Silver guide recovery beneficiation method in table flotation sulphide ore bulk concentrate separation process

A technology of mixing concentrates and floating sulfide ores, which is applied in flotation, solid separation, etc., can solve the problems of insufficient total silver recovery rate, no silver-oriented recovery reports and application examples, etc., to improve comprehensive utilization rate, economical Significant benefit and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this embodiment, the raw ore is taken from the mixed concentrate of Taiwan Fu sulfide ore produced by a tin polymetallic sulfide mine in Guangxi. The mass percentage of copper in the mixed concentrate of Tai Fu sulfide ore is 3.41%, and the mass percentage of molybdenum is 0.52%, the mass percentage of bismuth is 1.81%, the mass percentage of sulfur is 19.15%, and the mass content of silver is 350g / t.

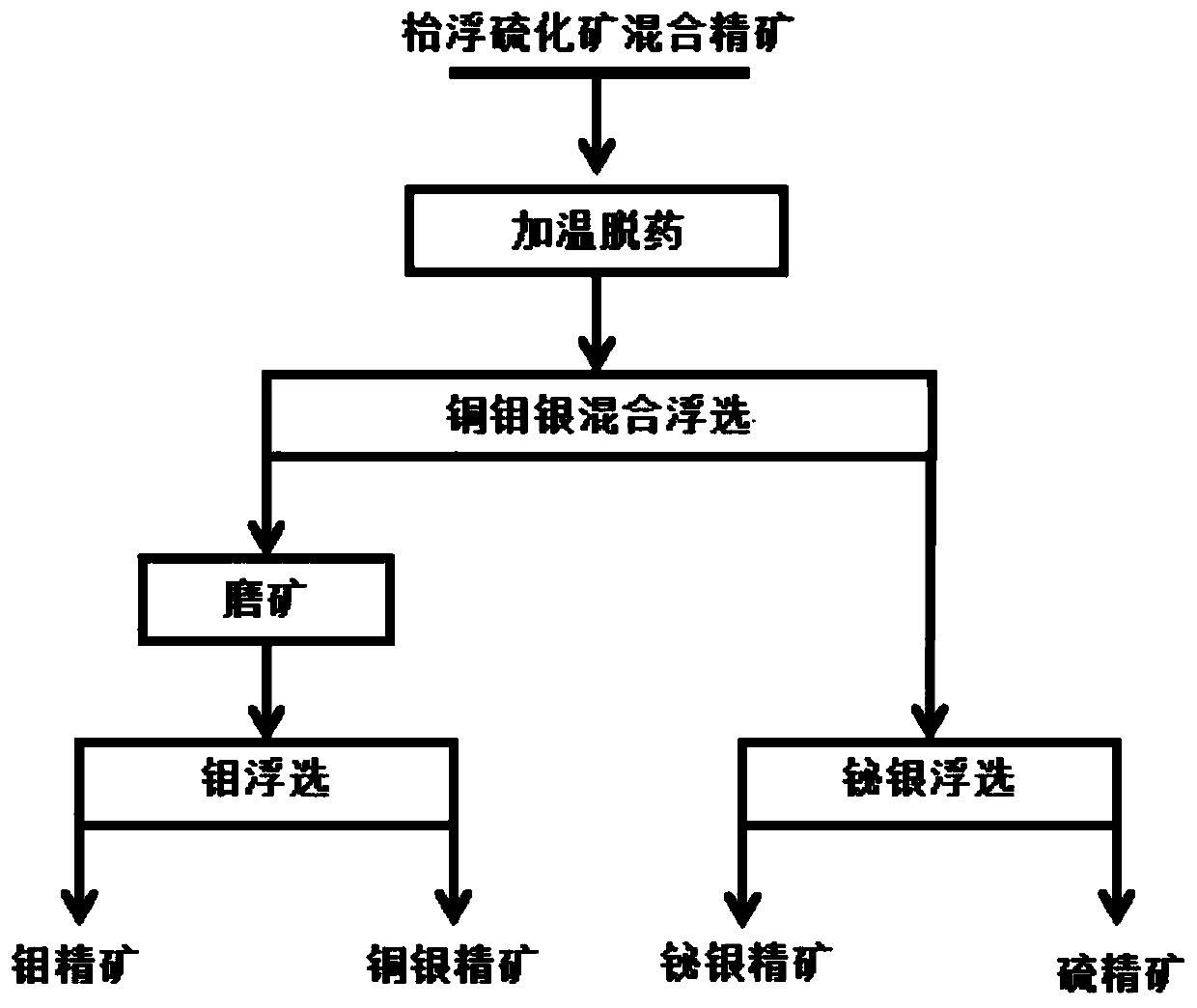

[0052] In this embodiment, the silver-directed recovery process in the separation process of Taiwan floating sulfide ore mixed concentrate is as follows:

[0053] S1. Heat the mixed concentrate of Taifu sulfide ore to 85°C, stir for 120 minutes, add water to adjust the slurry to a concentration of 34%, and obtain the slurry;

[0054] S2. The ore pulp after step S1 is heated and demedicated is carried out copper-molybdenum-silver mixed flotation, calculated according to the amount of mixed concentrate of 1 ton of Taiwan floating sulfide ore, the consumption of lime dur...

Embodiment 2

[0060] In this example, the raw ore is taken from the mixed concentrate of Taifu sulfide ore in the production of a tin polymetallic sulfide mine in Yunnan. The mass percentage of copper in the mixed concentrate of Taifu sulfide ore is 4.41%, and the mass percentage of molybdenum is 0.80%, the mass percentage of bismuth is 1.51%, the mass percentage of sulfur is 20.05%, and the mass content of silver is 380g / t.

[0061] In this embodiment, the silver-directed recovery process in the separation process of Taiwan floating sulfide ore mixed concentrate is as follows:

[0062] S1. Heat the mixed concentrate of Taifu sulfide ore to 80°C, stir for 100 minutes, add water to adjust the slurry to a concentration of 35%, and obtain the slurry;

[0063] S2. The ore slurry after step S1 is heated and demedicated is carried out copper-molybdenum-silver mixed flotation, calculated according to the amount of mixed concentrate of 1 ton of Taiwan floating sulfide ore, the consumption of lime d...

Embodiment 3

[0069] In this example, the raw ore is taken from the Taiwan Fu sulfide ore mixed concentrate in the production of a tungsten polymetallic sulfide mine in Guangdong. The mass percentage of copper in the Tai Fu sulfide ore mixed concentrate is 3.21%, and the mass percentage of molybdenum 0.44%, the mass percentage of bismuth is 1.71%, the mass percentage of sulfur is 19.15%, and the mass content of silver is 330g / t.

[0070] In this embodiment, the silver-directed recovery process in the separation process of Taiwan floating sulfide ore mixed concentrate is as follows:

[0071] S1. Heat the mixed concentrate of Taifu sulfide ore to 80°C, stir for 90 minutes, add water to adjust the slurry to a concentration of 33%, and obtain the slurry;

[0072] S2. The ore pulp after step S1 is heated and demedicated is carried out copper-molybdenum-silver mixed flotation, calculated according to the amount of mixed concentrate of 1 ton of Taiwan floating sulfide ore, the consumption of lime ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com