Method for guiding robot to conduct automatic welding through CAD drawing technology

An automatic welding and robot technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as forgetting, achieve shortened cycle, improve working conditions, and realize the effect of welding automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below with reference to accompanying drawing and embodiment:

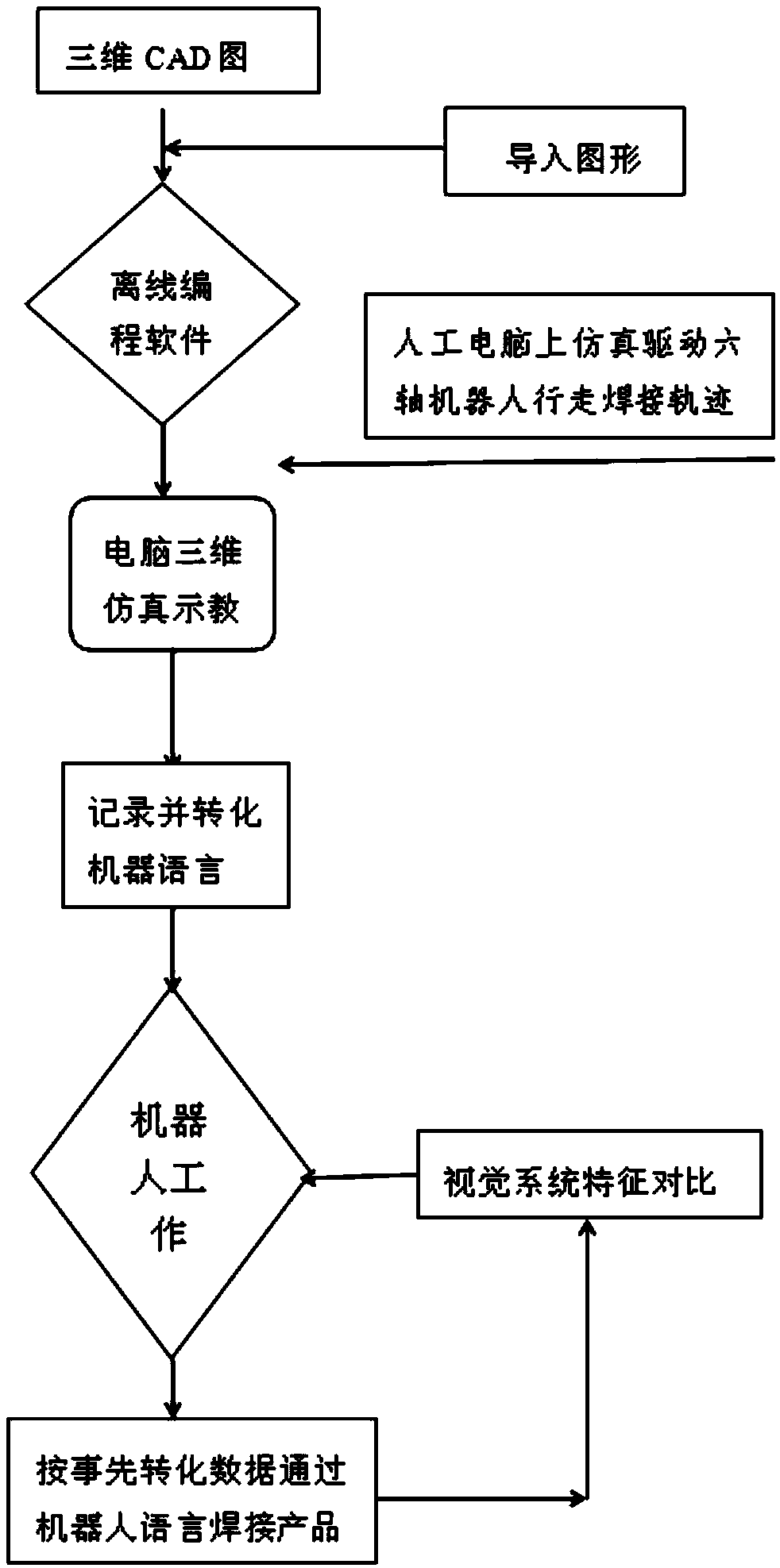

[0044] attached figure 1 It can be seen that a CAD drawing technology guides the robot automatic welding method,

[0045] On the 3D CAD weld seam drawing, the simulation teaching is carried out through the 3D drawing, and the movement trajectory and posture of the 6-axis robot of the 3D simulation are directly marked;

[0046] Convert the above trajectory and posture into a robot program or a language that the robot can understand through coordinate transformation;

[0047] The robot receives control instructions, uses the vision system camera to identify the feature points of the workpiece, and guides the robot to complete welding.

[0048] Generate 3D CAD drawings of processed products and import 3D CAD drawings into the control system;

[0049] The control system performs simulation drive; generates a six-axis robot walking welding trajectory;

[0050] Disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com