Dry-type removing method for sulfur trioxide and heavy metals in nonferrous smelting acid-making flue gas

A sulfur trioxide and smelting flue gas technology, which is applied in the field of flue gas purification, can solve the problems of unsuitable sulfur trioxide removal and poor sulfur trioxide removal effect, so as to reduce sulfuric acid concentration and heavy metal content, reduce generation, and reduce generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

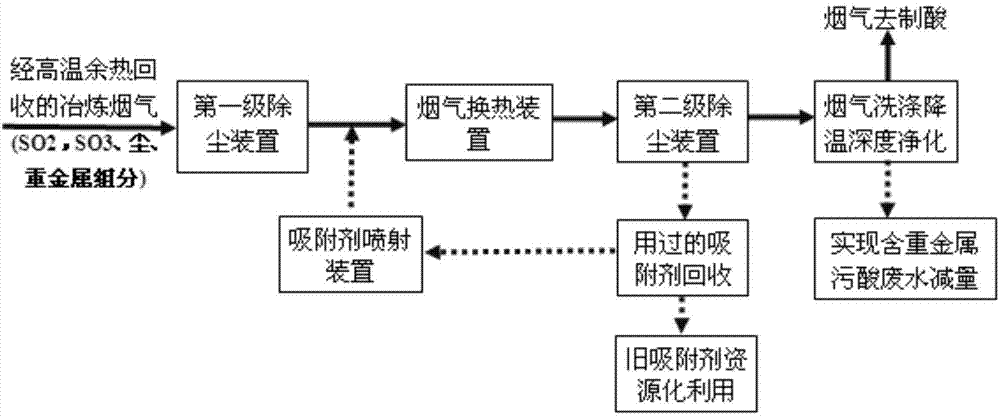

[0029] A method for dry removal of sulfur trioxide and heavy metals from flue gas from acid smelting in non-ferrous metallurgy, using such as figure 1 The shown process specifically comprises the following steps:

[0030] In the first step, after the non-ferrous metal smelting flue gas passes through the high-temperature waste heat boiler to initially recover heat, it first passes through the first-stage dust removal device for first-stage dust removal to remove more than 90% of the smoke in the flue gas;

[0031] Flue gas from non-ferrous metal smelting contains sulfur dioxide, sulfur trioxide and heavy metals, among which heavy metals are one or more of lead, mercury, arsenic, cadmium and chromium.

[0032] The first-stage dust removal device is one of electric dust collectors or high-efficiency multi-tube dust collectors; the dust collected by the first-stage dust removal device is returned to the smelting furnace or directly recycled.

[0033] The second step, using compr...

Embodiment 2

[0043] Taking simulated non-ferrous metal smelting flue gas as the treatment object, the SO in the flue gas was depleted by dry adsorption. 3 The adsorption removal experiment was carried out, the simulated flue gas volume was 1L / h, and the flue gas temperature was 200 degrees. The specific processing steps are as follows:

[0044] 1. Weigh 50 mg of calcium oxide adsorbent, place it in a fixed bed reactor, and control the temperature of the reactor within the range of 200±10 degrees through a tube furnace;

[0045] 2. Pass the simulated flue gas into the fixed bed reactor, and then pass the SO in the flue gas through the mass flow meter 3 , SO 2 The concentrations are controlled at 3000mg / m 3 and about 2%, using the flue gas sampling system to measure the SO at the inlet and outlet of the fixed bed reactor 3 , SO 2 The concentration was sampled and analyzed, and the results showed that SO 3 The removal efficiency is above 95%, while SO 2 The removal efficiency is about ...

Embodiment 3

[0048] Taking the actual flue gas of a lead smelting plant as the processing object, it leads 100m from the flue 3 / h of actual flue gas, where SO 3 The concentration is 3400-3600mg / m 3 , SO 2 The concentration of Hg is about 9-10%, and the concentration of Hg is 4-5mg / m 3 , the temperature of the flue gas is about 250 degrees, the flue gas is drawn out through a multi-tube dust collector, the temperature of the flue gas is reduced to about 150 degrees, and then the zinc oxide dry powder with a particle size of 300 meshes is sprayed into the flue gas, and the adsorbent is injected The volume is 500g / h, and the treated flue gas is finally returned to the main flue through a small bag filter. After the reaction was stable, the flue gas at the outlet of the bag filter was sampled and analyzed, and the results showed that SO 3 The removal efficiency of SO is over 90% 2 The removal efficiency of mercury is about 16%, while the removal rate of mercury has reached more than 85%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com