Method for preparing bimetallic seamless steel pipe for alkali recovery boiler

A technology for alkali recovery boilers and seamless composite steel pipes, which is applied in metal extrusion control equipment, metal processing equipment, metal extrusion and other directions, can solve the problems of two-layer metal delamination and other problems, and achieve the effect of satisfying the simultaneous deformation of the inner and outer layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

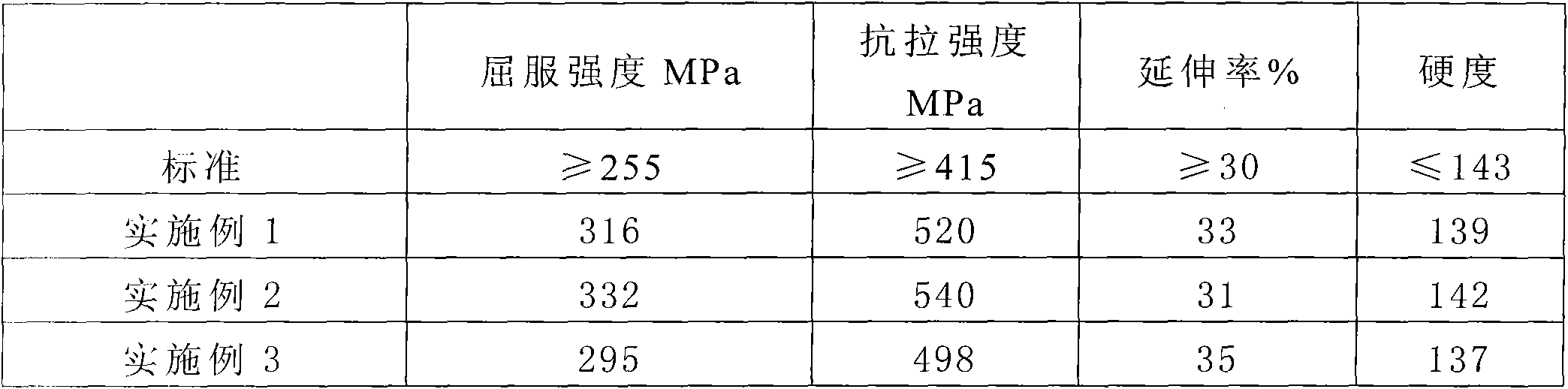

Embodiment 1

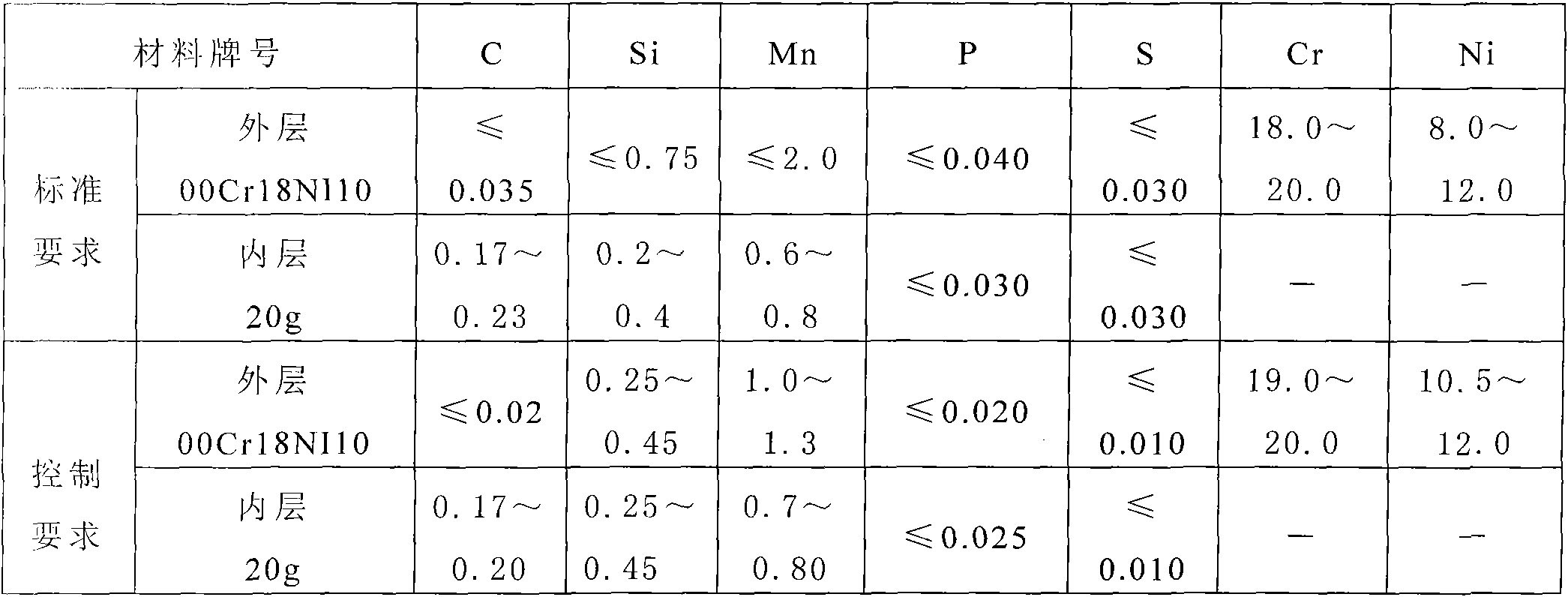

[0026] Embodiment 1 The preparation method of the double-metal seamless composite steel pipe for the alkali recovery boiler of the present invention comprises the following steps:

[0027] 1. Selection and processing of bimetallic tube blanks

[0028] 1. Billet selection: centrifugally cast 00Cr18Ni10 / 20G composite tube billet is selected. This kind of tube billet achieves preliminary metallurgical bonding and forms a large inner and outer layer bonding force. During the subsequent extrusion or extrusion + cold rolling production process, There will be no delamination or cracking due to the large shear force of the inner and outer metals.

[0029] 2. The first annealing: treatment at a temperature of 1050°C for 24 hours, the purpose is to reduce the thermal stress on the interface under the condition of a high-temperature boiler, the composition of the two-layer metal junction should have a wide gradient transition zone, and at the same time It is also to eliminate the uneven...

Embodiment 2

[0040] Example 2 The preparation method of bimetal seamless composite steel pipe for alkali recovery boiler is as follows:

[0041] 1. Selection and processing of bimetallic tube blanks

[0042] 1. Billet selection: choose centrifugal casting 00Cr18Ni10 / 20G composite tube billet.

[0043] 2. The first annealing: treatment at a temperature of 1000°C for 20 hours.

[0044] 2. Extrusion of bimetallic tube

[0045] 1. Extrusion: Use the extrusion ratio of 13 to break the grains.

[0046] 2. Billet heating system before extrusion: the billet before extrusion is heated at a temperature of 1180°C.

[0047] 3. The second annealing treatment: first heat preservation at 780°C for 2 hours, and then air cooling.

[0048] 3. Cold rolling

[0049] 1. Select an appropriate single-pass deformation amount to implement production, and the deformation amount is controlled within 40%;

[0050] 2. Reasonably distribute the deformation of each rolling pass through multi-pass rolling, so as to...

Embodiment 3

[0053] Example 3 The preparation method of bimetal seamless composite steel pipe for alkali recovery boiler is as follows:

[0054] 1. Selection and processing of bimetallic tube blanks

[0055] 1. Billet selection: choose centrifugal casting 00Cr18Ni10 / 20G composite tube billet.

[0056] 2. The first annealing: treatment at 1100°C for 30 hours.

[0057] 2. Extrusion of bimetallic tube

[0058] 1. Extrusion: Use the extrusion ratio of 17 to break the grains.

[0059] 2. Billet heating system before extrusion: the billet before extrusion is heated at a temperature of 1220°C.

[0060] 3. The second annealing treatment: first heat preservation at 800°C for 3 hours, and then air cooling.

[0061] 3. Cold rolling

[0062] 1. Select an appropriate single-pass deformation amount to implement production, and the deformation amount is controlled within the range of 55%;

[0063] 2. Reasonably distribute the deformation of each rolling pass through multi-pass rolling, so as to smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com