Automatic welding assembly mechanical arm

An automatic welding and assembly machinery technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to realize automatic micro-adjustment, inability to realize complete automation, and lower welding accuracy, so as to achieve welding Accuracy, ease of movement, and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

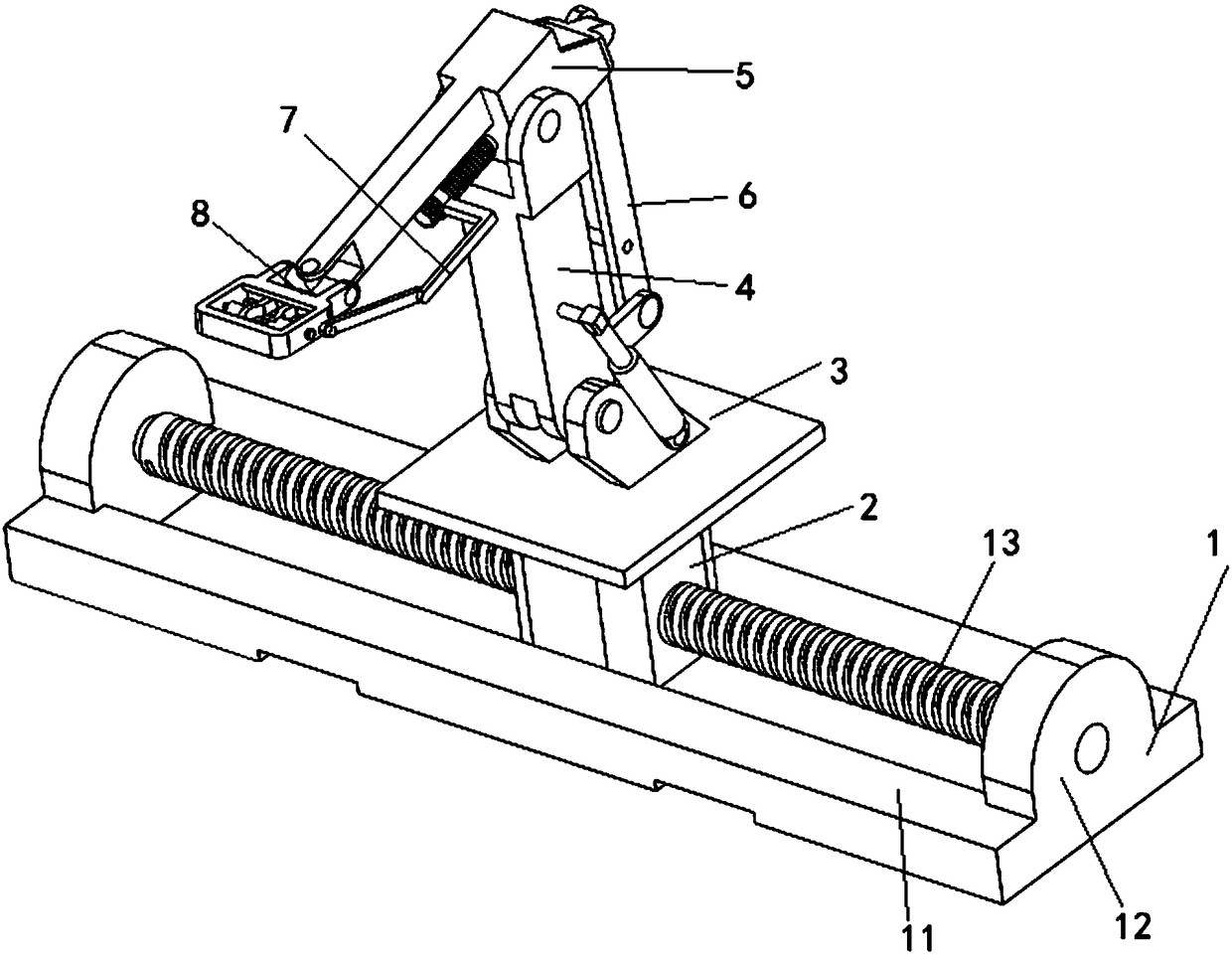

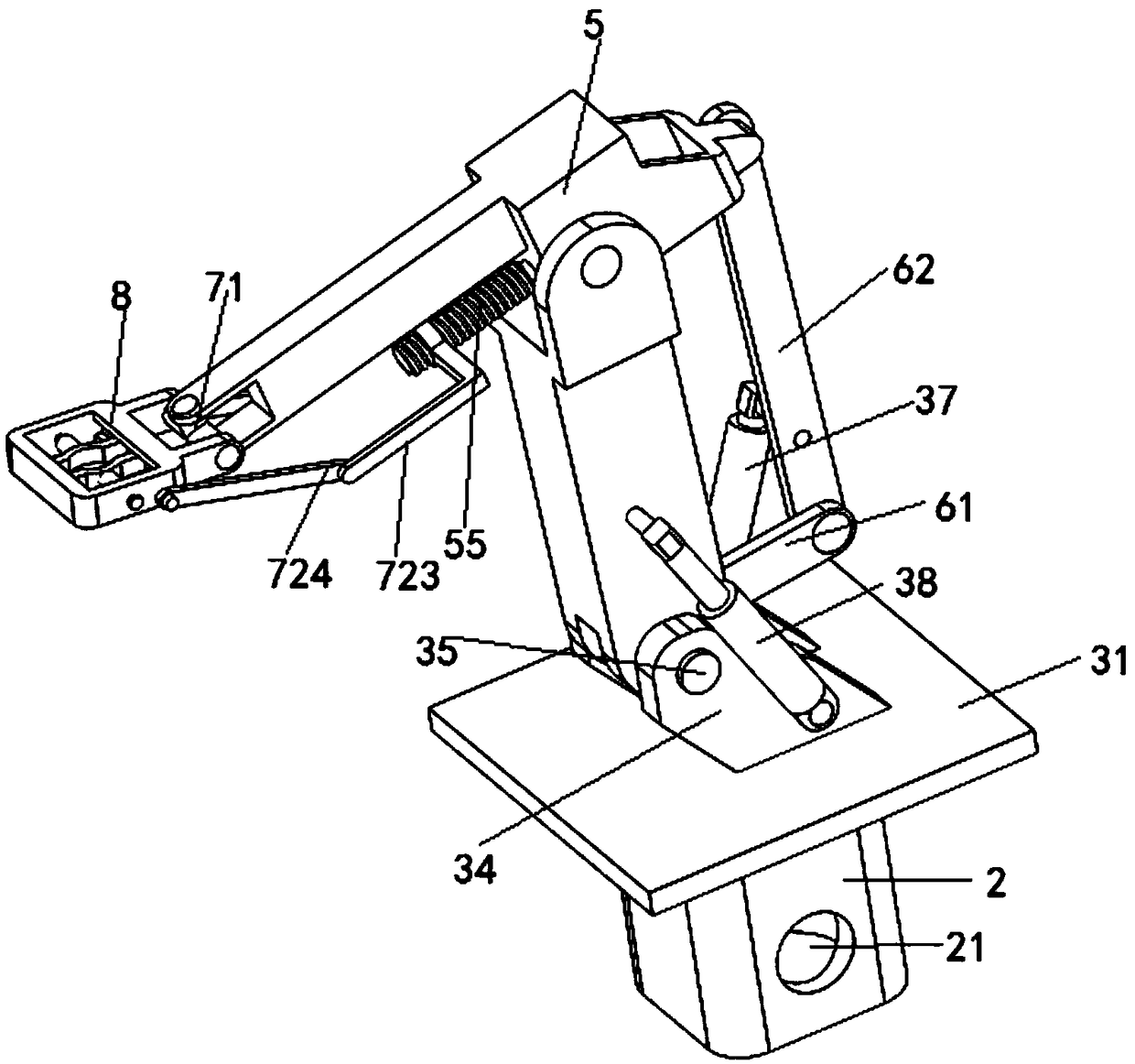

[0033] An automated welding and assembly manipulator, such as figure 1 , figure 2 As shown, it includes a sliding fixed seat 1 and an all-round welding tool installed and fixed on the sliding fixed seat 1;

[0034] Such as image 3 As shown, the all-round welding tooling includes from bottom to top the fixed positioning cylinder 2, the first joint seat 3, the second joint seat 4 and the third joint seat 5;

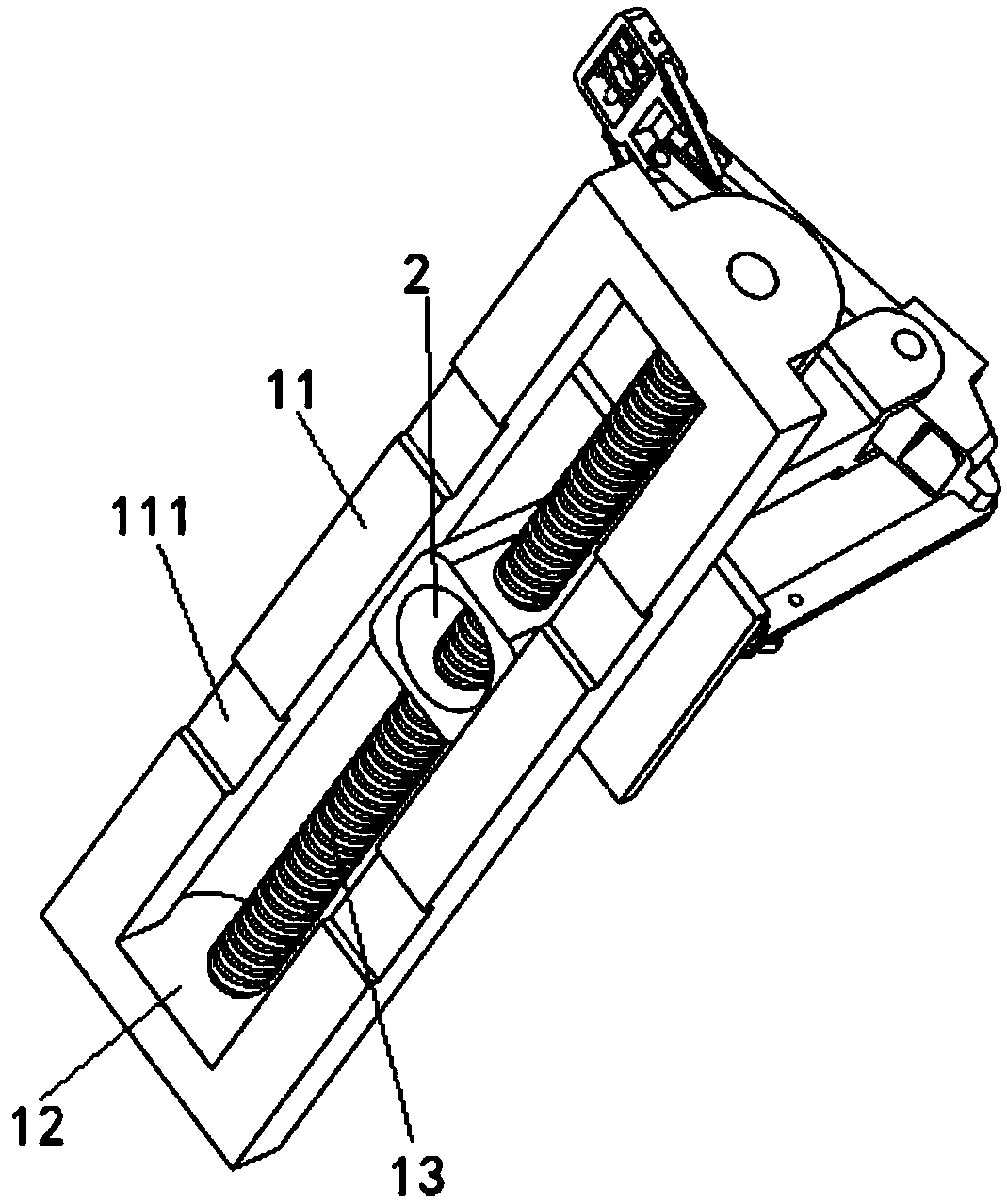

[0035] Such as Figure 4 and Figure 5 As shown, the sliding fixed seat 1 includes two oppositely arranged suction strips 11, the two ends of the two suction strips 11 are respectively connected and fixed by fixing blocks 12, and the bottom surfaces of the two suction strips 11 are provided with a number of first An installation groove 111, an electromagnet is installed and fixed in the first installation groove 111, the entire welding assembly mechanical arm is fixed on the surface of the welding workpiece by electromagnet attraction, and a first transmission screw 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com