of improving silver recovery rate, improving comprehensive utilization rate of silver resources, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

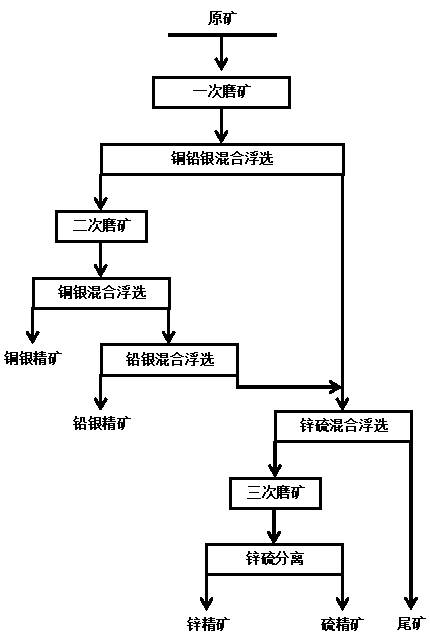

[0040]The raw ore of this embodiment is taken from a certain silver-containing copper-lead-zinc polymetallic sulfide ore in Inner Mongolia. t, the mass percentage of sulfur is 6.12%. Process flow chart such as figure 1 As shown, the beneficiation steps are as follows:

[0041] S1. Raw ore is ground to -0.074mm at one time, accounting for 42%;

[0042] S2. The ore pulp after the primary grinding in step S1 is subjected to copper-lead-silver mixed flotation, calculated on the basis of 1 ton of raw ore, in the copper-lead-silver mixed flotation, sodium carbonate and zinc sulfate are combined as regulators in a mass ratio of 1:1, and the combined amount It is 2600 grams, adjust the pulp pH value to be 9, and the dosage of ammonium butyl ammonium black medicine is 40 grams; Obtain copper-lead-silver mixed concentrate and copper-lead-silver mixed flotation tailings respectively;

[0043] S3. The copper-lead-silver mixed concentrate obtained in step S2 is subjected to secondary gr...

Embodiment 2

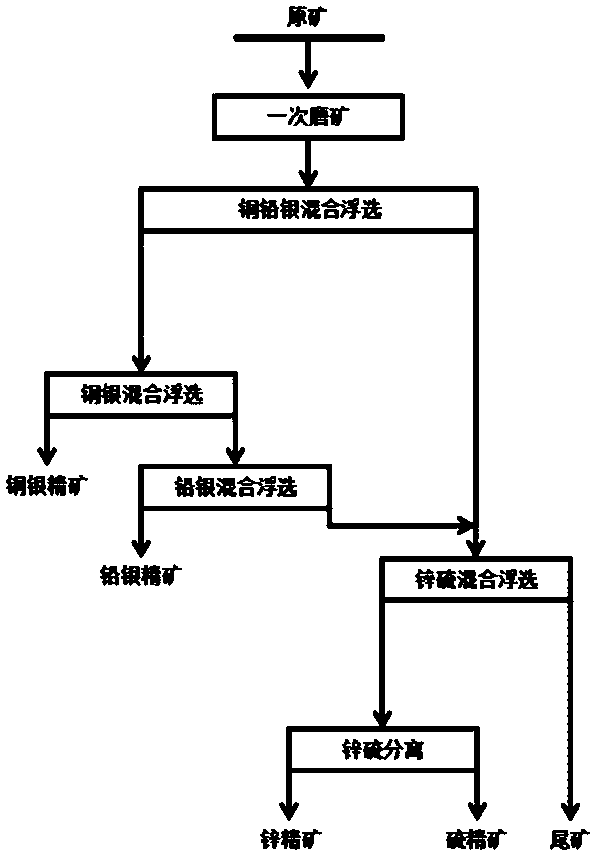

[0049] The raw ore of this embodiment is taken from a certain silver-containing copper-lead-zinc polymetallic sulfide ore in Yunnan. t, the mass percentage of sulfur is 10.96%. Process flow chart such as figure 2 As shown, the beneficiation steps are as follows:

[0050] S1. Raw ore is ground to -0.074mm at one time, accounting for 80%;

[0051] S2. The ore pulp after the primary grinding in step S1 is subjected to copper-lead-silver mixed flotation, calculated on the basis of 1 ton of raw ore, in copper-lead-silver mixed flotation, sodium carbonate and zinc sulfate are combined as regulators in a mass ratio of 4:1, and the combined amount It is 2500 grams, adjust the pulp pH value to be 9, and the dosage of butylammonium black medicine is 50 grams; Obtain copper-lead-silver mixed concentrate and copper-lead-silver mixed flotation tailings respectively;

[0052] S3. The copper-lead-silver mixed concentrate obtained in step S2 is directly subjected to copper-silver mixed fl...

Embodiment 3

[0058] The raw ore of this embodiment is taken from a certain silver-containing copper-lead-zinc polymetallic sulfide ore in Yunnan. t, the mass percentage of sulfur is 11.25%. The beneficiation steps are as follows:

[0059] S1. Raw ore is ground to -0.074mm at one time, accounting for 70%;

[0060] S2. The ore pulp after the primary grinding in step S1 is subjected to copper-lead-silver mixed flotation, calculated on the basis of 1 ton of raw ore, in copper-lead-silver mixed flotation, sodium carbonate and zinc sulfate are combined as regulators in a mass ratio of 1:1, and the combined amount It is 3000 grams, adjust the pulp pH value to be 9, and the dosage of butylammonium black medicine is 50 grams; Obtain copper-lead-silver mixed concentrate and copper-lead-silver mixed flotation tailings respectively;

[0061] S3. The copper-lead-silver mixed concentrate obtained in step S2 is secondarily ground to -0.043mm and accounts for 75%, and then copper-silver mixed flotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com