Process method for circularly utilizing waste water produced by butadiene preparation through butene oxidative dehydrogenation

A technology of oxidative dehydrogenation and process method, which is applied in the chemical industry, can solve problems such as the clogging of the spray head, and achieve the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

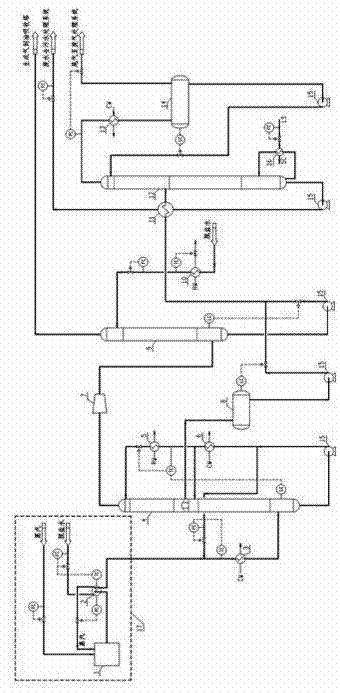

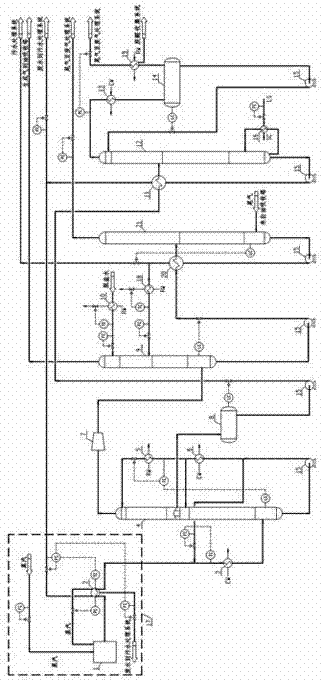

Method used

Image

Examples

Embodiment 1

[0022] The oxidation unit of the butadiene plant with an annual output of 100,000 tons of butene oxidative dehydrogenation adopts the aldehyde washing wastewater circulation process of the present invention. After being treated by the stripping tower, about 50% of the wastewater enters the aldehyde washing tower to wash aldehyde, and the rest of the wastewater is sent to In the sewage treatment system, the aldehyde washing tower supplements part of the desalinated water; and the waste water from the acid washing process is sent to the sewage treatment system after being treated by the waste water distillation tower. The effect is:

[0023] The amount of desalted water to be added to the aldehyde washing tower is: 30 tons / hour

[0024] The amount of desalted water to be added to the waste heat boiler is: 62.5 tons / hour

[0025] The amount of wastewater to be treated by the sewage treatment system is: 112.3 tons / hour

[0026] When the waste water from the butadiene oxidation u...

Embodiment 2

[0032] The oxidation unit of the butadiene plant with an annual output of 100,000 tons of butene oxidative dehydrogenation adopts the acid washing wastewater circulation process of the present invention. After the acid washing wastewater is treated in the wastewater distillation tower, about 50% of the wastewater enters the waste heat boiler and then enters the steam produced Reactor, the rest of the wastewater is sent to the sewage treatment system for treatment; the aldehyde washing wastewater is treated by the stripping tower, and all of it is discharged into the sewage treatment system. The effect is:

[0033] The amount of desalted water to be supplemented by the aldehyde washing tower is: 66.5 tons / hour

[0034] The amount of desalted water to be added to the waste heat boiler is: 25 tons / hour

[0035] The amount of wastewater to be treated by the sewage treatment system is: 111.3 tons / hour

[0036] When the waste water from the butadiene oxidation unit produced by the...

Embodiment 3

[0042] The oxidation unit of the butadiene plant with an annual output of 100,000 tons of butene oxidative dehydrogenation adopts the recycling process of acid washing wastewater and aldehyde washing wastewater of the present invention. After the acid washing wastewater is treated by the wastewater distillation tower, about 50% of the wastewater enters the waste heat boiler and The production steam enters the reactor again, and the remaining wastewater is sent to the sewage treatment system for treatment; after the aldehyde washing wastewater is blown off, about 50% is returned to the aldehyde washing tower for washing aldehyde recycling, and the rest of the wastewater is sent to the sewage treatment system, and a small amount of aldehyde washing tower is replenished desalinated water. The effect is:

[0043] The amount of desalted water to be added to the aldehyde washing tower is: 30 tons / hour

[0044] The amount of desalted water to be added to the waste heat boiler is: 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com