Novel fuel production plant and seawater desalination system for use therein

a technology of desalination system and fuel production plant, which is applied in the direction of multiple-effect evaporation, machine/engine, separation process, etc., can solve the problems of large amount of excess heat, large amount of cooling water required by steam turbines, and merit of using seawater as cooling water, so as to reduce maintenance costs and reduce the remaining salinity of produced water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

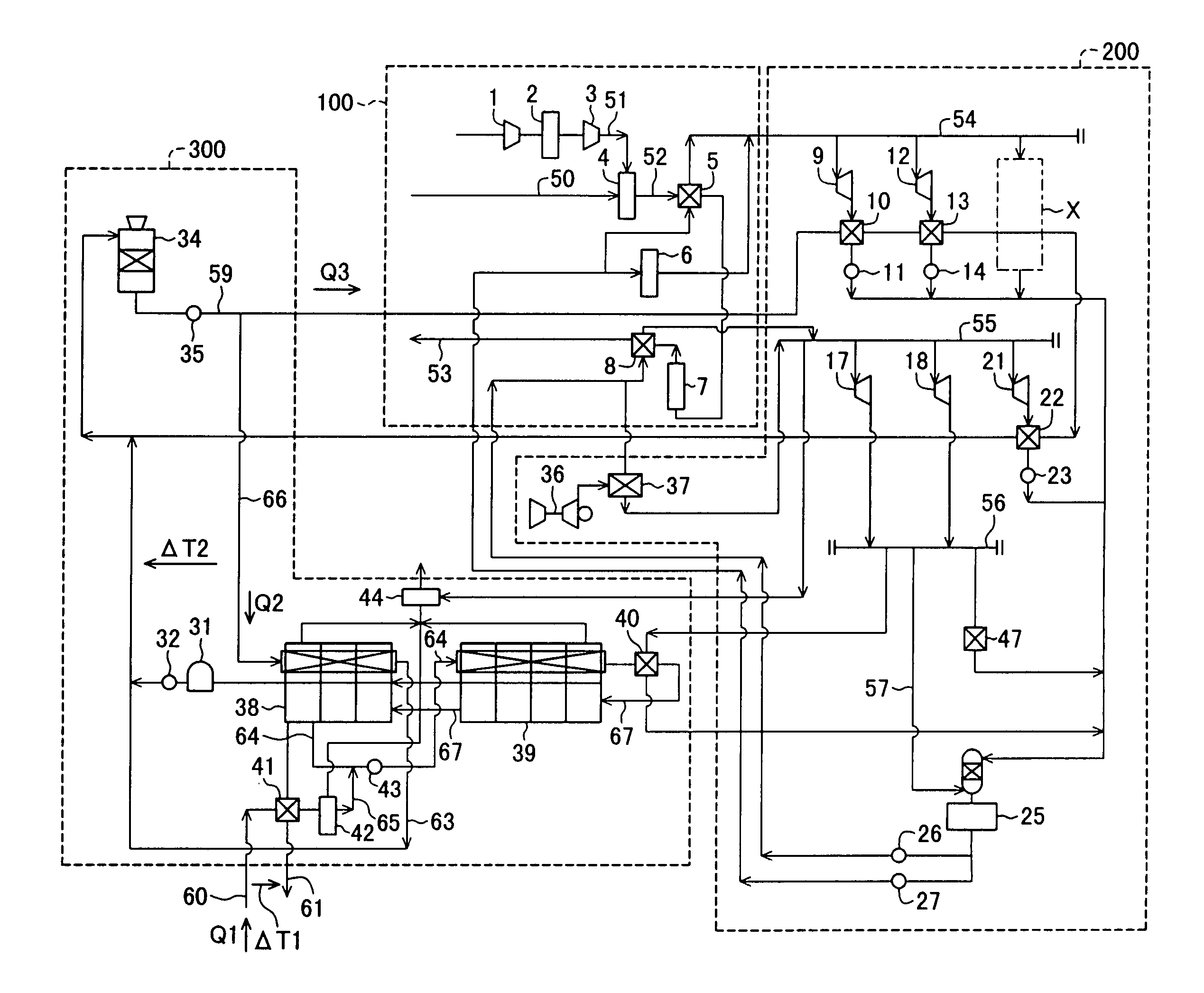

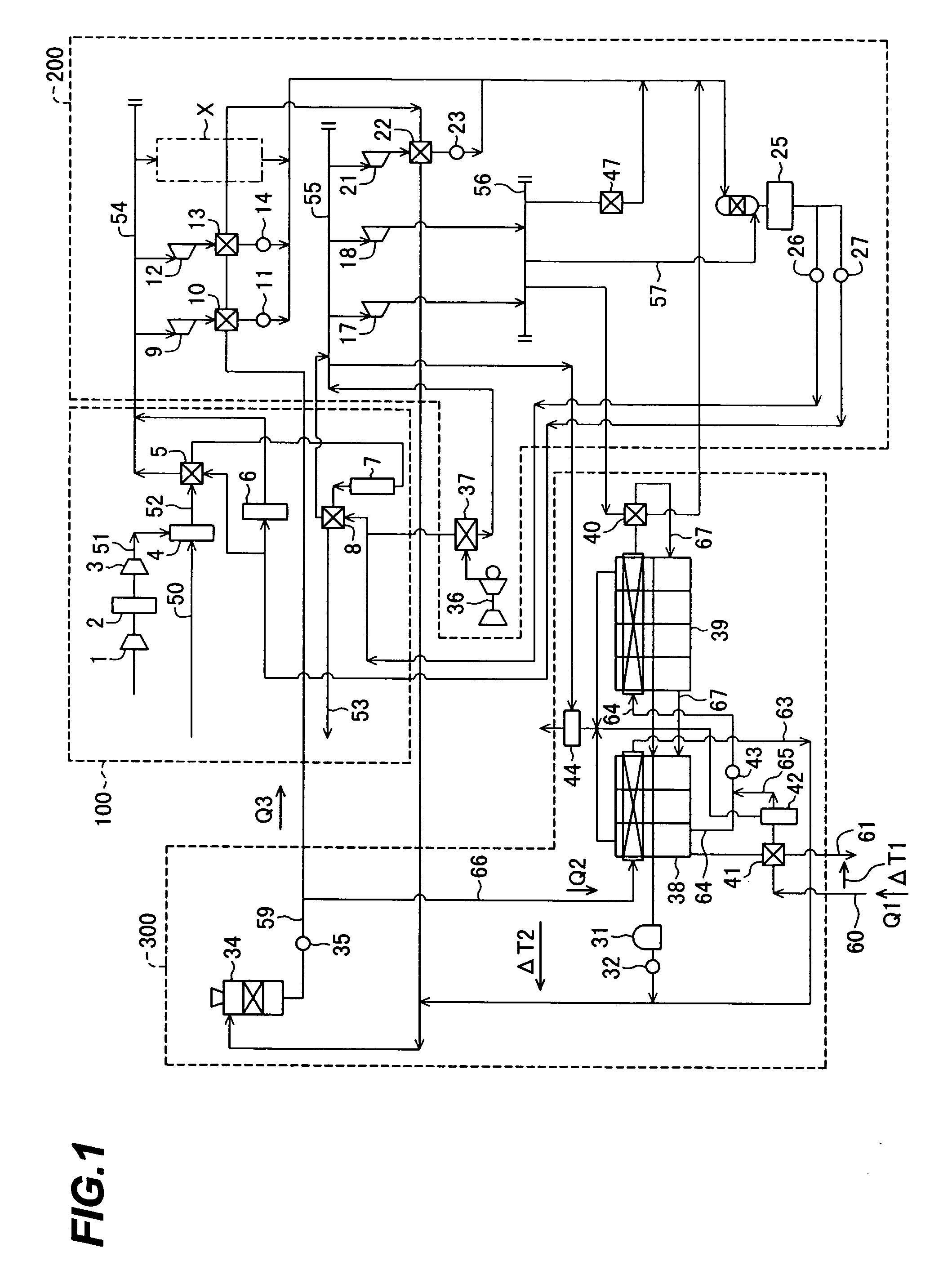

[0012] The construction of a novel fuel production plant according to one embodiment of the present invention will be described below with reference to FIG. 1.

[0013]FIG. 1 is a diagram showing the construction of the novel fuel production plant according to one embodiment of the present invention.

[0014] The novel fuel production plant of this embodiment comprises a novel fuel producing section 100, an exhaust heat utilizing section 200, and a cooling water supply section 300. The novel fuel producing section 100 produces new fuel from a feedstock and generates steam by utilizing exhaust heat. In the exhaust heat utilizing section 200, steam turbines are driven using the steam generated by the novel fuel producing section 100, to thereby drive rotary machines, etc. The cooling water supply section 300 supplies cooling water used in condensers for the steam turbines in the exhaust heat utilizing section 200.

[0015] The novel fuel producing section 100 comprises an air compressor 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com