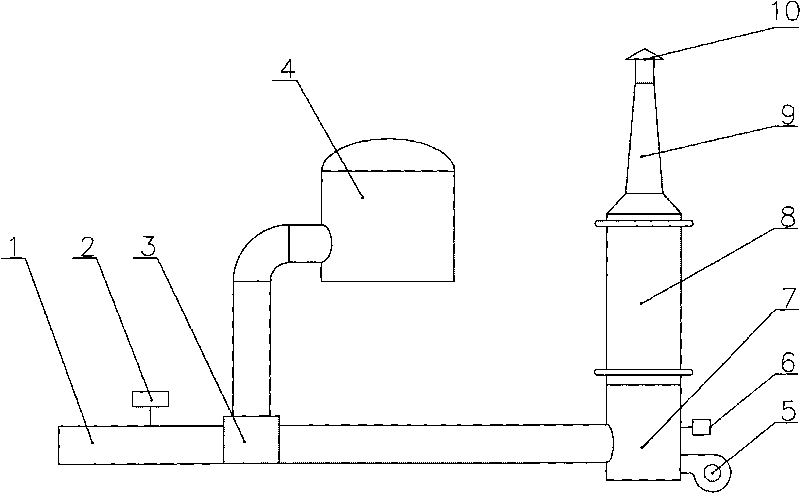

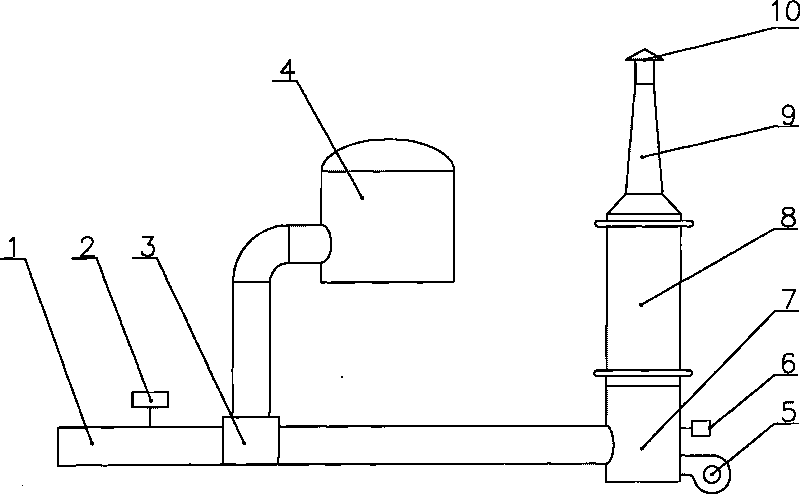

Waste heat recovery system of exhaust gas of metallurgical converter

A waste heat recovery system and gas release technology, which is applied in the field of waste heat recovery system for metallurgical converters to release gas, to achieve the effects of increasing the discharge height, smooth flue gas circulation, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A 40-ton converter, when the CO concentration is lower than 30%, is switched into the combustion chamber 7 by the three-way valve 3, after the supplementary air combustion, high-temperature flue gas is produced, and the flue gas volume is 48000Nm 3 / h, the flue gas temperature is 1200℃. The combustion chamber 7 has a diameter of 3.5m and a height of 5.5m. A membrane wall is provided in the combustion chamber 7 as a radiant heat exchange surface to absorb the radiant heat of CO combustion and reduce the temperature of the furnace wall of the combustion chamber 7 at the same time. The flue gas enters the waste heat recovery boiler 8 after radiating heat exchange through the combustion chamber 7. The waste heat recovery boiler 8 has a diameter of 3.5m and a height of 12m. After the flue gas passes through the waste heat recovery boiler 8, the temperature drops to 200°C, and is discharged into the atmosphere through the exhaust chimney 9, and at the same time, 0.6Mpa saturate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com