A kind of silver-guided recovery beneficiation method in bismuth-sulfur separation process

A technology of separation process and beneficiation method, applied in the direction of solid separation, flotation, grain processing, etc., can solve the problem that there are no reports and application examples of silver-oriented recovery, no consideration of silver direction and recovery, and no consideration of silver recovery conditions and other issues, to achieve the effect of improving the comprehensive utilization rate, significant economic benefits, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In the present embodiment, the raw ore is taken from a certain silver-bismuth-containing polymetallic sulfide ore in Yunnan, and the mass percentage of bismuth in the raw ore is 0.36%, the mass percentage of silver is 73 g / t, and the mass percentage of sulfur is 8.23%.

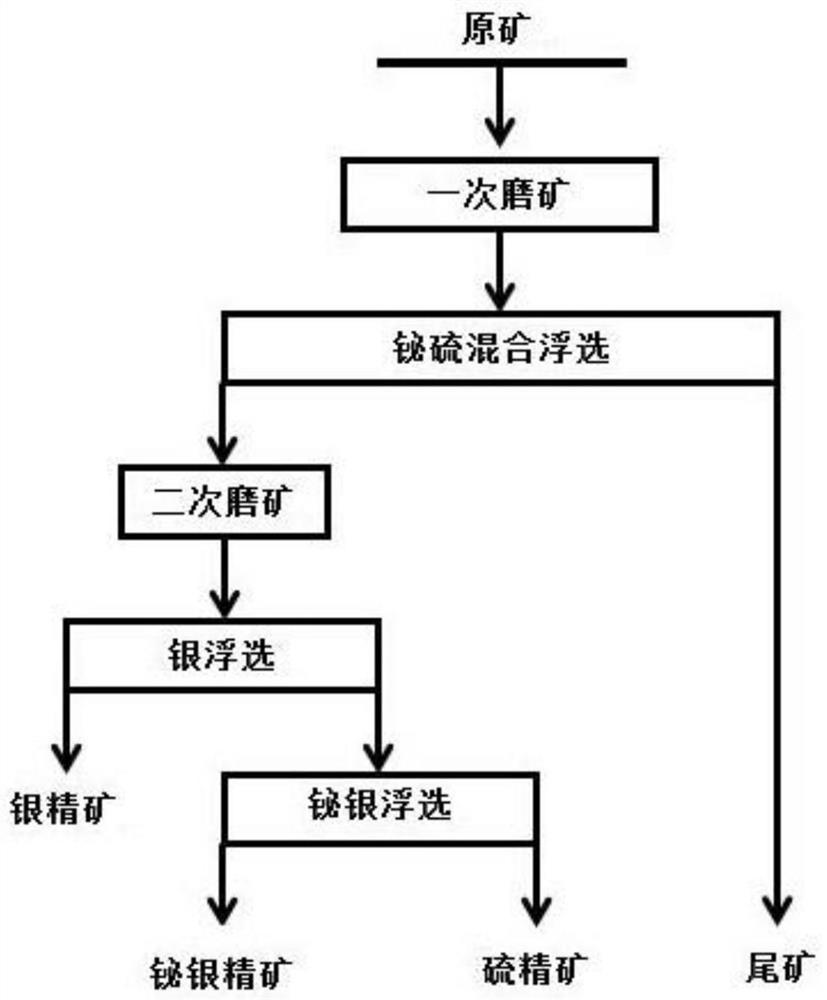

[0050] In the present embodiment, the process flow diagram of silver-oriented recovery in the bismuth-sulfur separation process is as follows: figure 1 As shown, the beneficiation steps are as follows:

[0051] 1) The raw ore is ground to -0.074mm for 70%;

[0052] 2) Carry out bismuth-sulfur mixed flotation through step 1) once grinding the ore pulp, and calculate by 1 ton of raw ore, the consumption of butyl xanthate during the bismuth-sulfur mixed flotation is 150 grams, and the consumption of pine oil is 80 grams, to obtain Bismuth-sulfur mixed concentrate and bismuth-sulfur flotation tailings;

[0053] 3) carrying out the secondary grinding of step 2) gained bismuth-sulfur mixed concentrate to -0...

Embodiment 2

[0058] In the present embodiment, the raw ore is taken from a certain silver-containing bismuth polymetallic sulfide ore in Hunan, and the mass percentage of bismuth in the raw ore is 0.45%, the mass percentage of silver is 120 g / t, and the mass percentage of sulfur is 11.52%.

[0059] In the present embodiment, the process flow diagram of silver-oriented recovery in the bismuth-sulfur separation process is as follows: figure 1 As shown, the beneficiation steps are as follows:

[0060] 1) The raw ore is ground to -0.074mm for 85%;

[0061] 2) Carry out bismuth-sulfur mixed flotation through step 1) once grinding the ore pulp, and calculate by 1 ton of raw ore, the consumption of butyl xanthate during bismuth-sulfur-silver mixed flotation is 200 grams, and the consumption of pine oil is 80 grams , to obtain bismuth-sulfur mixed concentrate and bismuth-sulfur flotation tailings;

[0062] 3) carrying out the secondary grinding of step 2) gained bismuth-sulfur mixed concentrate ...

Embodiment 3

[0067] In the present embodiment, the raw ore is taken from a polymetallic sulfide ore containing silver and bismuth in Guangdong, and the mass percentage of bismuth in the raw ore is 0.25%, the mass percentage of silver is 65g / t, and the mass percentage of sulfur is 7.52%.

[0068] In the present embodiment, the process flow diagram of silver-oriented recovery in the bismuth-sulfur separation process is as follows: figure 1 As shown, the beneficiation steps are as follows:

[0069] 1) The raw ore is ground to -0.074mm for 75%;

[0070] 2) carry out bismuth-sulfur mixed flotation through step 1) once grinding the ore pulp, and calculate by 1 ton of raw ore, the consumption of butyl xanthate during the mixed flotation of bismuth-sulfur-silver is 120 grams, and the consumption of pine oil is 60 grams, Obtain bismuth-sulfur mixed concentrate and bismuth-sulfur flotation tailings;

[0071] 3) carrying out the secondary grinding of step 2) gained bismuth-sulfur mixed concentrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com