Small photo-thermal combination solar power station

A solar energy and photothermal technology, applied in the field of solar energy application, can solve the problems of not being able to reduce the temperature of the components well, it is difficult to obtain economic benefits, and the heat collection is scattered, and achieves the effect of being beneficial to the collection and utilization, the structure is simple, and the heat loss is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

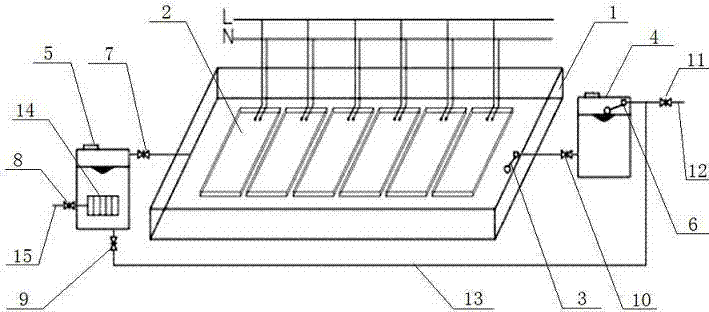

[0024] This embodiment provides a small solar power station with integrated light and heat, the structure of which is as follows: figure 1 As shown, it includes a shallow water tank 1 and a solar solar power generation assembly 2, and the shallow water tank 1 is made of heat insulating material. The bottom of one side of the shallow water tank 1 is centered with a water outlet, and the other side of the shallow water tank 1 is provided with a first ball float valve 3, which is connected to the cold water tank 4 and controls the water level of the shallow water tank 1.

[0025] The number of solar power generation components 2 is 5-30 pieces. The solar power generation components 2 are filling junction box components. The solar power generation components 2 are arranged in parallel and fixed inside the shallow water tank 1. The upper surface of the upper surface is not immersed in water, and each solar power generation module 2 is connected in parallel and then connected to the...

Embodiment 2

[0031] This embodiment is similar to Embodiment 1, the difference lies in the connection mode of the solar power generation components 2, the solar power generation components 2 in this embodiment are connected in series, and the number of solar power generation components 2 is 5-30 pieces.

[0032] The working mode of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com