Welding device for automobile swing arm welding assembly and swing arm welding forming method of welding device

A technology of welding device and automobile swing arm, which is applied in the direction of auxiliary devices, welding accessories, welding equipment, etc., can solve the problems of excessive weld seam, low work efficiency, easy fatigue, etc., achieve precise welding, realize welding automation, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

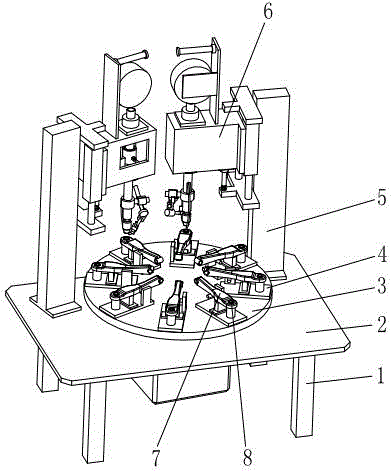

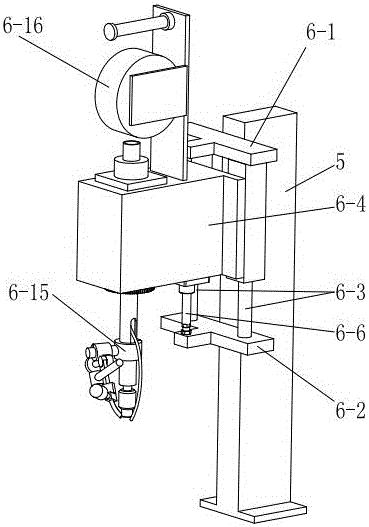

[0030] see Figure 1 to Figure 6 , the present invention provides a welding device for an automobile swing arm welding assembly, comprising a body 1, the body 1 is provided with a workbench 2, the workbench 2 is provided with a rotary table 3, and the rotary table 3 is fixed with a plurality of circularly distributed The clamp device 4; the workbench 2 is provided with at least one column 5, and the upper end of the column 5 is fixedly provided with a welding device 6, and the welding device 6 is above the clamp device 4;

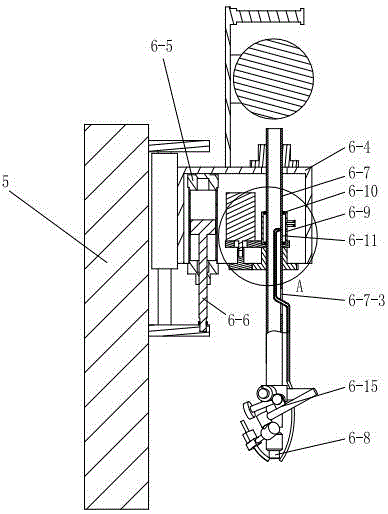

[0031] Described welding device 6 comprises upper base body 6-1, lower base body 6-2 that are fixed on column 5, guide bar 6-3 that connects upper base body 6-1 and lower base body 6-2, and is arranged on guide bar 6-3 and the frame 6-4 that can move axially along the guide rod 6-3, the frame 6-4 is fixed with a cylinder 6-5, and the stroke rod 6-6 of the cylinder 6-5 is connected with the lower seat body 6 -2; The frame 6-4 is provided with a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com