BIPV intelligent chip photovoltaic module and packaging process thereof

A technology of smart chips and photovoltaic modules, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of system power generation decline, output power decline, and component loss, etc., to increase power generation and reduce battery stalls , The effect of high power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

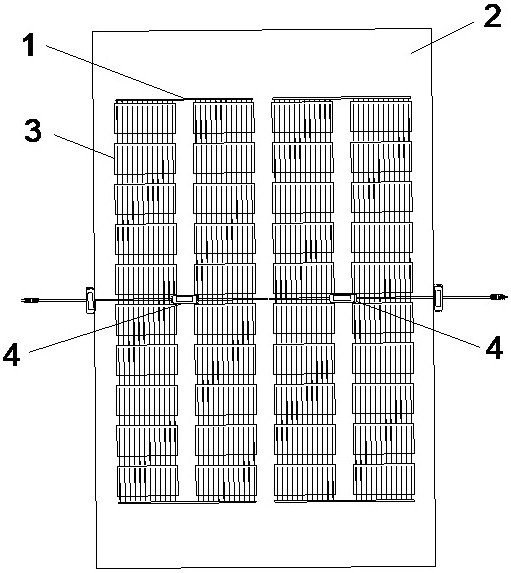

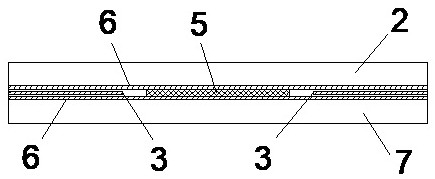

[0037] see Figure 1-3 , a kind of BIPV smart chip photovoltaic assembly that the present invention relates to, it comprises BIPV assembly 1, front plate toughened glass 2, smart chip box 4 and back plate tempered glass 7, described BIPV assembly 1 comprises 4 strings of battery strings, each string of batteries The string is composed of 10 solar cells 3 connected in series, that is, a total of 40 solar cells 3. A smart chip box 4 is arranged between the two adjacent battery strings on the left. The room also has a smart chip box 4.

[0038] The front side of the battery string array of the BIPV module 1 is connected to the front tempered glass 2 through the adhesive film 6, and the back side is connected to the back tempered glass 7 through the adhesive film 6, and the adhesive film 6 is POE adhesive film or EVA adhesive film.

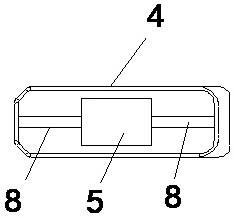

[0039] The smart chip box 4 is provided with a smart chip 5, the left end of the smart chip 5 is provided with a bus bar 8 extending out of the smar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com