Electric boosting system for of smelting kiln of glass furnace

An electric fluxing and glass technology, applied in glass furnace equipment, glass production, glass manufacturing equipment, etc., can solve problems such as radiant heat control and molten glass defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

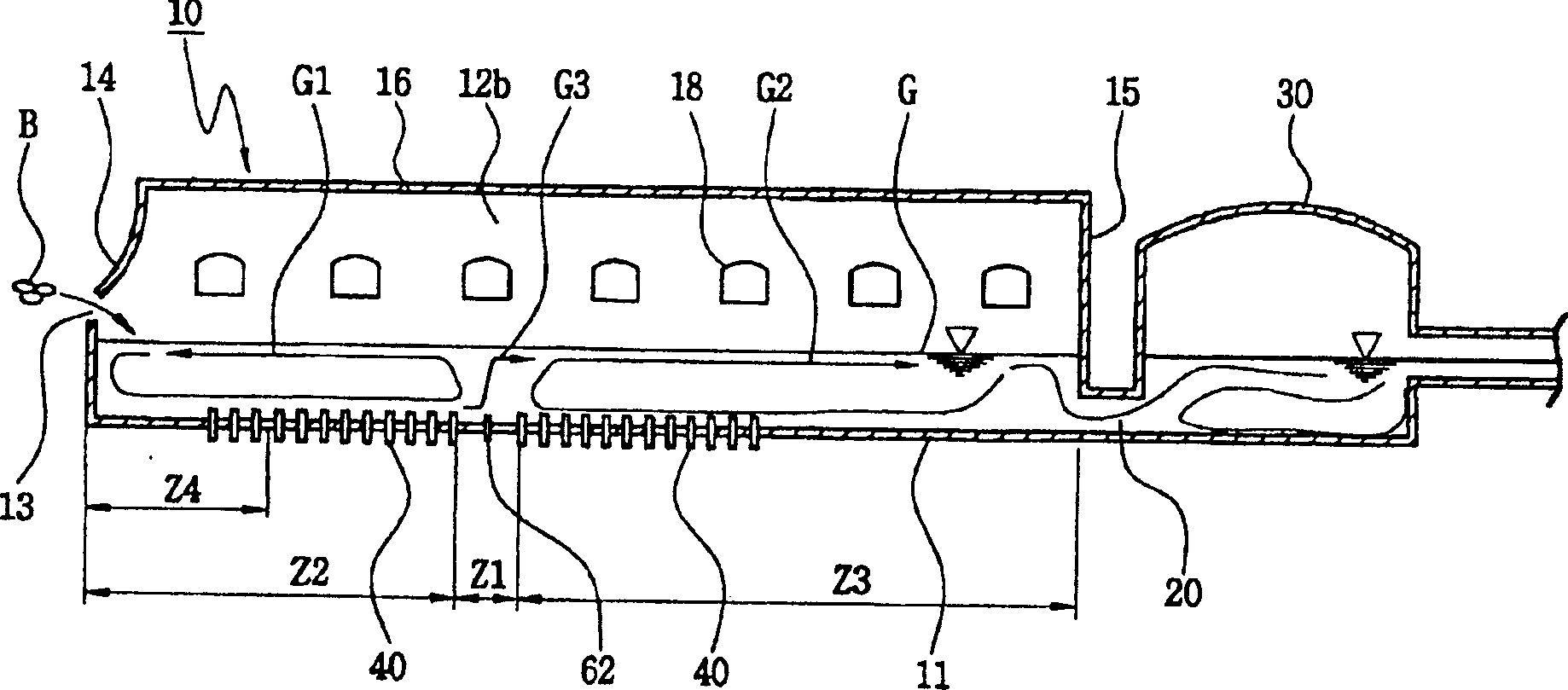

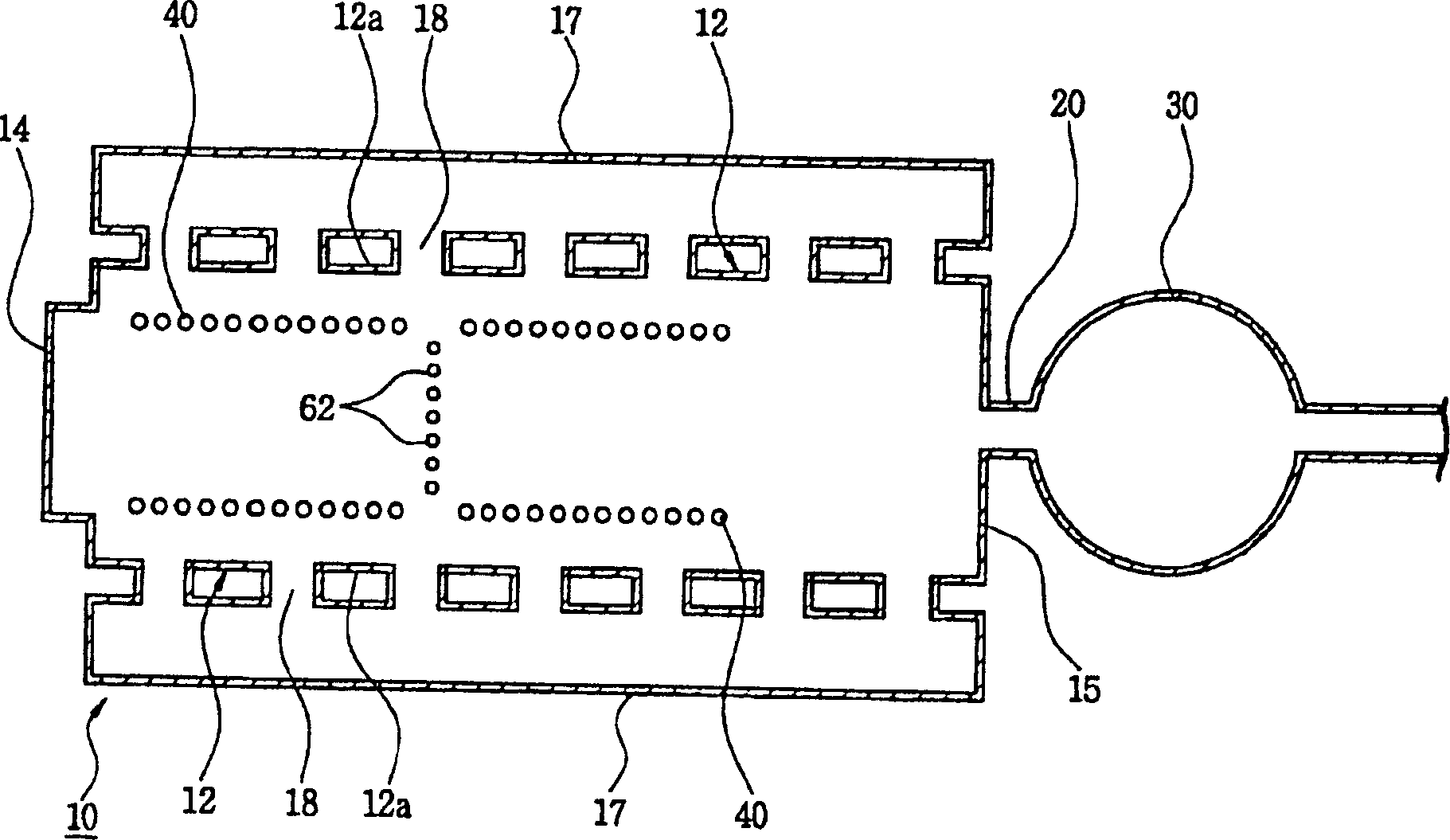

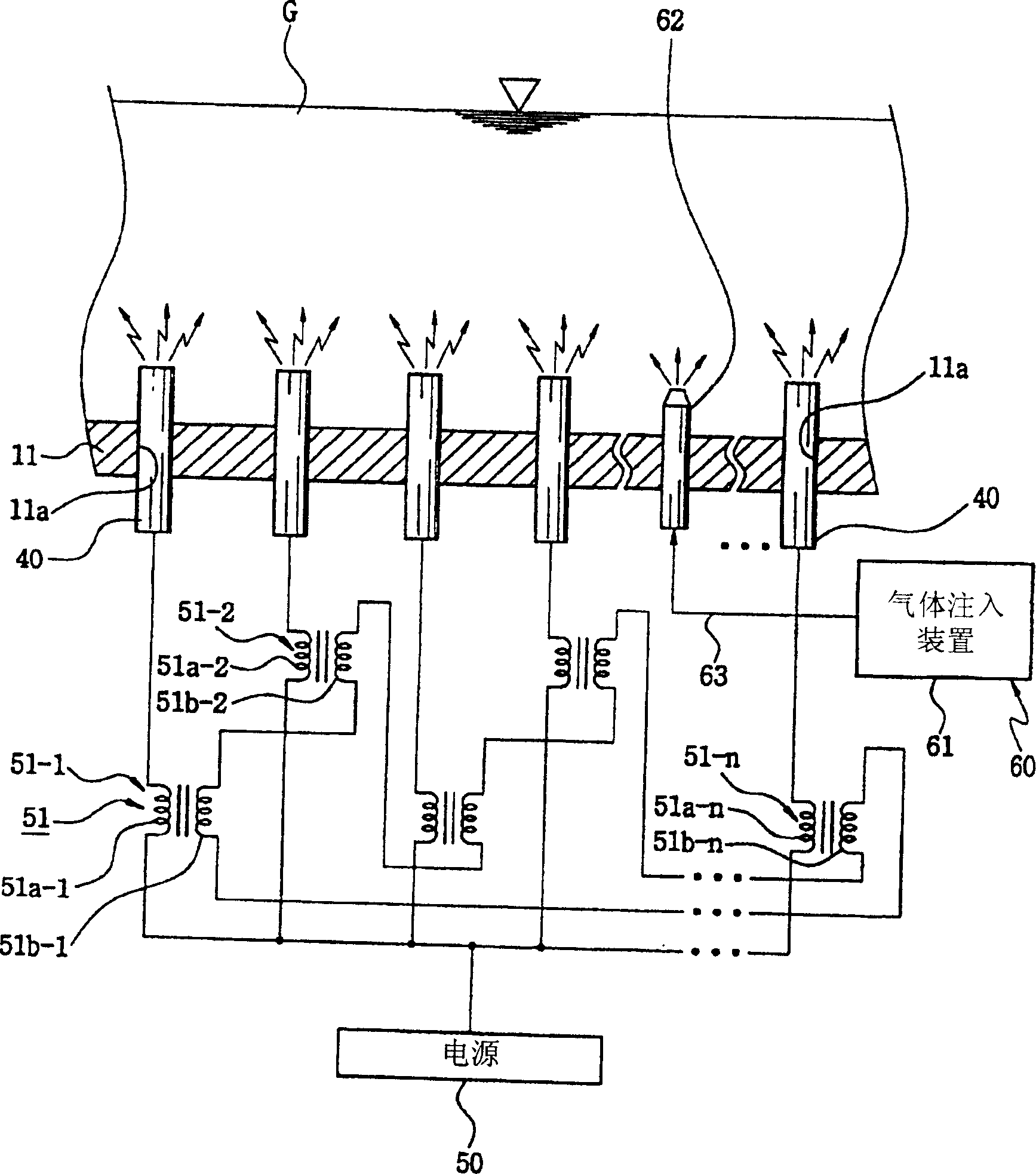

[0015] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings, in which, Figure 1 to Figure 3 The same components are denoted by the same reference numerals.

[0016] refer to figure 1 and figure 2 , according to a preferred embodiment of the present invention, the glass melting furnace includes: a melting furnace 10, which is used to melt the glass raw materials B put into it; Glass G; a refining chamber 30 connected to the downstream end of the throat 20 for removing bubbles generated inside the molten glass G and homogenizing the molten glass G.

[0017] The melting furnace 10 is composed of a bottom 11, a side wall 12, a rear wall 14, a front wall 15 and a vaulted top 16, wherein the rear wall 14 has a feeding port 13 through which glass raw material B is put into the melting furnace 10, and the front The wall 15 acts as a boundary between the furnace 10 and the throat 20 . Each side wall 12 has a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com